Tlhaloso ea Sehlahisoa

Beha: ka tlase ho 300 ℃

Welding: ka tlase ho 600 ℃

Ring: ka tlase ho 1000 ℃

Silicon Carbide: ka tlase ho 1300 ℃

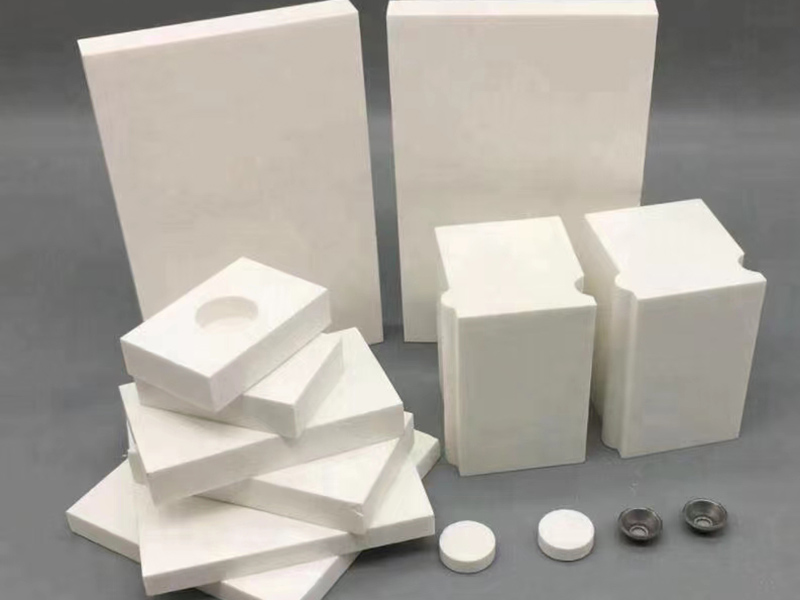

Karolo e ka sehloohong ea SHC e manganga ceramic ke92% Alumina & 95% Alumina Ceramic e nang le ts'ebetso e ntle haholo le theko e ntle le thepa e sebelisoang ka ho fetisisa. Boima bo phahameng, boima bo kang ba daemane, lijo-thollo tse ntle tse hlophisitsoeng le matla a phahameng a mochine ke thepa e ikhethang e etsang hore e be thepa ea khetho bakeng sa mefuta e mengata ea likopo tse hlokahalang. Ka lebaka la thepa ea ho itšireletsa, hangata e sebelisoa lihlahisoa tsa elektronike.

Litlhaloso tsa tekheniki tsa tile ea ceramic

Litaba tsa AL2O3: >92%

Boima: 3.6g/cm3

Ho thatafala ha Rockwell: HRA 85

Ho qhoma ho thata: 4 MPa.ml/2

Matla a hananang le khatello:> 850 MPa

E hanyetsanang le ho kobeha: 300 MPa

Thermal conductivity: 24 W / mK

Coefficient ea ho eketsa mocheso: 50-83 10-6 m/mK

Molemo oa Sehlahisoa

1. Ho hanyetsa ka mokhoa o motle:ho amohela lirafshoa tse thata tsa alumina e le liner, nako ea bophelo ba phala e ka holimo ho makhetlo a 10 ho feta tšepe e tloaelehileng e thata.

2. Corrosion resistance:alumina ceramic e na le melemo ea khoholeho ea metsi a leoatle, ho hanyetsa acid le alkali, hape ho sireletsa tšireletso.

3. Khothatso ea likhohlano:Sebaka se ka hare se boreleli ebile se se na khoholeho ea mobu, boreleli ba ka hare ba liphaephe bo phahametse liphaephe tse ling tsa tšepe.

4. Boima bo bobebe:Boima ba peipi e kopantsoeng ea phala ea ceramic e sa tsoa fihla halofong ea phala ea majoe le hoo e ka bang 50% ea phala ea alloy. Ka ho hanyetsa le kutu, nako ea bophelo ea pipe e entsoeng ka ceramic e telele ka mokhoa o tsotehang ho feta liphaephe tse ling tse sa sebetseng, ka hona, litšenyehelo tsa ho kopanya le ho sebetsa 5. Ho bokana ha bonolo: Ka lebaka la boima ba eona bo bobebe le bokhoni bo botle ba weld, e ka bokelloa habonolo ka ho kopanya kapa ho kopanya flange le ho fokotsa ka mokhoa o tsotehang.