Tšepe ea manganese e phahamenge hlahella ka lebaka la ho hanyetsa ha eona ho sa bapisoang le ho tiea, ho etsa hore e be karolo ea bohlokoa hoLikarolo tsa Mochini oa Crusher. Boitsebiso bona bo ka mamella maemo a feteletseng, e leng se matlafatsang ts'ebetso ea ts'ebetso lefapheng la merafo. Ka ho hlakileng, lik'hamphani li boloka haholo ka tšepe e phahameng ea manganese, haholo ha e sebelisoaHamore ea tšepe ea Manganesets'ebetsong ea bona. Ka mohlala, ba ka fumana chelete ea selemo le selemo ea$ limilione tse 3.2ho pholletsa le mekhahlelo e fapaneng ea litšenyehelo. Sena se kenyelletsa liranta tse limilione tse 1.95 tse pholositsoeng ho tloha ho fokotsa nako e sa reroang, ho ntlafatsa ho fumaneha ha lisebelisoa ho tloha ho 76.5% ho ea ho 91.2%. Ntle le moo, litšenyehelo tsa tokiso ea maemo a tšohanyetso li theoha ka $680,000 selemo le selemo ka lebaka la ho lemoha mathata le tlhokomelo e reriloeng, haholoholo ha ho hiroa.Letlapa la Manganese Wearbakeng sa durability e eketsehileng. Ho feta moo, e sebetsangHo etsa tšepe ea Manganesee lumella ho etsoa ka mokhoa o nepahetseng oa likarolo, ho ntlafatsa ts'ebetso le nako e telele ea mechini libakeng tse hlokang.

Lintlha tsa bohlokoa

- Tšepe ea manganese e phahamenge fana ka khanyetso ea ho apara e sa bapisoang le ho tiea, ho etsa hore e be ea bohlokoa bakeng sa lisebelisoa tsa merafo.

- Ho sebelisa tšepe e phahameng ea manganese ho ka boloka lik'hamphani ho fihlela ho $ 3.2 milione selemo le selemo ka ho fokotsa litšenyehelo tsa nako le ho lokisa.

- Bokhoni ba ho thatafatsa mosebetsi oa tšepe e phahameng ea manganese e eketsa boima ba eona tlas'a tšusumetso, e matlafatsa ho tšoarella ha eona maemong a thata.

- Likarolo tse phahameng tsa tšepe tsa manganese li ka tšoarella nako e telele ho feta mekhoa e meng, e leng se lebisang ho theoeng ha litšenyehelo tsa tlhokomelo le tse ncha.

- Ho tsetela ka tšepe e phahameng ea manganese ho ntlafatsa ts'ebetso ea ts'ebetso,ho fokotsa nakoka ho fihla ho 30% le ho matlafatsa tlhahiso.

Lintho tse Ikhethang tsa tšepe e phahameng ea Manganese

Sebopeho le Sebopeho

Tšepe ea manganese e phahameng, eo hangata e bitsoang Hadfield steel, e na le motsoako o ikhethang oa likarolo tse tlatsetsang ho thepa ea eona e ikhethang. Motsoako o tloaelehileng oa lik'hemik'hale oa tšepe e phahameng ea manganese e sebelisoang lits'ebetsong tsa ho sila morafo o kenyelletsa:

| Kereiti | C (%) | Mn (%) | P (%) | S (%) | Kr (%) | Ke (%) |

|---|---|---|---|---|---|---|

| GX120Mn13 | 1.05-1.15 | 11-14 | Max. 0.06 | Max. 0.045 | - | - |

| GX120MnCr13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | 1.5-2,5 | - |

| GX120Mn18 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | - | - |

| GX120MnCr18-2 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | 1.5-2,5 | - |

| GX120MnNi13-3 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 3-4 |

| GX120MnMo13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 1.8-2.1 |

Likarolo tse ka sehloohong tsa tšepe e phahameng ea manganese li kenyelletsa manganese, k'habone le tšepe.Likahare tsa manganese hangata li tloha ho 11% ho isa ho 14%, ha k’habone e fapana ho ea ka maemo. Sebopeho sena se ikhethileng se etsa hore ho be le microstructure e matlafatsang ho hanyetsa le ho tiea.

Microstructure ea tšepe e phahameng ea manganese e bapala karolo ea bohlokoa ts'ebetsong ea eona. E na le sebopeho sa heterogeneous se nang le pearlite e ntle ea grained le carbides. Tokisetso enae eketsa khanyetso ea abrasion ka hoo e ka bang 16.4%. Thepa e boetse e bonts'a ho tiea le ho ts'oara ho phahameng, ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang ho hanyetsa tšusumetso le ho roala ha abrasive.

Litšobotsi tse Thatafatsang Mosebetsi

E 'ngoe ea likarolo tse hlahelletseng tsa tšepe e phahameng ea manganese ke e tsotehangbokgoni ba ho sebetsa ka thata. Ha e le tlas'a tšusumetso, thepa e ba le phetoho e eketsang boima ba eona haholo. Ketsahalo ena e etsahala ka lebaka la ho thehoa ha ε-martensite le mafahla a mechine ka har'a matrix a tšepe.

Tafole e latelang e bonts'a keketseho ea boima bo bonoang lihlopheng tse fapaneng tsa tšepe e phahameng ea manganese tlas'a maemo a tšusumetso:

| Lintho tse bonahalang | Matrix Hardness (HV) | Ho thatafala ka tlas'a lefatše (HV) | Matla a Eketseha (HV) | Mokhoa oa ho thatafatsa |

|---|---|---|---|---|

| Mn13 | 240.2 | 670.1 | 429.9 | Ho thehoa ha ε-martensite le mafahla a mechine |

| Mn13-2 | 256.6 | 638.2 | 381.6 | Ho thehoa ha ε-martensite le mafahla a mechine |

| Mn18-2 | 266.5 | 713.1 | 446.6 | Ho thehoa ha ε-martensite le mafahla a mechine |

Tšobotsi ena ea ho thatafatsa mosebetsi e lumella tšepe e phahameng ea manganese ho monya matla a bohlokoa nakong ea ts'ebetso. Ka lebaka leo, e ka mamella meroalo e nang le tšusumetso e phahameng ntle le ho robeha. Thepa ena e etsa hore e be ea bohlokoa ka ho khetheha lits'ebetsong tsa merafo, moo lisebelisoa li tobanang le maemo a feteletseng.

Ha ho bapisoa le lisebelisoa tse ling tse atisang ho sebelisoa merafo, tšepe e phahameng ea manganese e bontša bokhoni bo phahameng ba ho thatafatsa mosebetsi. Le hoja e ka 'na ea bontša matla a tlaase a lihlahisoa tlas'a ts'ebetso e leka-lekaneng kapa e fokolang, ts'ebetso ea eona tlas'a maemo a phahameng a ts'ebetso e ke keng ea lekanngoa. Motsoako ona o ikhethang oa thepa o netefatsa hore tšepe e phahameng ea manganese e lula e le khetho e ratoang indastering ea merafo.

Melemo ea Tšepe e Phahameng ea Manganese Ho Feta Lisebelisuoa Tse Ling

Litšepe tse phahameng tsa manganese li fana ka melemo e mengata ho feta lisebelisoa tse ling lits'ebetsong tsa ho sila merafo. Thepa ea eona e ikhethang e kenya letsoho homatlafatso ya nako e telelele ho boloka litšenyehelo, ho etsa hore e be khetho e ratoang bakeng sa mesebetsi e mengata ea merafo.

Ho tšoarella le ho phela halelele

Ho tšoarella ke ntho ea bohlokoa ho lisebelisoa tsa merafo. Likarolo tse phahameng tsa tšepe tsa manganese hangata li bonts'a abophelo bo bolelele ba tšebeletsoho feta lisebelisoa tse ling, haholo-holo tlas'a maemo a tloaelehileng a ho sebetsa. Mohlala, limaraka tse phahameng tsa tšepe tsa manganese, joalo ka Mn22, li bonts'a moaparo o ikhethang le ho hanyetsa tšusumetso. Li-liner tsena li ka tšoarella lipakengLihora tse 250 ho isa ho tse 500maemong a abrasive, haholo outlasting standard manganese tšepe.

Ha ho bapisoa, likarolo tsa tšepe tsa alloy li ka tšoarella ho fetamakhetlo a mararo ho fetaho feta tšepe e phahameng ea manganese tlas'a maemo a ts'oanang a ts'ebetso. Liteko tsa laboratori li tiisa hore lipoleiti tsa tšepe tsa alloy li hana ho senyeha hamonate, haholo-holo libakeng tse nang le abrasive. Tafole e latelang e akaretsa litšobotsi tse tšoarellang tsa tšepe e phahameng ea manganese khahlano le tšepe ea alloy:

| Thepa | Tšepe ea Manganese e phahameng | Alloy Steel |

|---|---|---|

| Apara Resistance | E atisa ho apara kapele maemong a itseng | E hanela ho apara hantle, e tšoarella nako e telele |

| Impact Resistance | Tšusumetso e ntle ea ho hanyetsa | Boiketlo bo itekanetseng ba ho hanyetsa |

| Ho thatafala | E ka sebetsa ka thata-thata empa ea fokotsa boima bo akaretsang | Boima bo phahameng (HRC 48-51) |

| Ho tšoarella | Ka kakaretso ha e tšoarelle ho feta tšepe ea alloy | E ka tšoarella nako e telele ka makhetlo a mararo |

| Monyetla oa ho Fetola | E ka fetoloa ka chromium/molybdenum | Ha se hangata e fetotsoeng |

Bokhoni ba ho thatafatsa mosebetsi oa tšepe e phahameng ea manganese e o lumella ho monya matla a bohlokoa nakong ea ts'ebetso. Thepa ena e ntlafatsa ho tšoarella ha eona, e etsa hore e tšoanelehe bakeng sa lits'ebetso tse nang le tšusumetso e phahameng merafong.

Litšenyehelo-Ka katleho

Tšebeliso e ntle ea litšenyehelo ke monyetla o mong oa bohlokoa oa tšepe e phahameng ea manganese. Le hoja matsete a pele a ka 'na a e-ba holimo ho feta mekhoa e meng, chelete ea nako e telele ea polokelo hangata e feta litšenyehelo tsena. Likarolo tsa tšepe tse phahameng tsa manganese hangata li fana ka bophelo bo atolositsoeng ba ts'ebeletso ha bo bapisoa le lisebelisoa tse ling. Nako ena ea nako e telele e fetolela ho fokotseha ha makhetlo a ho fetola le ho fokotsa litšenyehelo tsa tlhokomelo.

Ho feta moo, tšebeliso ea tšepe e phahameng ea manganese e ka lebisa ho boloka chelete e ngata litšenyehelong tsa ts'ebetso. Likhamphani li ka fokotsa litšenyehelo tsa nako le ho lokisa, e leng se tlatselletsang katlehong e akaretsang. Ka mohlala, likarolo tse phahameng tsa tšepe ea chrome alloy li ka tšoarella nako e telele ka makhetlo a mararo ho isa ho a mane ho feta lipoleiti tse tloaelehileng tsa tšepe tsa manganese. Nako ena e atolositsoeng ea bophelo e fokotsa tlhoko ea ho nkeloa sebaka khafetsa, e qetellang e lebisa litšenyehelong tse tlase.

Lits'ebetso tsa Ts'epe ea Manganese e Phahameng ka Merafong

Li-Crusher Liners

Tšepe ea manganese e phahamenge bapala karolo ea bohlokoa tlhahisong ea li-crusher liner. Li-liner tsena ke likarolo tsa bohlokoa ka mefuta e fapanengliindasteri tse apereng liaparo tse phahameng, tse kenyelletsang ho chekoa ka majoe, merafo, ho cheka le lekala la mashala. Li mamella likhohlano tse matla le litlamorao tse sithabetsang, li netefatsa ts'ebetso e tsitsitseng ea li-crusher. Boemo bo phahameng ba ho sesa le bophelo bo atolositsoeng ba tšepe ea manganese bo etsa hore e be e loketseng bakeng sa lits'ebetso tse boima.

Tafole e latelang e totobatsa lintlafatso tsa ts'ebetso tse bonoang ha ho sebelisoa tšepe e phahameng ea manganese ho li-crusher liner:

| Ntlafatso ea Ts'ebetso | Tlhaloso |

|---|---|

| Excellent Wear Resistance | Pontšo ea lithapo tsa tšepe tse phahameng tsa manganesekhanyetso e ikhethang ea ho apara, ho lelefatsa bophelo ba lisebelisoa. |

| Thepa e Ithatafatsang | Li-liner li eketseha ka thata holim'a metsi ha nako e ntse e ea, li matlafatsa ho hanyetsa le ho sebetsa hantle. |

| Sebetsa se Ntlafetseng sa Crusher | Boima bo phahameng bo lebisa ho ho senya ka katleho, ho fokotsa tahlehelo ea matla le ho ntlafatsa bokhoni ba tlhahiso. |

| Nako e Fokotseng ea Tlhokomelo ea Lisebelisoa | Ho thatafala hoa holimo ho fella ka ho apara butle, ho fokotsa tlhoko ea ho nkela sebaka khafetsa. |

| Ntlafatso ea Kakaretso ea Tlhahiso ka Kakaretso | Bophelo bo bolelele ba ts'ebeletso le nako e fokotsehileng ea nako e fokotsang ts'ebetso ea tlhahiso le tlhahiso e akaretsang. |

| Khanyetso e Matla ea Tšusumetso | Li-liners li mamella tšusumetso e matla, ho boloka ts'ebetso e tsitsitseng le ho fokotsa litšenyehelo tsa tlhokomelo. |

| Litšenyehelo tse Fokotsoeng tsa Ts'ebetso | Tlhokomelo e fokolang khafetsa le ho nkela sebaka ho fokotsa litšenyehelo tsa ts'ebetso le ho ntlafatsa melemo ea moruo. |

Mehlahare le Cone Crushers

Manganese tšepe e phahameng haholoe ntlafatsa ts'ebetso ea li-crushers tsa mohlahare le likhoune. Hoo e ka bang 70% eali-crushers tsa mohlahare le tsa khouneindastering ea merafo sebelisa likarolo tse phahameng tsa tšepe ea manganese. Boitsebiso bona bo fana kaho tiea le ho tšoarella ho ikhethang, ea bohlokoa bakeng sa ho monya litšisinyeho libakeng tse nang le khatello e phahameng.

Thepa e ikhethang ea tšepe e phahameng ea manganese e e lumella ho monya le ho senya matla a ts'oenyeho ka katleho. Sena se thibela mapetsong kapa ho robeha, e leng sa bohlokoa bakeng sa ho lokisa thepa e thata. Lintlha tse latelang li akaretsa melemo ea tšepe e phahameng ea manganese ka har'a mohlahare le li-cone crushers:

- Tšebeliso ea tšepe ea manganese e thatafala ka tšusumetso e 'ngoe le e' ngoe, e eketsa khanyetso ea eona ho abrasion.

- E boloka boima bo phahameng, e monya matla a bohlokoa ntle le ho phatloha.

- Motsoako ona o o lumella ho sebetsa hantle maemong a abrasive le a nang le tšusumetso e phahameng.

Ka ho fokotsa tlhokahalo ea ho fetola likarolo khafetsa, tšepe e phahameng ea manganese e fokotsa nako ea ho theoha le ho ntlafatsa tlhahiso ka kakaretso. Tšebeliso ea eona ea litšenyehelo e bakoa ke nako e telele ea bophelo ea likaroloana, e leng se lebisang litlhoko tse tlaase tsa tlhokomelo.

Kameho ea Tšepe e Phahameng ea Manganese ho Sebetsa le Tlhahiso

Nako ea ho phomola e fokotsehile

Litšepe tse phahameng tsa manganese li fokotsa haholo nako ea ho theoha ha mesebetsi ea merafo. Ho tšoarella ha eona leapara khanyetsolebisa ho bophelo bo bolelele ba tšebeletso bakeng sa likarolo. Ka mohlala, li-liner tsa tšepe tse phahameng tsa manganese li ka tšoarella ka karolelano eaMatsatsi a 35, ha ho bapisoa le matsatsi a 19 feela bakeng sa li-liner tsa OEM tse fetileng. Ntlafatso ena e lumella lik'hamphani tsa merafo ho boloka ts'ebetso e tsoelang pele ntle le litšitiso khafetsa bakeng sa ho nkela likarolo tse ling.

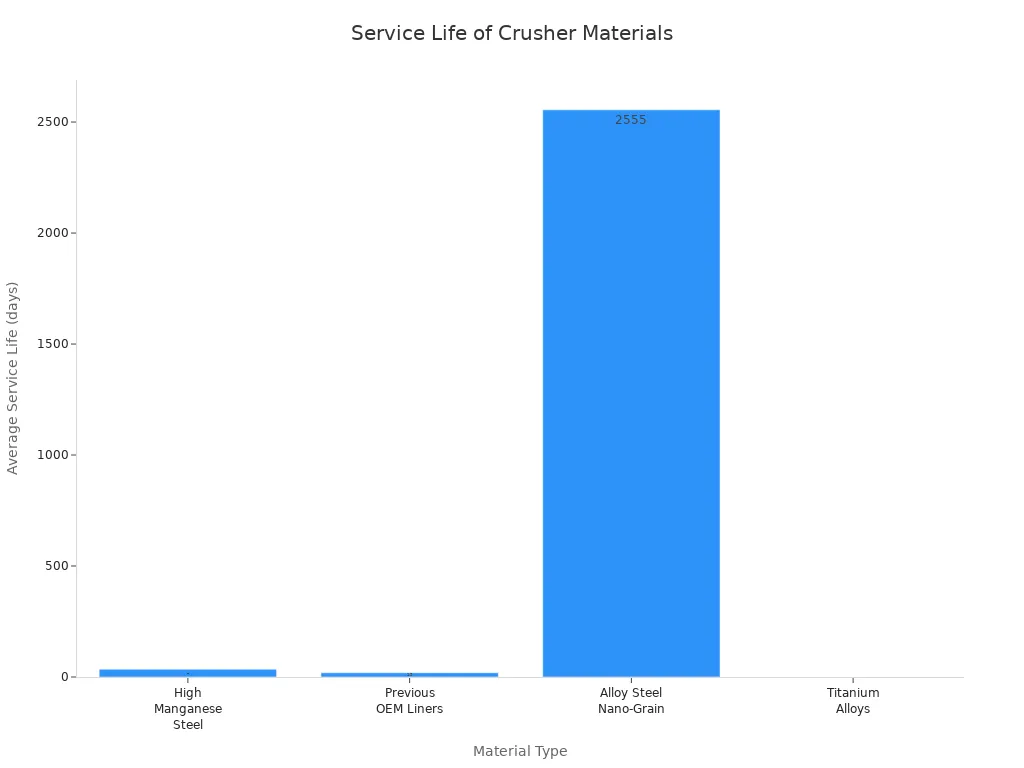

| Mofuta oa Boitsebiso | Karolelano ea Bophelo ba Tšebeletso | Lintlha |

|---|---|---|

| Tšepe ea Manganese e Phahameng (Xtralloy) | Matsatsi a 35 | Ntlafatso e kholo ho feta li-liner tsa OEM tse fetileng. |

| Liner tsa OEM tse fetileng | 19 matsatsi | Bophelo bo tlase ba ts'ebeletso ha bo bapisoa le Xtralloy. |

| Alloy Steel e nang le Nano-Grain Forging | 5-7 lilemo | Nako e telele ea bophelo ho feta tšepe e phahameng ea manganese. |

| Lisebelisoa tsa Titanium | 7-9 lilemo | Bophelo bo phahameng ha bo bapisoa le tšepe e phahameng ea manganese. |

Nako e telele ea bophelo ea likarolo tse phahameng tsa tšepe ea manganese e lebisa ho koaleheng ha tlhokomelo ho fokolang. Bareki ba tlalehile ho fokotseha ha nako ea tlhokomelo ho fihlela ho30%ka mor'a ho fetola likarolo tse phahameng tsa tšepe ea manganese. Phokotso ena ha e ntlafatse tlhahiso feela empa e boetse e kenya letsoho tabeng ea ho baballa litšenyehelo.

Melemo ea Ts'ebetso e Ntlafetseng

Litšepe tse phahameng tsa manganese li ntlafatsa litekanyetso tse 'maloa tsa ts'ebetso ho lisebelisoa tsa ho senya merafo. Lintho tsa eona tse ikhethang li ntlafatsa ho hanyetsa ho apara, ho tiea, le ho tšoarella ka kakaretso. Ka lebaka leo, ts'ebetso ea merafo e ba le boiphihlelo:

- Apara Resistance: Tšepe e phahameng ea manganese e ba thata le ho feta ha nako e ntse e hohlana, e etsa hore e be e loketseng bakeng sa lits'ebetso moo ho khathatsoang ke ho apara.

- Mathata: Ho tiea ha thepa ho matlafatsa bokhoni ba eona ba ho mamella tšusumetso le matla a abrasive, a bohlokoa tikolohong ea merafo.

- Ho tšoarella: Ho tšoarella ka kakaretso ho ntlafalitsoe, ho lebisang ho fokotseheng ha nako le litšenyehelo tse tlase tsa tlhokomelo.

Mokhoa oa ho bolela esale pele bakeng sa bophelo bohle ba lipoleiti tse silakanyang o bonts'a motso o tlase o bolelang phoso ea square (RMSE) eaLihora tse 0.0614. Ho nepahala hona ho bontša hore tšepe e phahameng ea manganese e ntlafatsa haholo tlhahiso, ka nako ea bophelo ho tloha lihora tse 746 ho isa ho tse 6902. Likhamphani tse shebaneng le likarolo tsa boleng li bile le ntlafatso ea tlhahiso e fihlang ho 20%.

Ka ho tsetela likarolong tse phahameng tsa tšepe tsa manganese, ts'ebetso ea merafo e ka fihlela litekanyetso tse betere tsa ts'ebetso le katleho ea ts'ebetso.

Tšepe ea manganese e phahamengThepa ea 's e etsa hore e be ea bohlokoa haholo lits'ebetsong tsa ho senya merafo. Sebopeho sa eona se ikhethang se matlafatsa nako e telele, ho hanyetsa ho apara, le ho tiea. Boitsebiso bona bo ntlafatsa haholo tlhahiso le ho boloka litšenyehelo bakeng sa mesebetsi ea merafo. Melemo ea bohlokoa e kenyelletsa:

- Linako tse atolositsoeng tsa tlhokomelo ka30–40%

- Ho fokotsa makhetlo a mangata a ho fetola likarolo

- Litsenyehelo tse tlase tsa ts'ebetso

Tlhokahalo ea tšepe e phahameng ea manganese ee reretsoeng ho phahamaka baka la tshebetso e sa lekanngweng le maemo maemong a thata. Ha mahlale a merafo a ntse a fetoha, ts'ebeliso e tsoelang pele ea tšepe e phahameng ea manganese e ntse e le bohlokoa bakeng sa ts'ebetso e nepahetseng.

| Thepa/Mosebetsi | Tlhaloso |

|---|---|

| Moemeli oa Deoxidising | E tlosa litšila tsa oksijene le sebabole tšepeng e qhibilihisitsoeng, e ntlafatsa matla le ho tšoarella. |

| Alloy Strengthener | E matlafatsa ho tiea, ho thatafala, le ho hanyetsa ho apara ka ho etsa metsoako e tsitsitseng ka carbon. |

| Matlafatsa Matla | E eketsa ho thatafala, ho etsa tšepe e loketseng likopo tsa sebopeho tlas'a khatello ea maikutlo. |

| Tšepe ea Manganese e Phahameng | E na le 12–14% ea manganese, e tsejoang ka thepa e ikhethang e thatafatsang mosebetsi, e loketseng merafo. |

LBH

tšepe e phahameng ea manganese ke eng?

Tšepe e phahameng ea manganese ke motsoako o nang le 11-14% ea manganese. E tsebahala ka ho tiea ha eona ho ikhethang le ho hanyetsa ho roala, ho etsa hore e be e loketseng bakeng sa lits'ebetso tsa merafo.

Tšepe ea manganese e phahameng e sebetsa ka thata joang?

Mosebetsi o phahameng oa tšepe ea manganese oa thatafala ha o le tlas'a tšusumetso. Ts'ebetso ena e eketsa boima ba eona, ho e lumella ho monya matla a mangata le ho hanela ho roala.

Lisebelisoa tsa mantlha tsa tšepe e phahameng ea manganese merafong ke life?

Ts'epe e phahameng ea manganese e sebelisoa haholo ho li-crusher liner,li-crushers tsa mohlahare, le li-cone crushers. Ho tšoarella ha eona ho etsa hore e tšoanelehe bakeng sa libaka tse nang le tšusumetso e phahameng le tse senyang.

Ke hobane'ng ha tšepe e phahameng ea manganese e boloka chelete e ngata?

Le hoja tšepe e phahameng ea manganese e ka ba le litšenyehelo tse phahameng tsa pele, bophelo ba eona bo bolelele ba tšebeletso lelitlhoko tse fokotsehileng tsa tlhokomeloe lebisa ho poloko e kholo ea nako.

Tšepe e phahameng ea manganese e bapisoa joang le lisebelisoa tse ling?

Tšepe e phahameng ea manganese e fana ka khanyetso e phahameng ea ho apara le ho tiea ha ho bapisoa le lisebelisoa tse ling tse kang tšepe ea alloy. Sena se etsa hore e be khetho e ratoang bakeng sa ho batla likopo tsa merafo.

Nako ea poso: Oct-24-2025