Ho khetha tokeloMechini e silafatsang mohlaharee bapala karolo ea bohlokoa molemong oa ts'ebetso. Mechini ena e bohlokoa liindastering tse kang tsa merafo le tsa kaho, moo limatlafatsa tlhahiso ka ho pshatla disebediswa tse kgolo. Likarolo tsa bohlokoa, joalo ka theknoloji e tsoetseng pele le mekhahlelo ea moralo, li ama ts'ebetso le ts'epahalo haholo. Mohlala, mechini e nang le li-drive tsa hydraulic le liphanele tsa taolo tse bonolo ho basebelisi li ka eketsa tlhahiso le ho fokotsa nako ea ho theoha. Ho feta moo, ho utloisisa mefuta e fapanengdikarolo tsa mohlahare, ho kenyeletsalikarolo tsa ho roala mohlahare, ke ea bohlokoa bakeng sa tlhokomelo le bophelo bo bolelele. Phapang pakeng tsa mefuta le mefuta, joalo ka boholo ba phepelo le motsamao, e boetse e susumetsa ts'ebetso ea mochini o silafatsang mohlahare, ha ho ntse ho nahanoa ka bohlokoa badikarolo tsa rock crusherlecone crusher likarolo tse lingbakeng sa katleho ea ts'ebetso ka kakaretso.

Lintlha tsa bohlokoa

- Ho khetha sefate se nepahetseng sa mohlaharee ntlafatsa ts'ebetso ea ts'ebetso. Tsepamisa maikutlo ho likarolo tse kang ho senya matla le ho khoneha ho finyella litlhoko tsa hau tse khethehileng.

- Lisebelisoa tsa boleng bo holimo, joalo katšepe e phahameng ea manganese, ntlafatsa ho tšoarella le nako ea bophelo. Khetha mechine e hahiloeng ka thepa e matla ho fokotsa ho senyeha le ho senya.

- Tlhokomelo ea kamehla ke ea bohlokoa bakeng sa ts'ebetso. Etsa tlhahlobo 'me u boloke likarolo tse ling li fumaneha habonolo ho fokotsa nako le litšenyehelo tsa ho lokisa.

- Ho utloisisa sekhahla sa ho senya le ho fokotsa tekanyo ho thusa ho khetha mochine o nepahetseng. Netefatsa hore mohlala o tsamaisana le lipheo tsa hau tsa tlhahiso bakeng sa liphetho tse nepahetseng.

- Ts'ehetso ea ka mor'a thekiso, ho kenyelletsa le liwaranti le koetliso, ke ea bohlokoa. Sistimi e matla ea tšehetso e matlafatsa boleng ba mochini le ho netefatsa ts'ebetso e sebetsang.

Rala le ho Aha Boleng ba Mechini ea Jaw Crusher

Themoralo le ho aha bolengea metjhini e hlabang mohlahare e susumetsa haholo tshebetso ya bona le ho phela halelele. Baetsi ba etelletsa pele ho sebelisa thepa ea boleng bo holimo ho matlafatsa nako e telele. Mohlala, tšepe e phahameng ea manganese e ka fana ka nako ea bophelo e joalo30-50% nako e teleleha e bapisoa le lisebelisoa tse tloaelehileng. Khetho ena ea thepa ha e ntlafatse nako e telele feela empa e boetse e tiisa hore mechine e khona ho mamella mathata a tšebeliso e boima.

Lintho Tse Sebelisitsoeng

Baetsi ba holimo ba tsepamisa maikutlo hopopontshwa moralong wa sehlahiswa. Ba tsetela ho lipatlisiso le nts'etsopele ho theha theknoloji e tsoetseng pele le lisebelisoa. Boitlamo bona bo lebisa ho metjhini e silafatsang mehlahare e sebetsang hantle le e tšepahalang. Ho thatafala le ho khopama ha thepa ea phepelo le hona ho phetha karolo ea bohlokoa ho litekanyetso tsa ho apara, ho susumetsa nako ea bophelo ea lisebelisoa. Ho hlahlojoa khafetsa ho ka lelefatsa bophelo ba karolo ea 30%, ho eketsa nako ea bophelo ka kakaretso ka tlhokomelo e matla.

Botšepehi ba Sebopeho

Botšepehi ba sebopeho bo bohlokoa molemong oa katleho ea ts'ebetso ea mechini e silafatsang mehlahare. Liforeimi tse matla le tse entsoeng hantle li thibela deformation tlas'a meroalo e boima. Boleng bona bo netefatsa hore mechini e boloka ts'ebetso ea eona ka nako. Ho sebelisa likarolo tse sa sebetseng ho ka fokotsa tse ling ka 35%, ho fokotsa nako le ho lelefatsa nako ea ts'ebetso. Tšebelisano lipakeng tsa lipoleiti tsa mohlahare le likaroloana tsa lintho tse bonahalang li lebisa moaparong oa bohlokoa, o ka fokotsang ts'ebetso le ho eketsa tšebeliso ea matla.

Portability Features

Likarolo tsa portability li bohlokoa bakeng sa liindasteri tse ngata. Mochini o nkehang habobebe oa ho pshatla mohlahare o lumella ho tsamaisa habonolo lipakeng tsa libaka tsa mosebetsi. Ho tenyetseha hona ho ka ntlafatsa tlhahiso le ho fokotsa litšenyehelo tsa ts'ebetso. Bahlahisi ba Elite ba fana ka mefuta e mengata ea li-crusher tse etselitsoeng mesebetsi e fapaneng, ho bonts'a kutloisiso ea bona ea litlhoko tse fapaneng tsa mmaraka. Ho feta moo, litsamaiso tse matla tsa ts'ehetso, ho kenyelletsa phihlello e potlakileng ea likarolo tse ling le tlhokomelo, li bohlokoa bakeng sa ho fokotsa nako.

Metrics ea Ts'ebetso ea Mechini ea Jaw Crusher

Metrics ea ts'ebetsobapala karolo ea bohlokoa ho lekola mechini e pshatlang mohlahareng. Melemo ena e thusa basebelisi ho utloisisa hore na mochini o ka sebetsa hantle hakae lits'ebetsong tse fapaneng. Lintlha tse tharo tsa bohlokoa tsa ts'ebetso li kenyelletsa matla a ho senya, tekanyo ea phokotso, le ho sebetsa hantle ha matla.

Bokhoni ba ho hatakela

Bokhoni ba ho pshatla bo bolela palo ea lintho tse silafatsoang ke sefate sa mohlahare ka nako e itseng. Metric ena e bohlokoa bakeng sa ho tseba hore na mochini o loketse mesebetsi e itseng. Mefuta e fapaneng e bonts'a bokhoni bo fapaneng ho ipapisitse le moralo oa bona le liparamente tsa ts'ebetso.

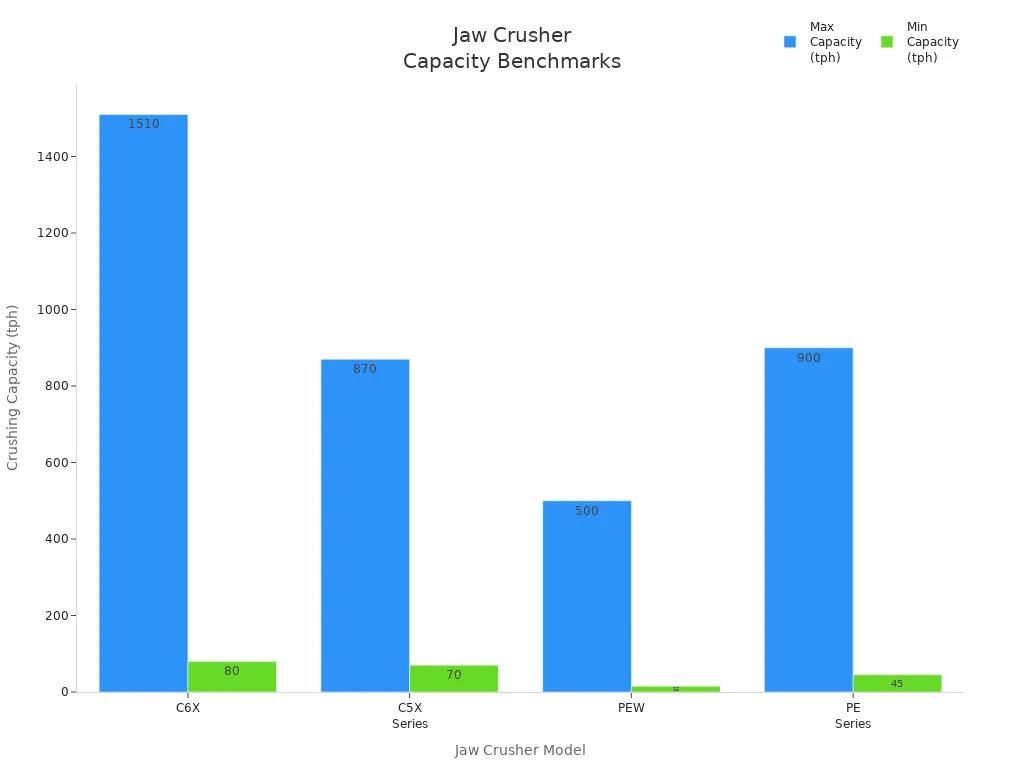

Tafole ke ena e bonts'ang bokhoni ba ho qhekella ba mefuta e tsebahalang ea ho senya mohlahare:

| Mohlala | Kenyeletso ea Boholo | Bokhoni (tph) | Lisebelisoa |

|---|---|---|---|

| C6X | 0-1280 limilimithara | 80-1510TPH | Merafo e meholo, merero ea meralo ea motheo |

| Letoto la C5X | 0-920 limilimithara | 70-870TPH | Lits'ebetso tse mahareng ho isa ho tse kholo |

| MOKHOA | 80-1510TPH | 15-500TPH | Meepo ea maemo a mahareng, tlhahiso e kopaneng |

| Letoto la PE | 0-1020mm | 45-900TPH | Ts'ebetso e nyane ho isa ho e mahareng |

Tse ngatanyanamabaka a susumetsa matla a ho senya, ho kenyelletsa:

- Moqapi oa mochini o senyang: Mefuta e fapaneng, joalo ka mefuta ea Dodge le Blake, e na le meralo e ikhethang e amang bokhoni.

- Lenaka pakeng tsa mehlahare: Ho fokotseha ha angle ho ka fokotsa ho kopana ha lefika, ho ama bokhoni.

- Lebelo la ts'ebetso: Ho fapana ha lebelo ho ka ama bokhoni, ka litlamorao tse fapaneng ka lebelo le tlase le le phahameng.

- Boemo ba lifahleho tsa mohlahare: Ho apara le boemo ba lifahleho tsa mohlahare li ka susumetsa bokhoni ba ho senya.

- Boemo ba ho sisinyeha ha mohlahare: Li-amplitudes tse kholo li ka lebisa keketseho e potlakileng ea lithane tsa theoretical, tse amang tlhahiso ea sebele.

- Bokhohlaha ba mohlahare: Keketseho e mpe e ka fokotsa ho lula ha sebaka sa phalliso, ea ama bokhoni.

Karolelano ea Phokotso

Karo-karolelano ea phokotso e lekanya hore na sefate sa mohlahare se fokotsa boholo ba thepa ea ho kenya. Karolelano ena e bohlokoa bakeng sa ho utloisisa katleho ea ts'ebetso ea ho senya. Li-crushers tsa mohlahare tse sebetsang ka holimo hangata li finyella akarolelano ea phokotso ho tloha ho 6:1 ho isa ho 8:1bakeng sa li-crusher, 3:1 ho isa ho 5:1 bakeng sa li-crushers tsa bobeli, le 2:1 ho isa ho 3:1 bakeng sa li-crushers tsa thuto e phahameng.

Karolelano ea phokotso e susumetsa haholo ts'ebetso ea li-crushers tsa mohlahare ka ho khetholla boholo ba thepa e hlahisoang le matla a tlhahiso. Kamore e khangoang e ntlafatsa bokhoni ba tlhahiso le ho netefatsa boholo ba likaroloana. Ka lehlakoreng le leng, kamore e sa chekeng e ka lebisa ho fokotseng ts'ebetso le sebopeho se fokolang sa likaroloana.

- Kamore e khangoang e eketsa bokhoni ba tlhahisomme e hlahisa dikarolwana tse robehileng ka ho tshwana.

- Kamore e sa khakeng e ka fokotsa ts'ebetso mme ea ama sebopeho sa likarolo hampe.

Li-crushers tsa mohlahare tse feptjoang ke tsa bohlokoa bakeng saho eketsa bokhoni ba tlhahisole ho etsa bonnete ba ho robeha ha likaroloana tse tšoanang. Ka lehlakoreng le leng, ho fepa ka mokhoa o fokolang ho ka lebisa likotlong tse fokolang empa ho ama hampe sebopeho sa likaroloana le bokhoni ba tlhahiso, 'me qetellong ho sitisa katleho.

Matla a Matla

Matla a matla ke metric ea bohlokoa ea ts'ebetso bakeng sa mechini ea li-crusher tsa mohlahare. Lintlafatso tsa sejoale-joale li shebane le ho ntlafatsa tšebeliso ea matla ha li ntse li boloka ts'ebetso e phahameng. Litlhahiso tsa bohlokoa li kenyelletsa:

- Sistimi e kopaneng ea ho khanna e ntlafatsang tšebeliso ea matla.

- Li-parameter tse feto-fetohang tse fokotsang tšebeliso ea matla.

- Tsepamiso ea ts'ebetso ea ts'ebetso ea merafo.

Mohlala, li-crushers tse nyalisitsoeng tsa RM Group li fumana phokotso ea 25% ea litšenyehelo tsa mafura ha li bapisoa le mefuta ea setso. Poloko ea mafura e ka fihla ho 50% ha e kopantsoe le li-skrini tse nyalisitsoeng.

Lintlafatso tsa morao-rao li boetse li kenyelletsa:

- Litlhophiso tsa Hydraulic wedge bakeng sa liphetoho tse bonolo.

- Li-motor tse kholo tse sebetsang hantle haholo.

- Likarolo tse ntlafalitsoeng tsa polokeho le ts'ebetso.

Li-crusher tsa sejoale-joale tse sebetsang hantle haholo, joalo ka C6X, li etselitsoe ho ntlafatsa tšebeliso ea matla. Lintlafatso tsa moralo li lebisa ntlafatsong ea ts'ebetso e akaretsang.

Tafole ke ena e bapisang litekanyetso tsa tšebeliso ea matla har'a mefuta e tsebahalang ea li-jaw crusher:

| Compressive Strength (MPa) | Tšebeliso ea Motlakase (E amanang) |

|---|---|

| 28 | 1 |

| 90 | 4 |

Lintlafatso tsena li kenya letsoho holikhahla tsa khabone li fokotsehilele ho ikamahanya le ho tiisa melaoana ea moshoelella indastering.

Tšebeliso e nepahetseng ea Mechini ea Jaw Crusher

Mechini e silafatsang mehlahare e ipabolalits'ebetsong tse fapaneng ka lebaka la ho ikamahanya le maemo le bokhoni ba tsona. Ho utloisisa mefuta ea lisebelisoa tseo ba li sebelisang, likopo tsa bona tse ikhethileng indastering, le ho hlaka le ho tenyetseha ha bona ho ka thusa basebelisi ho etsa liqeto tse nepahetseng.

Mefuta ea Lisebelisoa tse Sebelitsoeng

Li-crushers tsa mohlahare li sebetsana le mefuta e mengata ea lisebelisoa, li etsa hore li tšoanele liindasteri tse fapaneng. Ho ea ka litlaleho tsa indasteri, lisebelisoa tse sebelisoang hangata li kenyelletsa:

| Lekala | Lisebelisoa tse Tloaelehileng tse Sebelitsoeng | Karolo ea mmaraka (%) |

|---|---|---|

| Morafo | Ore ea tšepe, mashala, koporo, thepa e nang le khauta | 68 |

| Kaho | Aggregates, lehlohlojane, litšila tse senyang | 22 |

Thets'ebetso ea li-crushers tsa mohlaharee fapana ho ipapisitsoe le boima ba thepa. Ka mohlala, lisebelisoa tse thata tse kang granite (Mohs hardness of 7) li hloka matla a mangata ho senya. Sena se lebisa ho phallo e tlase ha e bapisoa le lisebelisoa tse bonolo, tse kang konkreite (Mohs hardness of 5). Mona ke lintlha tse ling mabapi le boima ba lintho tse bonahalang:

- Lisebelisoa tse thata li hloka matla a mangata, e leng se etsang hore ho be le matla a fokolang.

- Ho pshatla granite ho ka fana ka tlhahiso ea hoo e ka bangLithane tse 10 ka hora (TPH).

- Lisebelisoa tse bonolo joalo ka konkreite li ka fihlella ho pota 50 TPH tlasa maemo a ts'oanang.

- Ho utloisisa sekala sa boima ba Mohs ho bohlokoa bakeng sa ho hakanya tšebetso le ho ntlafatsa maemo a ts'ebetso.

Lisebelisoa tse Ikemetseng tsa Indasteri

Mechini ea crusher ea mehlahare e sebeletsa liindasteri tse fapaneng, e 'ngoe le e 'ngoe e na le litlhoko tse ikhethang. Mona ke tsenalisebelisoa tsa mantlha:

- Indasteri ea Merafo: Li-crushers tsa mohlahare li pshatla majoe a maholo likotoana tse nyane, li lokisa lirafshoa tse kang tšepe, koporo, khauta le silevera.

- Indasteri ea ho Cheka Likwari: Ba pshatla majoe, konkreite le sekontiri bakeng sa merero ea kaho.

- Indasteri ea Kaho: Hangata e sebelisetsoa ho tsosolosa lisebelisoa tse kang konkreite le asphalt bakeng sa kaho ea litsela le merero ea kaho.

- Indasteri ea ho Recycling: E sebetsa hantle ka ho pshatla mefuta e fapaneng ea lisebelisoa, ho kenyeletsoa likhalase, polasetiki, tšepe le pampiri, haholo-holo ha ho sebelisoa lintho tse thata joalo ka litšila tsa elektroniki.

Liindasteri tse fapaneng li na le tse ikhethanglitlhoko tsa kopo. Tafole e latelang e akaretsa litlhoko tsena:

| Indasteri | Litlhoko tsa Kopo | Mesebetsi ea Bohlokoa |

|---|---|---|

| Morafo | Ho silakanya ha lintho tse thata le tse senyang, ho fokotsa boholo ba ore bakeng sa ho sebetsa | Ho ntšoa ha tšepe, ho sebetsana le thepa, tlhahiso e kopaneng, sampole ea jeoloji, polokeho le tlhahiso |

| Kaho | Ho pshatla konkreite, litene, majoe le lisebelisoa tse ling bakeng sa ntlafatso ea meaho | Ho heletsoa, kaho ea litsela, mosebetsi oa motheo, ho tsosolosa, ho hloekisa libaka, ho sebetsana le thepa |

| Recycling | Ho sila le ho fokotsa lisebelisoa tse kang konkreite le asphalt hore e be mefuta e ka sebelisoang hape | Mesebetsi ea ho tsosolosa, ho fokotsa litšila, ho boloka mehloli |

Scalability le Flexibility

Scalability le ho feto-fetoha ha maemo ke likarolo tsa bohlokoa tsa mochini o senyang mehlahare. Li ikamahanya le boholo bo fapaneng ba ts'ebetso le litlhoko tsa projeke. Li-crusher tsa mehlahare tse mahareng hangata li na le bokhoni ho tloha ho200 ho isa ho 500 tph, ho li etsa hore li tšoanelehe bakeng sa lits'ebetso tse kang ho chekoa le ho li sebelisa hape. Li-crushers tse kholo tsa mohlahare li ka feta 500 tph, 'me mefuta e meng e sebetsa ho fihla ho 1,500 tph, e loketseng lisebelisoa tse boima. Lintlha tse susumetsang bokhoni li kenyelletsa:

- Boholo ba ho senya

- Boholo ba fepa

- Litšobotsi tsa lintho tse bonahalang

- Litekanyetso tsa ts'ebetso

- Lebelo la ts'ebetso

- Mongobo oa lintho tse bonahalang

Likarolo tsa ho feto-fetoha ha maemo li ntlafatsa ho ikamahanya le maemo ho fetola litlhoko tsa projeke. Mohlala, ho buloa ho ka fetolehang ho lumella taolo holim'a boholo ba tlhahiso. Bokhoni bona bo thusa ho hlahisa likaroloana tse mahoashe le granularity e ntle haholoanyane. Mona ke kakaretso ea likarolo tsa ho feto-fetoha ha maemo:

| Sebopeho | Tlhaloso |

|---|---|

| Ho Fetolana ho Boholo ba Poelo | Setlhophiso sa lehlakore le koetsoeng (CSS) se ka fetoloa ho fetola boholo ba tlhahiso bakeng sa litlhoko tse fapaneng tse sithabetsang. |

| Ho feto-fetoha ha maemo | E loketse mesebetsi ho tloha ho ho pshatla mafika a maholo ho isa ho ho hlahisa lejoe le pshatlehileng hantle. |

Li-crushers tsa mehlahare li tsebahala ka katleho ea tsona le ho ikamahanya le maemo, e leng se etsang hore e be khetho e ratoang lits'ebetsong tse fapaneng tsa indasteri ka lebaka la bokhoni ba tsona ba ho fihlela litlhoko tse fetohang tsa morero.

Litlhokomelo tsa Tlhokomelo bakeng sa Mechini ea Jaw Crusher

Ho boloka metjhini e silafatsang mehlaharee bohlokoa ho netefatsa bophelo ba bona bo bolelele le ts'ebetso ea bona. Mekhoa e nepahetseng ea tlhokomelo e ka fokotsa haholo nako ea ho theoha le ho ntlafatsa tlhahiso.

Boiketlo ba Paballo

Tlhokomelo e bonolo e ama ka kotloloho litšenyehelo tsohle tsa beng ba li-crushers tsa mehlahare. Tlhokomelo ea kamehla e thusa ho thibela litokiso tse bitsang chelete e ngata le ho boloka mechine e sebetsa hantle. Hangata basebelisi ba tobana le mathata a kang:

- Lerata le sa tloaelehang nakong ea ts'ebetso, e bontshang dikarolo tse hlephileng kapa dikarolo tse tsofetseng.

- Ho fokotsa matla a ho senya, ho lebisang ho fokotseng tlhahiso.

- Ho thothomela ho feteletseng ho amang botsitso le ho baka ho senyeha ha likarolo pele ho nako.

Mekhoa e metle ea tlhokomelo e ka fokotsa litaba tsena. Basebelisi ba lokela ho etelletsa pele phihlello e bonolo ea likarolo tsa kahare. Liphuputso li bontša seoho fihlela ho 40% ea nako ea tlhokomeloe ka sebelisoa ho qhaqha le ho kopanya hape. Ho nolofatsa mokhoa ona ho ka etsa hore ho boloke nako e ngata.

Ho fumaneha ha Likarolo tse Sebeletsang

Theho fumaneha ha likarolo tse lingke ntlha e 'ngoe ea bohlokoa ea ho boloka li-crushers tsa mehlahare. Ho fihlella kapele ho likarolo tse ncha ho netefatsa nako e fokolang. Kakaretso ea likarolo tse ling tse fumanehang bakeng sa lihlahisoa tse kholo ke tsena:

| Brand | Ho fumaneha ha Likarolo tse Sebeletsang |

|---|---|

| Terex | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

| Sandvik | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

| Powerscreen | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

| Mofetoheli | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

| Extec | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

| Finlay | Karolo e ncha ea Jaw Crusher Wear e fumaneha |

Lihlahisoa tse kang GTEK Mining li boetse li fana ka likarolo tse hahiloeng bakeng sa bophelo bo bolelele ba tšebeletso, ho netefatsa hore basebetsi ba ka fumana likarolo tsa ho apara letsatsi le leng le le leng kapa ho senyeha ho sa lebelloang.

Litšenyehelo tsa Tlhokomelo

Litšenyehelo tsa tlhokomelo li ka fapana haholoho pholletsa le bahlahisi le lits'ebetso tse fapaneng. Mona ke papiso ea litšenyehelo tse tloaelehileng tsa tlhokomelo ho latela mofuta oa kopo:

| Mofuta oa Kopo | Mefuta e tloaelehileng ea Theko ea Theko | Litšenyehelo tsa Tlhokomelo |

|---|---|---|

| Merafo le Boima-Boima | $$$$ | E mahareng ho isa Hodimo |

| Aggregate Production | $$$ | E itekanetseng |

| Kaho e Nyenyane | $$ | Tlase |

Litsenyehelo tsa selemo le selemo tsa tlhokomelo ea li-crushers tsa mohlahare hangata li tloha ho $15,000 ho ea ho $25,000 unit ka 'ngoe. Litšenyehelo tsena li itšetlehile ka matla a tšebeliso le maemo a tikoloho. Ka ho utloisisa lintlha tsena, basebelisi ba ka etsa liqeto tse nang le tsebo tse ntlafatsang ts'ebetso le ts'epahalo ea mechini ea bona ea "crusher" ea mehlahare.

Tšehetso ea ka mor'a ho rekisa bakeng sa Mechini ea Jaw Crusher

Ka mor'a ho reka sesepa sa mohlahare,tšehetso ka mor'a thekiso e ba ea bohlokoabakeng sa ho holisa boleng ba eona. Lisebelisoa tse matla tsa ts'ehetso li ka ntlafatsa haholo ts'ebetso ea ts'ebetso le ho netefatsa khotsofalo ea nako e telele.

Warranty le Litumellano tsa Tšebeletso

Baetsi ba li-crushers tsa mohlahare ba atisa ho fana ka tsonatiisetso e matla le litumellano tsa litšebeletso. Litumellano tsena li fana ka khotso ea kelello le ho sireletsa matsete. Kakaretso ea mantsoe a tloaelehileng a tiisetso ke ena:

| Karolo | Lintlha |

|---|---|

| Warranty Nako | Lilemo tse peli ho tloha ka letsatsi la ts'ebetso ea pele. |

| Kakaretso | Lisebelisoa tse ncha tsa ho nchafatsa le ho lokisoa haeba e se ts'enyehelo e entsoeng ke motho. |

| Tšehetso ea tekheniki | Ho fanoe ka tšehetso ea mahala ea tekheniki ea bophelo bohle. |

| Nako ea Karabelo | Litaba tsa bareki li rarollotsoe nakong ea lihora tse 24, li rarollotsoe nakong ea lihora tse 72. |

Litiisetso tse joalo li bontša tšepo ea bahlahisi lihlahisoa tsa bona. Ba boetse ba etsa bonnete ba hore bareki ba fumana thuso ka nako ha ho hlokahala.

Ho fumaneha ha Tšehetso ea Bareki

Ho fumaneha ha tšehetso ea bareki ke tšobotsi e 'ngoe ea bohlokoa. Baetsi ba holimo ba fana ka lihlopha tsa tšehetso tse inehetseng ho thusa basebelisi. Likarabo tse potlakileng lipotsong li ka fokotsa nako le ho ntlafatsa tlhahiso. Likhamphani tse ngata li fana ka liteishene tse ngata bakeng sa ts'ehetso, ho kenyeletsoa mohala, lengolo-tsoibila le moqoqo o phelang. Ho fihlella hona ho netefatsa hore basebelisi ba khona ho rarolla mathata ka nepo, ho ba lumella ho tsepamisa maikutlo mesebetsing ea bona ea mantlha.

Koetliso le Lisebelisoa

Mananeo a koetliso a fanoang ke bahlahisi a phetha karolo ea bohlokoa tšebelisong e atlehang ea mechine e pshatlang mohlahareng.Basebetsi ba koetlisitsoeng hantle ba ka arabela liphephetso ka katleho. Mona ke melemo ea mantlha ea mananeo ana a koetliso:

- Koetliso ea basebetsi e bohlokoa bakeng sa tšebeliso e sireletsehileng ea lisebelisoa.

- Lithuto tsa ho hlasimolla khafetsa li boloka basebetsi ba nchafalitsoe ka theknoloji le mekhoa ea polokeho.

- Koetliso e etselitsoe mochini o khethehileng le sebaka sa mosebetsi.

Mananeo ana a fokotsa liphoso le ho ntlafatsa polokeho ea sebaka sa mosebetsi. Li boetse li ntlafatsa bophelo bo bolelele ba lisebelisoa ka ho netefatsa tšebeliso e nepahetseng. Basebelisi ba ithuta ho rarolla mathata a mantlha sebakeng sa marang-rang, ba fumana maikutlo hanghang a thusang ho ntlafatsa ts'ebetso ea mochini. Ho tsetela thupelong ha ho phahamise tlhahiso feela empa hape ho khothalletsa moetlo oa polokeho le katleho.

Ka bokhutšoanyane, ho khetha mechine e nepahetseng ea ho senya mohlahare ho kenyelletsa ho utloisisa likarolo tse 'maloa tsa bohlokoa. Lintlha tsa bohlokoa li kenyelletsamatla a ho senya, boholo ba phepelo, ho feto-fetoha ha tlhahiso, le ho nkeha habonolo. Likarolo tsena li ama haholo ts'ebetso ea ts'ebetso le tlhahiso ka kakaretso.

Nahana ka lintlha tsena ha u reka:

- Bokhoni ba ho hatakela: Etsa bonnete ba hore e lumellana le lipakane tsa tlhahiso.

- Fepa Boholo: Bapisa mochini le boholo ba thepa ea hau.

- Ho fetoha: Batla litlhophiso tse lumellang ho laola boholo ba tlhahiso.

- Portability: Khetha ho latela litlhoko tsa sebaka le boiketlo.

Ka ho beha likarolo tsena pele, basebelisi ba ka etsa liqeto tse nang le tsebo tse khotsofatsang litlhoko tsa bona tse khethehileng.Lithuto tse atlehileng, joalo ka projeke ea merafo ea Afrika Boroa le polante ea granite ea Uganda, li bonts'a melemo ea ho khetha mechini ho latela litekanyetso tsena.

LBH

Mosebetsi oa mantlha oa mochini o pshatlang mohlahare ke ofe?

Mechini e pshatlang mehlahare e pshatla majoe a maholo hore e be likotoana tse nyane, tse laolehang. Ba ipabola ka ho pshatla thepa e thata e kang granite, limestone, le ores, e leng se etsang hore e be tsa bohlokoa indastering ea merafo le ea kaho.

Nka khetha setlolo sa mohlahare se nepahetseng joang bakeng sa litlhoko tsa ka?

Nahana ka lintlha tse kang ho senya matla, boholo ba lijo, le mofuta oa thepa. Lekola litlhoko tse ikhethileng tsa ts'ebeliso 'me u khethe mohlala o tsamaellanang le lipheo tsa hau tsa tlhahiso le maemo a ts'ebetso.

Ke mekhoa efe ea tlhokomelo eo ke lokelang ho e latela bakeng sa li-crushers tsa mohlahare?

Kamehla hlahloba likarolo tsa ho apara, etsa bonnete ba hore li tlotsa ka mokhoa o nepahetseng, 'me u hloekise mochine ho thibela ho bokellana ha litšila. Etsa moralo oa tlhokomelo ea kamehla ho rarolla mathata a ka 'nang a hlaha pele a eketseha.

Na li-spare parts li fumaneha habonolo bakeng sa li-crushers tsa mehlahare?

E, bahlahisi ba bangata ba nang le botumo bo botle ba fana ka mefuta e mengata ea likarolo tse ling. Ho fihlella ka potlako ho likarolo tsena ho fokotsa nako ea ho theoha 'me ho netefatsa ts'ebetso e tsitsitseng, ho matlafatsa tlhahiso ka kakaretso.

Nka ntlafatsa ts'ebeliso e ntle ea matla ea mochini oa ka oa mohlahare joang?

Ntlafatsa liparamente tsa ts'ebetso, joalo ka ho lokisa lebelo la ho senya le sekhahla sa phepelo. Tlhokomelo ea kamehla le ho sebelisa mehlala e sebetsang hantle haholo e ka fokotsa haholo tšebeliso ea matla le litšenyehelo tsa ts'ebetso.

Nako ea poso: Oct-15-2025