Lintho tse lahlanglihlahisoa tsa sebopeho joaloka aMochini oa ho Crusher or Gyratory Crusher. Ba thusa ho bopa tsohle ho tlohaLikarolo tsa Cone Crusherho aHamore ea tšepe ea Manganese. Khetho e nepahetseng ke ea bohlokoa. Sheba tafole ena ho tsoa setsing se holimo sa Europe:

| Sehlahisoa sa Ts'epe sa Selemo le Selemo | 23.000 lithane |

| Sekhahla sa Sekoli | 5–7% |

Mahlale a lisebelisoa a akaretsa tšepe, lirafshoa, li-polymers le li-composite. Ho tseba thepa e nepahetseng ea ho lahlela ho thusa baenjiniere ho matlafatsa boleng le ho khaola litšila.

Lintlha tsa bohlokoa

- Ho khetha thepa e nepahetseng ea ho lahla, joalo ka tšepe, tšepe,aluminium, kapa lipolasetiki, li ama ka ho toba boleng ba sehlahisoa, litšenyehelo, le tshebetso.

- Lisebelisoa tsa tšepe li na le tšepe 'me li matla empa li ka rusa, ha lisebelisoa tse se nang ferrous joalo ka aluminium le koporo li hanela mafome 'me li bobebe.

- Plastiki le lirafshoa li fana ka melemo e ikhethang e kang ho hanyetsa kutu le ho mamella mocheso, e leng se etsang hore e be tse loketseng bakeng sa lisebelisoa tse khethehileng.

Mefuta e ka Sehloohong ea Lisebelisoa tsa ho Lahlela

Lisebelisoa tsa Ferrous Casting: Tšepe le Tšepe

Lisebelisoa tsa tšepe tsa tšepe li kenyelletsa tšepe le tšepe. Litšepe tsena li na le tšepe e le karolo ea tsona ea mantlha. Ba phetha karolo e kholo mechineng e boima le kahong. Tšepe le tšepe li na le thepa e fapaneng. Tafole e ka tlase e bontša kamoo li bapisang kateng:

| Thepa/ Sebopeho | Tšepe ea ho Lahlela | Tšepe (ho kenyeletsoa litšepe tse bonolo le tsa carbon) |

|---|---|---|

| Litaba tsa Carbon | 2–4.5% | 0.16–2.1% |

| Thepa ea Mechini | Matla a phahameng a hatellang; brittle | Ductile; matla a ho tsitsa a fapana |

| Khanyetso ea Corrosion | Ho molemo moeeng o silafetseng | E senya kapele |

| Boikemisetso | Bonolo (tšepe e bohlooho); e thata (tšepe e tšoeu) | E ntle, e fapana ka mofuta |

| Lisebelisoa | Li-block tsa enjine, li-rotor tse robehileng | Li-gears, liliba, likarolo tsa likoloi |

Lisebelisoa tsa tšepe li sebetsa hantle bakeng sa li-block tsa enjine le matlo a pompo.Lisebelisoa tsa tšepee lekana likere, li-spring, le likarolo tse ngata tsa koloi. Mofuta o mong le o mong o tlisa matla a oona tafoleng.

Lintho tse se nang Ferrous Casting: Aluminium, Koporo, Magnesium, Zinc

Lisebelisoa tsa ho lahla tse se nang ferrous ha li na tšepe e le ntho e ka sehloohong. Aluminium, koporo, magnesium le zinki ke tsa sehlopha sena. Litšepe tsena li bobebe ho feta tšepe le tšepe. Lisebelisoa tsa ho lahla Aluminium li tumme bakeng sa likarolo tsa koloi le liforeimi tsa sefofane. Lisebelisoa tsa koporo li sebetsa likarolong tsa motlakase hobane li tsamaisa motlakase hantle. Lisebelisoa tsa magnesium le zinki li thusa ho etsa likarolo tse bobebe bakeng sa lisebelisoa tsa elektroniki le lisebelisoa. Litšepe tse se nang ferrous li hanela mafome 'me li fana ka matla a matle bakeng sa boima ba tsona.

Lintho tse ling tsa ho Lahlela: Plastiki le Ceramics

Lisebelisoa tse ling ha se litšepe ho hang. Plastiki le ceramic li fana ka melemo e ikhethang. Plastiki e ka etsa libopeho tse rarahaneng le ho hanela kutu. Li-ceramics li emela mocheso o phahameng. Batho ba boholo-holo ba ne ba sebelisa lintho tse entsoeng ka ceramic bakeng sa ho qhibilihisa koporo. Li-ceramics tsa sejoale-joale, joalo ka nano-zirconia, li bonts'a ts'ebetso e ntle le ho feta. Li na le matla a holimo a ho kobeha, ho tiea, le ho hanyetsa mongoao. Li-ceramics tsena li thusa ho etsa likarolo tse tšesaane, tse matla tsa mehala le lioache.

Plastiki le lirafshoa li bula mamati a macha bakeng sa lisebelisoa tsa ho lahlela, haholo-holo moo ho hanyetsa mocheso kapa libopeho tse khethehileng li leng bohlokoa.

Thepa le Tšebeliso ea Mefuta ea Lisebelisoa tsa ho Lahlela

Lisebelisoa tsa ho Lahlela Tšepe

Lisebelisoa tsa tšepe li hlahella ka lebaka la matla a eona a ho hatella. Hangata batho ba e sebelisa bakeng sa likholomo, liboloko tsa enjine le mechine e boima. Grey cast iron e na le li-flakes tsa carbon, tse etsang hore ho be bonolo ho sebetsa ka mochine empa hape e brittle. Tšepe ea tšepe e tšoeu, e nang le khabone joalo ka tšepe ea carbide, e fana ka matla a betere le ho se sebetse hantle.

- Matla:

- E sebetsana le meroalo e boima hantle.

- E ntle bakeng sa likarolo tse sa kobehang haholo.

- Mefokolo:

- Brittle mme e ka robeha tlasa tsitsipano.

- E atisa ho ba le mafome, haholo-holo libakeng tse mongobo.

Ho eketsa lintho tse kang silicon, nickel, kapa chromium ho ka matlafatsa khanyetso ea kutu le ho tšoarella. Ho penta kamehla le ho hlahloba ho thusa ho thibela mafome le ho boloka litšepe li le boemong bo botle.

Liteko li bontša hore lehlabathe le sebelisetsoang ho etsa tšepe le khona ho mamella mocheso o phahameng, empa bokaholimo ba lona bo itšetlehile ka boholo ba lijo-thollo le sebōpeho sa lehlabathe. Sena se ama tsela eo sehlahisoa sa ho qetela se ikutloang se le boreleli kapa se thata kateng.

Lisebelisoa tsa ho Lahlela Tšepe

Lisebelisoa tsa tšepe tsa tšepe li tlisa motsoako oa matla, ductility, le ho tiea. Batho ba khetha tšepe bakeng sa likere, liliba le likarolo tsa koloi hobane e khona ho sebetsana le tsitsipano le khatello. Thepa ea tšepe e fetoha ka li-alloys le liphekolo tse fapaneng.

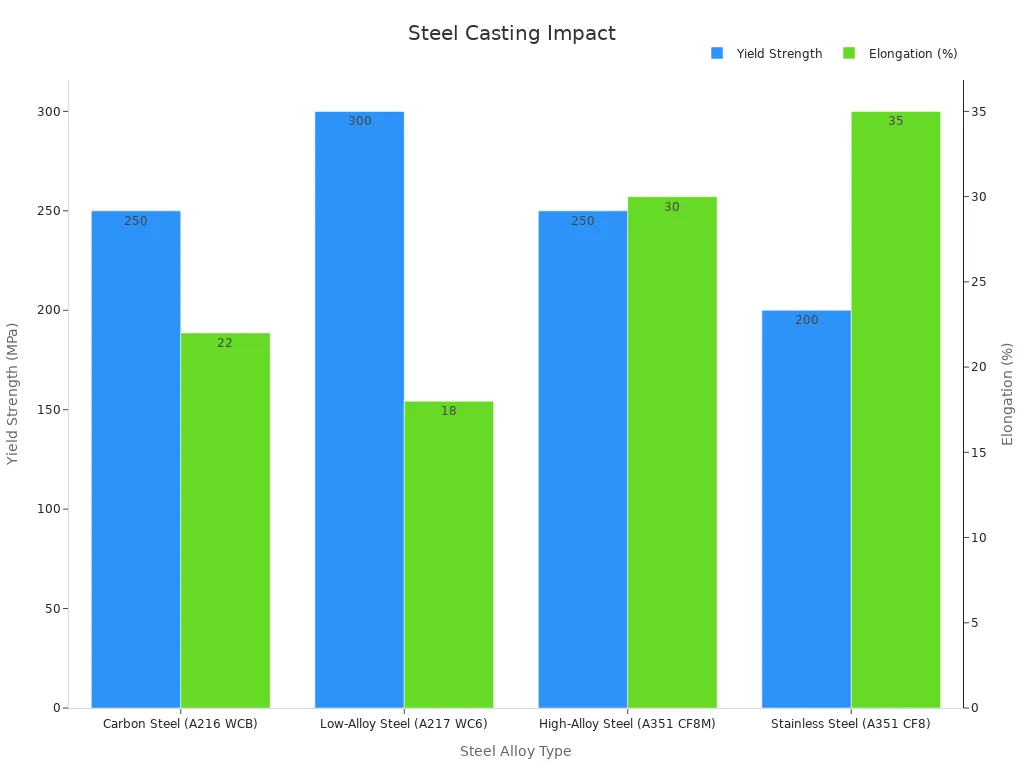

| Mofuta oa tšepe ea tšepe | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Khanyetso ea Corrosion |

|---|---|---|---|---|

| Carbon Steel (A216 WCB) | 250 | 450-650 | 22 | Mafutsana |

| Tšepe ea Alloy e Tlase (A217 WC6) | 300 | 550-750 | 18 | E lokileng |

| Tšepe e Phahameng ea Alloy (A351 CF8M) | 250 | 500-700 | 30 | E kgabane |

| Stainless Steel (A351 CF8) | 200 | 450-650 | 35 | E kgabane |

Ts'ebetso ea tšepe e itšetlehile ka hore na e etsoa joang. Ho pholisa ka potlako ho etsa lithollo tse nyane, tse etsang hore tšepe e be matla. Phekolo ea mocheso le mekhoa e hlokolosi ea ho lahlela le eona e ka ntlafatsa ho tiea le ho fokotsa likoli joalo ka li-pores.

Lisebelisoa tsa ho Lahlela Aluminium

Lisebelisoa tsa ho lahla Aluminium li tumme ka boima ba tsona bo bobebe le ho feto-fetoha ha maemo. E tloaelehile likarolong tsa koloi, liforeimi tsa sefofane le lisebelisoa tsa elektronike. Aluminium e ikhetha ka tekanyo ea eona e ntle ea matla le boima ba 'mele le ho hanyetsa mafome ka tsela e babatsehang.

| Thepa/Sebopeho | Aluminium e entsoeng | Thepa tšepe | Tšepe e Bohlooho |

|---|---|---|---|

| Botenya | 2.7g/cm³ | 7.7–7.85 g/cm³ | 7.1–7.3 g/cm³ |

| Matla a tšepe | 100–400 MPa (ho fihla ho 710 MPa bakeng sa lisebelisoa tse ling) | 340-1800 MPa | 150-400 MPa |

| Melting Point | 570–655°C | 1450–1520°C | 1150–1250°C |

| Thermal Conductivity | 120–180 W/m·K | E itekanetseng | ~46 W/m·K |

| Motlakase Conductivity | E ntle | Mafutsana | Mafutsana |

| Boikemisetso | Bonolo | E itekanetseng | E ntle empa e brittle |

| Khanyetso ea Corrosion | E kgabane | E itekanetseng | Mafutsana |

| Vibration Damping | E itekanetseng | E ntle | E kgabane |

| Litšenyehelo | E tlase bakeng sa tlhahiso ea bongata | Phahameng | E itekanetseng |

- Melemo:

- E etsa libopeho tse rarahaneng ka ho nepahala ho phahameng.

- E boloka matla ka lebaka la sebaka se tlase sa ho qhibiliha.

- E hanela kutu, kahoo e tšoarella ka ntle nako e telele.

- E ntle bakeng sa tlhahiso e phahameng.

- Meeli:

- E seng matla joalo ka tšepe.

- E ka ba brittle ka li-alloys tse ling.

- E hloka taolo e hlokolosi ho qoba likoli joalo ka porosity.

Tlhahlobo ea lipalo-palo e bontša hore boleng ba aluminium e qhibiliha le boteng ba bofokoli bo na le tšusumetso e kholo ho matla le ho tiea. Baenjiniere ba sebelisa liteko tse khethehileng le software ho hlahloba le ho ntlafatsa boleng ba ho lahla.

Lisebelisoa tsa ho Lahlela Koporo

Lisebelisoa tsa koporo li tsebahala haholo ka motlakase le mocheso oa motlakase. Batho ba sebelisa lisebelisoa tsa koporo likarolong tsa motlakase, lipeipi tsa metsi le lintho tse khabisang. Li-alloys tsa koporo, joalo ka boronse le koporo, li fana ka matla a eketsehileng le ho hanyetsa kutu ho betere.

| Mohlala oa Alloy | Tšebeliso ea Motlakase (% IACS) | Microhardness (Vickers) | Yield Strength (MPa) |

|---|---|---|---|

| EML-200 | 80% | E bapisoa le EMI-10 | 614 ± 35 |

| EMI-10 | 60% | E bapisoa le EML-200 | 625 ± 17 |

Liphekolo tse kang undercooling e tebileng li ka matlafatsa conductivity ntle le ho lahleheloa ke matla. Ho eketsa lintho tse kang zinki kapa thini le hona ho ka ntlafatsa ho hanyetsa le ho tšoarella. Lisebelisoa tsa koporo li sebetsa hantle libakeng tse thata hobane li hanela kutu, haholo ha li kopantsoe le litšepe tse ling.

Lisebelisoa tsa Magnesium

Lisebelisoa tsa Magnesium ke tse bobebe ho feta litšepe tsohle tsa sebopeho. E nepahetse bakeng sa likarolo tse hlokang ho ba matla empa e se boima, joalo ka likoloi, lifofane le lisebelisoa tsa elektroniki. Li-alloys tsa Magnesium li na le karo-karolelano e phahameng ea boima ba 'mele' me li bonolo ho e sebelisa.

- Likarolo tsa Bohlokoa:

- E bobebe haholo, e thusang ho boloka mafura a likoloi.

- Ho satalla e ntle le castability.

- Matla a phahameng a khethehileng, haholo-holo ka li-alloys tsa cast.

Liteko tsa liteko li bontša hore ho eketsa masoba kapa libopeho tse khethehileng ho ka etsa hore magnesium e be bobebe le ho feta ntle le ho lahleheloa ke matla a mangata. Leha ho le joalo, magnesium e ka senyeha habonolo, ka hona, hangata ho sebelisoa litlolo kapa likarolo tsa alloying ho e sireletsa.

Lisebelisoa tsa ho Lahlela Zinc

Lisebelisoa tsa ho lahla zinki hangata li sebelisoa bakeng sa likarolo tse nyane, tse qaqileng. Ho bonolo ho lahla le ho tlatsa hlobo hantle, ho etsa hore e be ntle bakeng sa likere, lintho tsa ho bapala le lisebelisoa. Li-alloys tsa zinc li fana ka matla a matle le ho tiea ha boima ba tsona.

- Melemo:

- E ntle bakeng sa ho etsa libopeho tse rarahaneng.

- Khanyetso e ntle ea kutu.

- Sebaka se tlase sa ho qhibiliha se boloka matla nakong ea ho lahla.

- Mathata:

- Ha e matla joalo ka tšepe kapa aluminium.

- E ka ba brittle ha nako e ntse e ea, haholo-holo maemong a batang.

Lihlahisoa tsa zinki li tloaelehile indastering ea likoloi le tsa elektroniki hobane li kopanya ho nepahala le ho boloka litšenyehelo.

Lisebelisoa tsa ho Lahlela Plastiki

Lintho tse entsoeng ka polasetiki li bula likhetho tse ngata tsa moralo. E bobebe, e hanela ho bola, 'me e ka nka sebopeho leha e le sefe. Batho ba sebelisa lisebelisoa tsa polasetiki lisebelisoa tsa bongaka, thepa ea bareki le likarolo tsa likoloi.

- Thepa ea Mechini:

- Matla, ho satalla, le ho tiea ho itšetlehile ka mofuta oa polasetiki le hore na e etsoa joang.

- Ho kenya likhoele tse kang k'habone kapa khalase ho ka etsa hore polasetiki e be matla haholo.

| Thepa/ Thepa | Woodcast® | Lisebelisoa tsa Synthetic Casting | Plaster ea Paris (PoP) |

|---|---|---|---|

| Matla a Khatello | Phahameng | Tlase | Brittle |

| Matla a tšepe | Tlase | E phahameng | Brittle |

| Flexural Strength (MPa) | 14.24 | 12.93–18.96 | N/A |

| Ho hanyetsa Metsi | E ntle | E fapana | Mafutsana |

Li-castings tsa polasetiki li ka sebetsana le metsi le mocheso hantle, ho itšetlehile ka thepa. Tse ling ha li na chefo ebile li bolokehile bakeng sa tšebeliso ea bongaka. Tse ling li ka ’na tsa e-na le lik’hemik’hale tse hlokang ho tšoaroa ka hloko.

Lisebelisoa tsa Ceramic Casting

Lintho tse entsoeng ka ceramic li hlahella ka bokhoni ba tsona ba ho sebetsana le mocheso o phahameng. Li-ceramics li thata, ha li sebetse, 'me ha li ruse. Batho ba li sebelisa linthong tsa elektronike, sepakapaka, esita le mabenyane.

- Thermal Properties:

- E khona ho mamella mocheso ho fihlela ho 1300°C.

- E ntle haholo bakeng sa ho pata le ho sireletsa mocheso.

- Boiketlo:

- Lithaele tse feto-fetohang tsa ceramic li ka sebelisoa ho kenya letsoho hape bakeng sa lifofa-sebakeng.

- Li-ceramics tse tsoetseng pele li kopanya matla a phahameng le conductivity e tlaase ea mocheso.

Bafuputsi ba thehile lisebelisoa tse ncha tsa ceramic tse matla le tse tenyetsehang, tse etsang hore e be tse loketseng maemo a feteletseng joalo ka sebaka kapa tlhahiso ea theknoloji e phahameng.

Lisebelisoa tsa ho lahla ka ceramic li boloka sebōpeho le matla a tsona esita le tlas'a mocheso o matla, e leng se etsang hore e be tsa bohlokoa bakeng sa mekhoa e mengata ea kajeno.

Ho khetha thepa e nepahetseng ea ho lahlela ho bopa boleng ba sehlahisoa, litšenyehelo, le ts'ebetso. Baenjiniere ba bapisa mekhoa ea ho lahla le thepa ba sebelisa litafole le lithuto tsa liketsahalo tsa sebele tsa lefats'e ho bapisa thepa ka 'ngoe le tšebeliso ea eona e ntle ka ho fetisisa. Ho tseba lintlha tsena ho thusa lihlopha ho etsa likarolo tse betere, ho boloka chelete, le ho qoba liphoso tse bitsang chelete e ngata.

LBH

Phapang e kholo ke efe pakeng tsa lisebelisoa tsa ferrous le non-ferrous casting?

Lisebelisoa tsa tšepe li na le tšepe. Lisebelisoa tse se nang ferrous ha li. Mefuta e nang le ferrous hangata e boima ho feta 'me e ruse ka potlako. Mefuta e se nang ferrous e hanela mafome 'me e ikutloa e le bobebe.

Hobaneng ha lienjiniere li khetha aluminium bakeng sa ho lahla?

Aluminium e boima bo tlase ho feta tšepe. E hanela mafome le libopeho habonolo. Baenjiniere ba e rata bakeng sa likarolo tsa koloi, liforeimi tsa sefofane le lisebelisoa tsa elektroniki.

Na lipolasetiki le lirafshoa li khona ho sebetsana le mocheso o phahameng?

Li-ceramics li sebetsana le mocheso o phahameng haholo. Hangata polasetiki e qhibiliha ka mocheso o tlase. Baenjiniere ba khetha li-ceramics bakeng sa lionto kapa lienjine, ha lipolasetiki li lekana mesebetsi e pholileng.

Nako ea poso: Jun-17-2025