Litlhahlobo tsa kamehla tsalikarolo tse silafetseng, ho kenyeletsadikarolo tsa mohlaharelecone crusher likarolo tse ling, phetha karolo ea bohlokoa ho netefatsa ts'ebetso e nepahetseng le ho tšepahala. Liphuputso li bontša seotlhokomelo e sa lekaneng ea lisebelisoajoalo kagyratory crushere ka lebisa ho hloleheng pele ho nako, 'me karolo e kholo ea litaba e saloa morao ka lebaka la khaello ea tlhahlobo.Likarolo tsa bohlokoa tse lokelang ho hlahlojoa li kenyelletsa likarolo tsa matla a hydraulic, mocheso oa oli, le maemo a ho jara. Ho beha lintlha tsena leihlo khafetsa ha ho thibele nako ea ho theoha e theko e boima feela empa hape ho ntlafatsa katleho ea lisebelisoa ka kakaretso. Mohlala,liphetoho tsa liner tse nakongka li-crushers li ka thibela tahlehelo ea ts'ebetso, qetellong li lelefatsa bophelo ba ts'ebeletso ea likarolo tsa bohlokoa, haholo-holo tse entsoeng katšepe e phahameng ea manganese.

Lintlha tsa bohlokoa

- Ho hlahlojoa khafetsa ha likarolo tsa crusher ho bohlokoa bakeng sa ts'ebetso e nepahetseng le polokeho. Tsepamisa maikutlo holim'a likarolo tsa ho roala, lintlha tsa lubrication, ho tsamaisana, likarolo tsa motlakase, lebotshepehi ba sebopeho.

- Etsa kemiso e tiileng ea tlhokomelo. Etsa tlhahlobo ea letsatsi le letsatsi bakeng sa liboutu tse hlephileng le mafura, tlhahlobo ea pono ea beke le beke, le tlhahlobo ea khoeli le khoeli ea mochini.

- Lekola matšoao a ho felloa ke matla, joalo ka ho thothomela ho feteletseng, lerata le mapetsong a bonahalang. Ho lemoha kapele ho thibela ho hloleha ho sa lebelloang le ho fokotsa nako e theko e boima.

- Sebelisalisebelisoa tsa boleng bo holimo bakeng sa likarolo tsa ho roalaho matlafatsa nako e telele. Ho hlahlojoa khafetsa ho thusa ho tseba ha ho hlokahala hore ho nkeloe sebaka, ho lelefatsa bophelo ba ts'ebeletso ea likarolo tsa bohlokoa.

- Beha pele polokeho ea motlakase nakong ea tlhahlobo. Hlahloba likhokahano bakeng sa ts'ireletso 'me u netefatse hore lithapo tsa fatše li tiile ho thibela likotsi tsa mollo le ho netefatsa ts'ebetso e sireletsehileng.

Apara Likarolo

Likarolo tsa ho roala ke likarolo tsa bohlokoaka har'a sephahla sefe kapa sefe. Ba utloa bohloko bo boholo nakong ea ts'ebetso. Ho hlahlojoa khafetsa ha likarolo tsena ho thusa ho boloka ts'ebetso e nepahetseng le ho thibela ho hloleha ho sa lebelloang. Likarolo tsa bohlokoa tsa ho roala li kenyelletsapoleiti ea mohlahare e tsitsitseng, poleiti ea mohlahare e tsamaeang, le li-cheek plates. E 'ngoe le e' ngoe ea likarolo tsena e phetha karolo ea bohlokoa ts'ebetsong ea ho senya.

Mona ke kakaretso ea mefuta ea mantlha ea likarolo tsa liaparo tse fumanehang ka har'a li-crusher:

| Mofuta oa Karolo ea Ho Apara | Tlhaloso |

|---|---|

| Likarolo tsa ho roala mohlahare | E kenyelletsa poleiti ea mohlahare e tsitsitseng, poleiti ea mohlahare e tsamaeang, le li-cheek plates. |

| Letlapa le tsitsitseng la mohlahare | E kenya 'meleng oa sefate sa mohlahare; e fumaneha ka meralo e le 'ngoe le likarolo tse peli. |

| Letlapa la mohlahare le tsamaeang | E kenya ka har'a mehlahare e tsamaeang; e fumaneha hape ka meralo ea karolo e le 'ngoe le likarolo tse peli. |

| Lipoleiti tsa marameng | E sireletsa lehlakore la 'mele oa sefate sa mohlahare ho senya lejoe le pshatlehileng. |

Ho hlahlojoa khafetsa ha likarolo tsa sehlahla sa mohlaharee tlameha ho etsahala lihora tse ling le tse ling tse 250 tsa ts'ebetso. Ho bohlokoa ho latela kemiso e tiileng ea tlhokomelo ea letsatsi le letsatsi, beke le khoeli le khoeli le khoeli. Basebelisi ba lokela ho batlamatšoao a ho tsofala hofeta tekanyo, joalo ka:

- Ho thothomela kapa lerata le feteletseng

- Mapetso a bonahalang kapa tshenyo ya sebopeho

- Ho fokotsa lipoleiti le li-liner

- Mekhoa e sa tšoaneng ea ho apara

- Sehlahisoa se fokotsehileng kapa se seholo ho feta tekano

- Ho koaleha kgafetsa kapa jeme ya dintho

- Tšebeliso e eketsehileng ea matla

- Ho ba le mathata a ho futhumatsa kapa ho tlotsa

Nako ea bophelo ea likarolo tsa manganese e ka fapana haholo, ho tloha holibeke tse tšeletseng ho isa ho lilemo tse tšeletseng, ho itšetlehile ka lefika le sebetsoang. Ho khethalisebelisoa tsa boleng bo holimoke ea bohlokoa bakeng sa likarolo tse senyehileng hore li mamelle maemo a thata. Lisebelisuoa tsa Premium li ntlafatsa khanyetso ho abrasion, tšusumetso le ho khathala, tse lebisang bophelong bo bolelele ba ts'ebeletso. Tlhahlobo ea kamehla e thusa ho tseba mekhoa ea ho apara le ho fumana hore na ho hlokahala ho nkeloa sebaka neng.

Ho kenya tshebetsongkhetho ea boleng le tlhahlobo ea kamehlae matlafatsa tshebetso le ho tšoarella. Tlhokomelo e nepahetseng le ts'ebetso e ntlafalitsoeng ke ea bohlokoa bakeng sa ho boloka litšenyehelo. Koetliso ea opereishene e boetse e tlatsetsa katlehong e akaretsang ea likarolo tsa ho roala.

Lintlha tsa Lubrication

Lubrication e nepahetseng e bohlokoa bakeng sa ts'ebetso e ntle ea likarolo tsa crusher. Ho hlahloba khafetsa lintlha tsa lubrication ho thibela ho hloleha ha mochini mme ho lelefatsa nako ea bophelo ea likarolo tsa bohlokoa. Sebaka se seng le se seng sa lubrication se na le litlhoko tse ikhethileng tseo basebelisi ba lokelang ho li latela ho boloka ts'ebetso e nepahetseng.

Mona ke lintlha tse ling tsa bohlokoa tsa lubrication le tsonamafura a khothalletsoang:

| Sebaka sa Lubrication | Lubricant e khothalelitsoeng | Lintlha |

|---|---|---|

| Eccentric Shaft Bearings | Jet-Lube Jet-Plex EP™ Grease | E hloka grease e tsitsitseng ka mochini bakeng sa ho kenya ts'abo le ho sisinyeha. |

| Pitman Bearings | Jet-Lube Jet-Plex EP™ Grease | E imetsoe haholo; grease lokela ho boloka botsitso. |

| Mokotla o Matla oa Suspension | Mafura a nakoana | Lubricated ntle le ho khutla ha oli; e hloka kopo ea kamehla. |

| Hlakola Elbow ea Plate | Oli e teteaneng | E hloka lubrication lihora tse ling le tse ling tse 3-4; e fapaneng le lintlha tse ling. |

| Mehlahare e Menyane ea Mofuta oa ho Beha | Komiki ea oli le oli e tlotsang | E ka sebelisoa hang ka mor'a metsotso e 30-40. |

Basebelisi ba lokela ho hlophisatšebeletso ea letsatsi le letsatsi le lubrication. Ba tlameha ho hlahloba lintlha tsa moetsi bakeng sa sesebelisoa ka seng. Ho kenya ts'ebetsong mekhoa ea ho laola tšilafalo ho bohlokoa hape. Ho hlokomoloha litlhahlobo tsena ho ka lebisa hoditlamorao tse matla. Mohlala,ho hloleha ho jara pele ho nakoe ka hlaha ka lebaka la ho se be le setlolo se lekaneng. Ho feta moo, litaba tse kang li-hemo-off-off li ka lumella lerōle ka phaposing ea oli, e leng se lebisang mathateng a mang.

Ho bohlokoa ho sebelisa mofuta o nepahetseng oa mafura. Basebelisi ba lokela ho nahana ka maemo a tikoloho joalo ka mongobo le mocheso. Ho khetha litlolo tse nang le metsi a fokolang a ho hlatsoa le ho thibela ho bola ho hoholo ho bohlokoa bakeng sa libaka tse mongobo. Litlolo tse phahameng tsa viscosity li sebetsa hantle bakeng sa lits'ebetso tsa lebelo le tlase, tse nang le mojaro o phahameng.

Licheke tsa ho Ikamahanya

Licheke tsa ho tsamaisana li bohlokoa bakeng sa ho boloka ts'ebetso le nako e telele ea likarolo tsa crusher. Ho tsamaisana hantle ho tiisa ts'ebetso e bonolo le ho fokotsa ho roala ha likarolo. Ho hlahlojoa khafetsa ho ka thibela ho theoha ho theko e boima le ho ntlafatsa ts'ebetso ka kakaretso. Mona ke litlhahlobo tse ling tsa bohlokoa tseo u ka li nahanang:

- Ho Lokisetsa lebanta: Ho tsamaisana hantle ha lebanta ho bohlokoa bakeng sa ts'ebetso e nepahetseng. E netefatsa phallo e boreleli ea thepa le ho fokotsa nako ea ho phomola.

- Ho leka-lekanya Crusher: Ho boloka boemo ba crusher ho bohlokoa bakeng sa ho latela lebanta le nepahetseng. Sena ke sa bohlokoa ka ho khetheha ka mor'a ho tsamaisa thepa.

- Liphetoho tsa ho Idler: Haeba lebanta le tsoa tseleng, ho hlokahala hore ho lokisoe batho ba sa sebetseng hantle. Ho sisinyeha ho itseng ho ka lokisa litaba tsa ho tsamaisana.

- Li-extensions tsa ho nka: Ho atolosoa ho lekanang kapa ho khutlisa ho nka-ups ho bohlokoa bakeng sa ho boloka tsitsipano ea lebanta. Sena se thusa ho thibela ho thella le ho senyeha.

- Liphetoho tse Ncha tsa Mabanta: Mabanta a macha a ka hloka liphetoho tse ngata ha a ntse a otlolla le ho lula sebakeng.

Ho se tsamaisane hantle ho ka lebisa liphellong tse 'maloa tse mpe. Tafole e ka tlase e akaretsa litlamorao tse ka bang teng tsa ho se tsamaisane hantle tlhahisong ea tlhahiso le nako e telele ea lisebelisoa:

| Sephetho | Tlhaloso |

|---|---|

| Accelerated Wear and Tear | Ho se lumellane ho baka matla a sa tloaelehang a lebisang ho khohlano e eketsehileng le ho kopana pakeng tsa likarolo. Sena se fella ka ho senyeha ka potlako le tlhokomelo khafetsa. |

| Ho se sebetse hantle ha Matla | Mechini e sa tsamaeeng hantle e hloka matla a mangata ho sebetsa. Sena se lebisa litšenyehelong tse phahameng tsa ts'ebetso le ho fokotsa katleho tlhahisong ea tlhahiso. |

| Nako ea Bophelo e Fokotsoe | Ho pepesehela ho thothomela ho feteletseng ho khutsufatsa nako ea bophelo ea mochini. Sena se eketsa menyetla ea ho senyeha le ho fokotseha ha nako. |

| Likotsi Tsa Tšireletseho | Maemo a phahameng a ho sisinyeha a ka lebisa ho hloleheng ho hoholo. Sena se beha likotsi ho basebetsi le lits'ebeletso tse potolohileng. |

| Mathata a ho Laola Boleng | Liphetho tse sa tsitsang tse tsoang ho lisebelisoa tse sa lumellaneng li ka lebisa lits'ebetsong tse sa tsitsang. Sena se ama boleng ba tlhahiso ka kakaretso. |

Ho etsa lipatlisiso tsa ho tsamaisana hantle, basebelisi ba ka sebelisa lisebelisoa le mekhoa e fapaneng. Tafole e latelang e bonts'a mefuta ea lisebelisoa tse tloaelehileng le bohlokoa ba tsona tlhahlobong ea ho tsamaisana:

| Mofuta oa Thepa | Bohlokoa ba Licheke tsa ho Loana |

|---|---|

| Li-turbine (khase, moea, mouoane) | E ka ba le liphetoho tse kholo tsa mocheso tse bakang motsamao oa liphaephe le metheo. |

| Li-Chillers tsa Sehatsetsing | Likarolo tse tsamaellanang li kotsing ea ho sisinyeha ho sa lebelloang ka lebaka la ho holisoa ha compressor. |

| Metsi a Chelisitsoeng, Metsi a Condenser, le Lipompo tsa Metsi a Fepang | Liphetoho tsa mocheso li ka baka ho sisinyeha ha mochini, haholo haeba li-base li se boholo bo lekaneng. |

| Extruders | Lithempereichara tse kholo li ka lebisa motsamaong oa mochini ha nako e ntse e ea. |

| Lihlahisoa tsa Hammer, Crushers | Sebopeho sa mosebetsi se ka baka motsamao o sa rereloang, leha o koetsoe ka bolt. |

| Mechini e meng | E fana ka melemo e kang ho hlahloba likhokahano le litiiso, le ho ikoetlisa ka lisebelisoa tsa ho tsamaisana. |

Ho hlahlojoa khafetsa ho bohlokoa bakeng sa ho boloka ts'ebetso le polokeho ea likarolo tsa crusher. Ho kenya tšebetsong kemiso e tloaelehileng ea tlhahlobo ho ka ntlafatsa haholo ts'ebetso ea lisebelisoa le bophelo bo bolelele.

Lisebelisoa tsa Motlakase

Likarolo tsa motlakase li bapala karolo ea bohlokoaseabo ts'ebetsong ea li-crushers. Ho hlahlojoa khafetsa ha likarolo tsena ho thusa ho thibela ho hloleha le ho netefatsa polokeho. Basebelisi ba lokela ho tsepamisa maikutlo libakeng tse 'maloa tsa bohlokoa nakong ea tlhahlobo ea bona.

Mathata a tloaelehileng a motlakasee fumanoang nakong ea tlhahlobo ea crusher e kenyelletsa:

- Mathata a phepelo ea motlakase, joalo ka motlakase o sa tsitsang kapa ho hloka matla.

- Li-switches tsa ho qala tse fosahetseng kapa mathata ka phanele ea taolo.

- Li-fuse kapa li-circuits tse khoptjoang.

- Li-interlock tse kentsoeng ts'ireletso kapa litopo tsa tšohanyetso.

- Lithapo kapa likhokahano tse fosahetseng.

- Ho hloleha ha li-sensor kapa liphoso tsa puisano lits'ebetsong tse ikemetseng.

- Litšitiso tsa software kapa firmware ea khale.

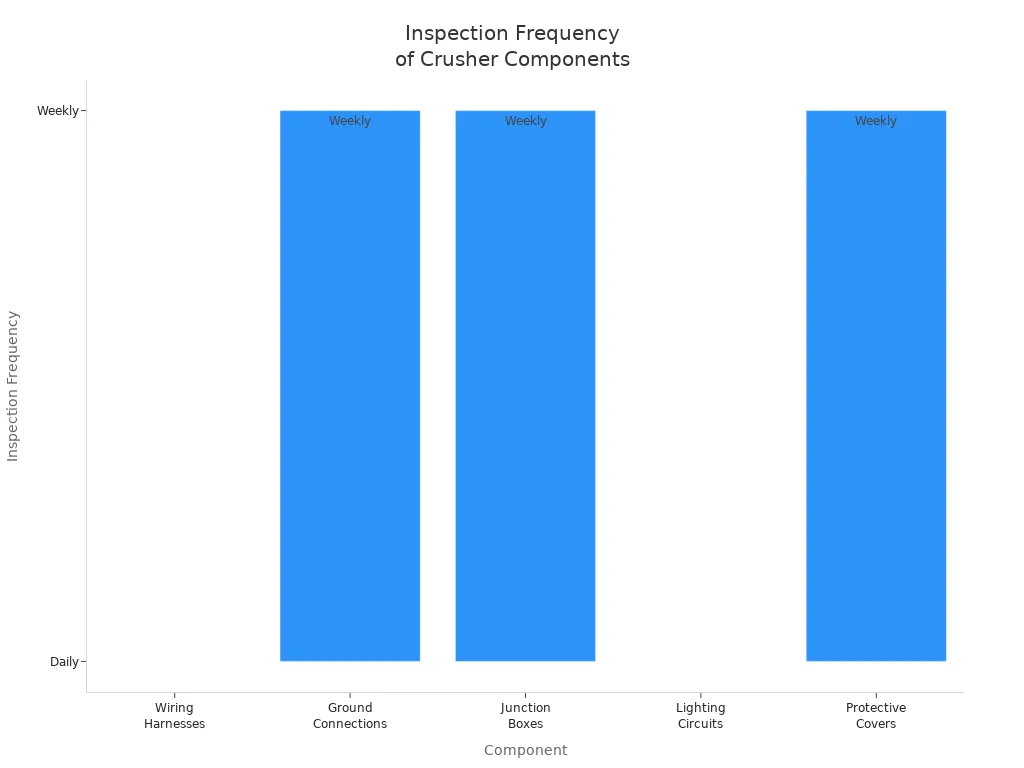

Ho latela melaoana ea polokeho, basebelisi ba lokelahlahloba likarolo tsa motlakase khafetsa. Lethathamo le latelang le bontšae khothaletsoang mefuta le maqhubu a tlhahlobo:

| Karolo | Mofuta oa Tlhahlobo | Khafetsa |

|---|---|---|

| Lithapo tsa likhoele | Pono/Ka mmele | Letsatsi le letsatsi |

| Likamano tsa fatše | Teko ea Khanyetso | Beke le beke |

| Mabokose a Junction | Tlhahlobo ea Mongobo | Beke le beke |

| Lipotoloho tsa Lebone | Teko ea Mosebetsi | Letsatsi le letsatsi |

| Likoahelo Tse Sireletsang | Botšepehi Hlahloba | Beke le beke |

Ho bohlokoa ho hlahloba likhoele tsa motlakase le likhokahano. Basebelisi ba tlameha ho:

- Netefatsa hore likhokelo tsa motlakase li bolokehilepele o qala thepa efe kapa efe.

- Kamehla hlahloba likhokahano tse hlephileng kapa lithapo tse robehilengho qoba dikotsi tsa mollo.

- Netefatsa hore lithapo tsa fatše, li-plug tsa motor, le likhokello tsa lithapo tsa motlakase li bolokehile pele lisebelisoa li sebetsa.

Ho hlokomoloha litlhahlobo tsena ho ka baka likotsi tse tebileng.Lisebelisoa tsa motlakase tse fosahetseng li ka baka mollo, ho etsa hore ho be bohlokoa ho ba le matla a ho tima mollo sebakeng sa marang-rang. Tlhahlobo ea kamehla ea pono e thusa ho netefatsa polokeho le tšehetso e nepahetseng ea cable. Ho feta moo, likamore tsa ho kenya motlakase li tlameha ho lula li omme ebile li se na lisebelisoa tse tukang.

Ka ho beha pele tlhahlobo ea likarolo tsa motlakase, basebelisi ba ka ntlafatsa polokeho le katleho ea ts'ebetso ea bona ea li-crusher.

Botšepehi ba Sebopeho

Ho bolokabotšepehi ba sebopeho sa li-crushere bohlokoa bakeng sa ts'ebetso e bolokehileng le e sebetsang hantle. Litlhahlobo tsa kamehla li thusa ho tseba mathata a ka bang teng pele a ka fetoha mathata a maholo. Basebelisi ba lokela ho tsepamisa maikutlo ho licheke tse 'maloa tsa bohlokoa ho netefatsa boleng ba sebopeho sa lisebelisoa tsa bona.

Ke tsenacheke ea bohlokoa ea sebopeho bakeng sa li-crushers:

| Lekola Mofuta | Tlhaloso |

|---|---|

| Liteko tsa Bolt Torque | Kemiso ea ho lekola le ho ts'oara bocha liboutu tsa bohlokoa tsa sebopeho li bohlokoa. |

| Tlhahlobo ea Crack | Litlhahlobo tsa nako le nako bakeng sa mapetsong a moriri, haholo-holo libakeng tsa khatello ea maikutlo, li bohlokoa. |

| Lubrication | Ho tlotsa ka mokhoa o nepahetseng ka mofuta o nepahetseng le kereiti ho thibela ho chesa le ho roala. |

| Tlhahlobo ea Vibration | Ho hlahlojoa khafetsa ho ka lemoha matšoao a pele a ho hloleha pele ho lebisa ho senyeheng ha koluoa. |

Lintlha tsa tikoloho tse kang ho thothomela le mocheso li ka ama haholo sebopeho sa likarolo tsa crusher.Ho fapana ha mocheso le meroalo e ka ntlerarahana matla a sebopeho, a ka lebisang ho hloleheng. Ka mohlala, ho sebetsa ka lebelo le phahameng ho ka baka ho thothomela ho feteletseng, ho lebisang ho senyeha ha mohaho. Lubrication e nepahetseng ea hlokahala ho fokotsa likotsi tsena.

Litaba tse tloaelehileng tsa sebopeho tse hloahloa nakong ea tlhahlobokenyeletsa:

- Ho hloleha ha Mechini

- Bearings ho chesa haholo kapa ho felloa ke matla pele ho nako.

- Maqhetsoana kapa maqhetsoana a foreime ea silara.

- Ho thothomela le Lerata

- Ho thothomela ho feteletseng kapa lerata nakong ya tshebetso.

- Ho hloleha ha Sisteme ea Hydraulic

- Ho dutla kapa kgatello e sa lekaneng.

Ho hlahlojoa khafetsa le ho boloka bots'epehi ba sebopeho ho ka thibela ho theoha ho theko e boima le ho ntlafatsa nako ea bophelo ea likarolo tsa crusher. Basebelisi ba lokela ho etelletsa licheke tsena pele ho netefatsa hore ts'ebetso e bolokehile ebile e sebetsa hantle.

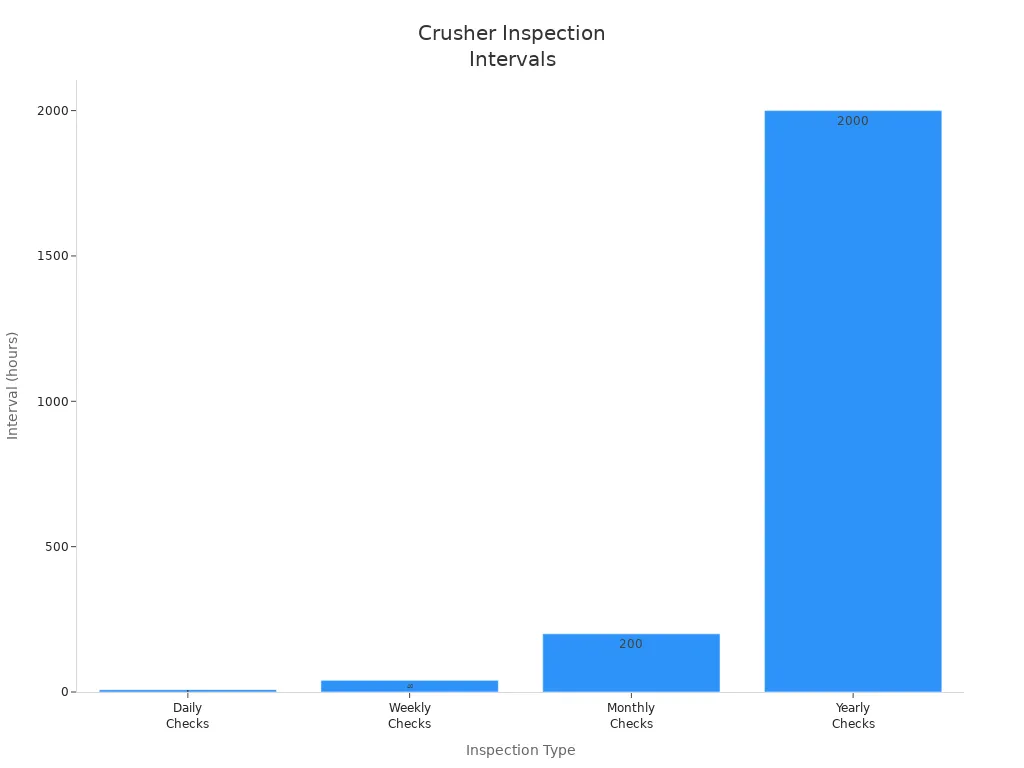

Ho hlahlojoa khafetsa ha likarolo tsa crusher ho bohlokoa bakeng sa ho boloka ts'ebetso e nepahetseng le polokeho. Lintlha tsa bohlokoa tsa tlhahlobo li kenyelletsa:

- Litlhahlobo Tsa Letsatsi le Letsatsi: Sheba liboutu tse hlephileng, hlahloba lipoleiti tsa mohlahare, 'me u tlotse likarolo tse tsamaeang.

- Tlhokomelo ea Beke le Beke: Etsa litlhahlobo tsa pono le ho hlahloba li-wear liner.

- Tlhokomelo ea Khoeli le Khoeli: Lekola litsamaiso tsa mochini le maemo a oli.

- Phetoho ea Selemo le Selemo: Harola 'me u hlahlobe likarolo tsa liaparo bakeng sa tšenyo.

Ho kenya ts'ebetsong kemiso ea tlhahlobo e tloaelehileng ho fokotsa haholo nako ea ho theoha le litšenyehelo tsa ho lokisa. Ho hlokomoloha tlhokomelo ho ka lebisa hoho senyeha ho feteletseng, ho bitsa chelete e ka bang $50,000 ka hora. Ka ho beha litlhahlobo tse tlang pele, basebelisi ba ka ntlafatsa nako e telele ea lisebelisoa le katleho ea ts'ebetso.

LBH

Ke likarolo life tsa bohlokoa ka ho fetisisa tseo u lokelang ho li hlahloba ka crusher?

Basebelisi ba lokela ho lula khafetsahlahloba likarolo tsa moaparo, lintlha tsa ho lubrication, tekano, likarolo tsa motlakase, le botšepehi ba sebopeho. Libaka tsena li ama haholo ts'ebetso ea crusher le bophelo bo bolelele.

Ke lokela ho etsa litlhahlobo hangata hakae ho crusher ea ka?

Litlhahlobo tsa letsatsi le letsatsi li bohlokoa bakeng sa liboutu tse hlephileng le mafura. Licheke tsa beke le beke li lokela ho kenyelletsa tlhahlobo ea pono, ha tlhokomelo ea khoeli le khoeli e shebane le mekhoa ea mechine. Phetoho ea selemo le selemo ke ea bohlokoa bakeng sa litlhahlobo tse phethahetseng.

Ke matšoao afe a bontšang hore likarolo tsa crusher li senyehile?

Lipontšo tsa ho roala li kenyelletsa ho thothomela ho feteletseng, lerata, mapetsong a bonahalang, lipoleiti tse fokolang tsa liaparo, le mekhoa e sa tšoaneng ea ho apara. Basebelisi ba lokela ho beha leihlo matšoao ana ho thibela ho hloleha ho sa lebelloang.

Ke hobane'ng ha lubrication e nepahetseng e le bohlokoa bakeng sa li-crushers?

Lubrication e nepahetsenge fokotsa ho ferekana le ho senyeha ha likarolo tse tsamaeang. E thibela ho futhumala ho feteletseng le ho lelefatsa nako ea bophelo ea likarolo tsa bohlokoa, ho netefatsa ts'ebetso e nepahetseng le ho fokotsa nako ea ho theoha.

Nka etsa bonnete ba polokeho ea motlakase joang nakong ea tlhahlobo?

Lekola likhokahano tsa motlakase bakeng sa ts'ireletso 'me u hlahlobe hore na ha ho na likhoele tse robehileng. Netefatsa hore lithapo tsa fatše le likhokelo tsa lithapo tsa motlakase li tiile. Ho hlahlojoa khafetsa ho thusa ho boloka polokeho le ho thibela likotsi tsa mollo.

Nako ea poso: Oct-17-2025