Tlhaloso

Ho hlahisa lihlahisoa tsa boleng bo holimo ka theko e tlase ka ts'ebetso e phahameng ka ho fetesisa le ho ts'epahala, o tlameha ho khetha likarolo tsa moaparo tse ntlafalitsoeng bakeng sa ts'ebeliso ea hau e itseng ea ho senya. Lintlha tse kholo tse lokelang ho nahanoa ka tsela e latelang:

1. Mofuta oa mafika kapa liminerale tse lokelang ho siloa.

2. Boholo ba likaroloana tsa lintho tse bonahalang, mongobo le boemo ba boima ba Mohs.

3. Thepa le bophelo ba mekoallo e otlang e neng e sebelisoa pele.

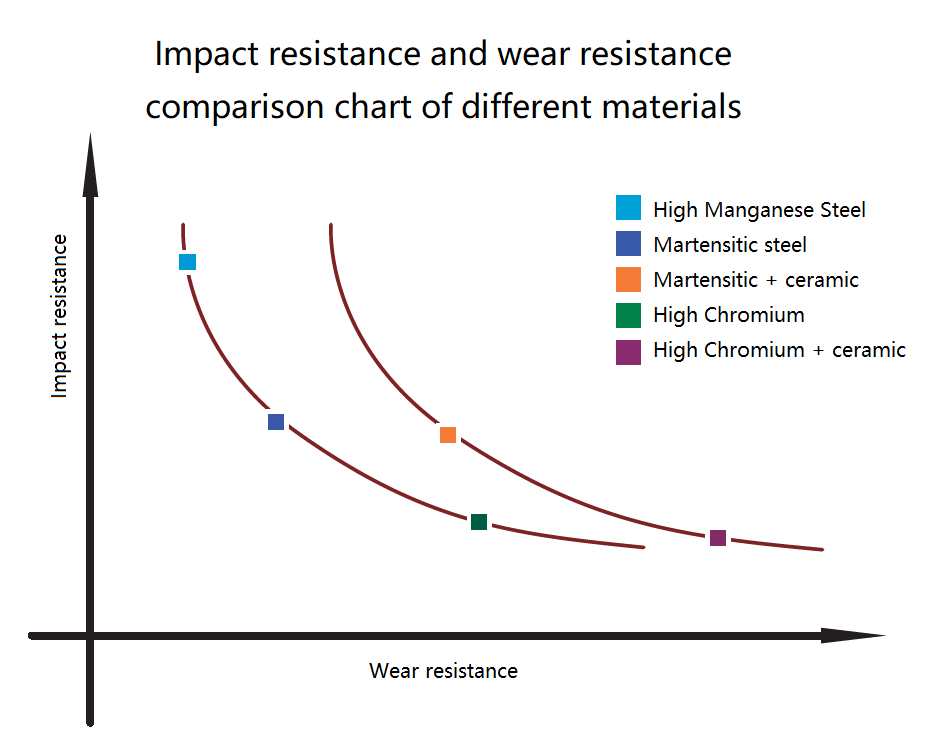

Ka kakaretso, ho hanyetsa ho roala (kapa ho thatafala) ha lisebelisoa tsa tšepe tse kentsoeng leboteng ho tla fokotsa ho hanyetsa ha eona (kapa ho tiea). Mokhoa oa ho kenya lipitsa tsa letsopa ka thepa ea matrix ea tšepe e ka eketsa haholo ho hanyetsa ha eona ntle le ho ama ho hanyetsa ha eona.

Tšepe ea Manganese e phahameng

Tšepe e phahameng ea manganese ke thepa e sa sebetseng e nang le nalane e telele ebile e sebelisitsoe haholo ho li-crushers. Litšepe tse phahameng tsa manganese li na le matla a matla a ho hanyetsa. Ho hanyetsa ho apara hangata ho amana le khatello le tšusumetso holim'a eona. Ha ts'usumetso e kholo e sebelisoa, sebopeho sa austenite se holim'a metsi se ka thatafatsoa ho HRC50 kapa ho feta.

Lihamore tse phahameng tsa tšepe tsa manganese hangata li khothaletsoa feela bakeng sa ho silakanya ka thepa ea boholo bo boholo ba phepelo le boima bo tlase.

Motsoako oa lik'hemik'hale oa tšepe e phahameng ea manganese

| Lintho tse bonahalang | Sebopeho sa Lik'hemik'hale | Thepa ea Machanical | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1,25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2,5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2,5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

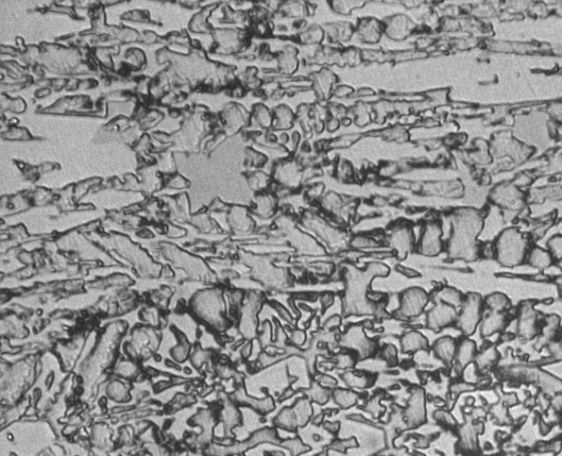

Microstructure ea tšepe e phahameng ea manganese

Tšepe ea Martensitic

Sebopeho sa Martensite se thehoa ka ho pholile ka potlako ha tšepe ea carbon e tletseng ka ho feletseng. Liathomo tsa carbon li ka hasana ho tsoa ho martensite feela ts'ebetsong ea ho pholisa ka potlako kamora kalafo ea mocheso. Tšepe ea Martensitic e na le boima bo phahameng ho feta tšepe e phahameng ea manganese, empa ho hanyetsa ha eona hoa fokotseha. Ho thatafala ha tšepe ea martensitic ho pakeng tsa HRC46-56. Ho ipapisitsoe le thepa ena, "martensitic steel blow" bar hangata e khothaletsoa bakeng sa lits'ebetso tse hatelletsoeng moo ho nang le ts'usumetso e tlase empa ho hlokahala khanyetso e phahameng.

Microstructure ea tšepe ea martensitic

Tshweu ya Chromium e Phahameng

Ka tšepe e tšoeu ea chromium e phahameng, khabone e kopantsoe le chromium ka sebopeho sa chromium carbide. Aene e tšoeu ea chromium e na le khanyetso e ikhethang. Kamora kalafo ea mocheso, boima ba eona bo ka fihla ho 60-64HRC, empa ho hanyetsa ha eona hoa fokotseha. Ha ho bapisoa le tšepe e phahameng ea manganese le tšepe ea martensitic, tšepe e phahameng ea chromium e na le khanyetso e phahameng ka ho fetesisa, empa khanyetso ea eona le eona e tlase haholo.

Ka tšepe e tšoeu ea chromium e phahameng, khabone e kopantsoe le chromium ka sebopeho sa chromium carbide. Aene e tšoeu ea chromium e na le khanyetso e ikhethang. Kamora kalafo ea mocheso, boima ba eona bo ka fihla ho 60-64HRC, empa ho hanyetsa ha eona hoa fokotseha. Ha ho bapisoa le tšepe e phahameng ea manganese le tšepe ea martensitic, tšepe e phahameng ea chromium e na le khanyetso e phahameng ka ho fetesisa, empa khanyetso ea eona le eona e tlase haholo.

Motsoako oa lik'hemik'hale oa tšepe e tšoeu ea chromium e phahameng

| ASTM A532 | Tlhaloso | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | B | Ni-Cr-Lc | 2.4-3.0 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | C | Ni-Cr-GB | 2.5-3.7 | 2.0 Max | 0.8 Max | 4.0 Max | 1.0-2.5 | 1.0 Max |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 Max | 2.0 Max | 4.5-7.0 | 7.0-11.0 | 1.5 Max |

| II | A | 12Kr | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.40-0,60 | 11.0-14.0 | 3.0 Max |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.80-1,20 | 14.0-18.0 | 3.0 Max |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Max | 1.0-2.2 | 0.80-1,20 | 18.0-23.0 | 3.0 Max |

| III | A | 25Kr | 2.8-3.3 | 2.0 Max | 1.5 Max | 0.40-0,60 | 23.0-30.0 | 3.0 Max |

Microstructure ea High Chromium White iron

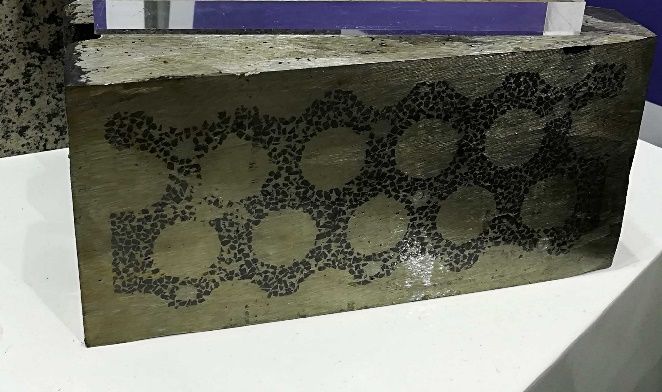

Ceramic-Metal Composite Material (CMC)

CMC ke thepa e sa senyeheng e kopanyang ho tiea ho hotle ha thepa ea tšepe (tšepe ea martensitic kapa tšepe e entsoeng ka chromium e phahameng) le boima bo phahameng haholo ba lirafshoa tsa indasteri. Likaroloana tsa Ceramic tsa boholo bo itseng li tšoaroa ka ho khetheha ho theha 'mele oa porous oa likaroloana tsa ceramic. Tšepe e qhibilihisitsoeng e kenella ka ho feletseng ka har'a li-interstices tsa sebopeho sa ceramic nakong ea ho lahla le ho kopana hantle le likaroloana tsa letsopa.

Moqapi ona o ka ntlafatsa ka katleho ts'ebetso e khahlanong le ho roala sefahleho sa ho sebetsa; ka nako e ts'oanang, 'mele o ka sehloohong oa sekhahla kapa hamore o ntse o entsoe ka tšepe ho netefatsa ts'ebetso ea oona e sireletsehileng, ho rarolla ka katleho ho hanyetsana pakeng tsa ho apara ho hanyetsa le ho hanyetsa tšusumetso,' me e ka ikamahanya le maemo a fapaneng a ho sebetsa. E bula sebaka se secha bakeng sa khetho ea likarolo tsa lisebelisoa tse apereng haholo bakeng sa basebelisi ba bangata, le ho theha melemo e metle ea moruo.

a.Martensitic Steel + Ceramic

Ha ho bapisoa le bar e tloaelehileng ea martensitic blow, hamore ea martensitic ceramic blown hamore e na le boima bo phahameng holim'a eona, empa ho hanyetsa hamore hamore ho ke ke ha fokotseha. Maemong a ho sebetsa, martensitic ceramic blowbar bar e ka ba sebaka se setle sa kopo mme hangata e ka fumana makhetlo a ka bang 2 kapa bophelo bo bolelele ba ts'ebeletso.

b. High Chromium White Iron +Ceramic

Le hoja tšepe e tloaelehileng e phahameng ea chromium e se e ntse e e-na le khanyetso e phahameng ea ho roala, ha thepa e silakanya ka thata e phahameng haholo, joalo ka granite, ho sebelisoa mekoallo e sa sebetseng ho feta ho lelefatsa bophelo ba bona ba ho sebetsa. Tabeng ena, tšepe e entsoeng ka chromium e phahameng e kentsoeng ka ceramic blow bar ke tharollo e molemo. Ka lebaka la ho kenngoa ha li-ceramics, ho thatafala ha sefahleho sa hamore e otlang ho ntse ho eketseha, 'me ho hanyetsa ha eona ho ntlafatsoa haholo, hangata makhetlo a 2 kapa nako e telele ea tšebeletso ho feta tšepe e tloaelehileng e phahameng ea chromium.

Melemo ea Ceramic-Metal Composite Material (CMC)

(1) E thata empa e se brittle, e thata ebile e sa khathatse, e finyella ho leka-lekana ha bobeli ba ho hanyetsa ho apara le ho ba thata haholo;

(2) boima ba ceramic ke 2100HV, 'me ho hanyetsa ho roala ho ka fihla makhetlo a 3 ho isa ho a 4 a lisebelisoa tse tloaelehileng tsa alloy;

(3) Moralo oa moralo oa motho ka mong, mohala o utloahalang haholoanyane;

(4) Bophelo bo bolelele ba tšebeletso le melemo e phahameng ea moruo.

Parameter ea lihlahisoa

| Mofuta oa Mochini | Moetso oa mochini |

| Metso | LT-NP 1007 |

| LT-NP 1110 | |

| LT-NP 1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441(QI440) | |

| QI340 (I-C13) | |

| CI124 | |

| CI224 | |

| Kleemann | MR110 EVO |

| MR130 EVO | |

| MR100Z | |

| MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-e ncha | |

| XH320 ea khale | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 hodimo) | |

| Powerscreen | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| Ke-120 | |

| Ke-130 | |

| Ke-140 | |

| Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| RM100 | |

| RM120 | |

| Tesab | RK-623 |

| RK-1012 | |

| Extec | C13 |

| Telsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Ntsu | 1400 |

| 1200 | |

| Seteraeke | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |