Lisebelisoa tsa phepelo li phetha karolo ea bohlokoa ho khethollang bophelo ba ts'ebeletso eadikarolo tsa mohlahare. Li-operators tse laolang boima, abrasiveness, particle size, le mongobo li ka lelefatsa nako ea bophelo eatšepe ea manganese likarolo tsa ho roala mohlahare.

- Ho thatafala ho phahameng le ho senya ho eketsa litekanyetso tsa ho fetola le tšebeliso ea matla.

- Mongobo le ho khomarela ho ka etsa hore ho be le plugging, ho lebisa tlhokomelong e eketsehileng.

- Saese e tsitsitseng ea lijo e thusa ho thibela nako ea ho theoha le ho ntlafatsa ts'ebetso ea crusher.

Ho khetha se nepahetsengmochini o senyang mohlaharelelikarolo tse silafetsenge theola litšenyehelo le ho matlafatsa ts'ebetso.

Lintlha tsa bohlokoa

- Ho thatafala le ho khopama ha lisebelisoa tsa phepelo li eketsa haholo ts'ebetso ea likarolo tsa li-crusher tsa mohlahare, kahoo basebelisi ba lokela ho fetola maemo le ho khetha lisebelisoa tse matla ho lelefatsa bophelo ba karolo e itseng.

- Ho laola boholo ba lijo le ho tlosa majoe a maholo kapa likotlo ho thusa ho thibela ho apara le ho thibela ho sa lekana, ho ntlafatsakatleho ea crusherle ho fokotsa tlhokomelo.

- Mongobo le lisebelisoa tse khomarelang li baka ho koala le khatello e eketsehileng likarolong tsa crusher, kahoo ho laola mongobo ka ho omisa le ho hlahloba ho boloka li-crushers li sebetsa hantle.

- Ho khetha tokelolisebelisoa tsa poleiti ea mohlahare'me meralo e ipapisitseng le thepa ea phepelo e ka atisa bophelo le ho theola nako.

- Ho hlahlojoa khafetsa, tlhokomelo e nepahetseng, le koetliso ea mokhanni li bohlokoa ho bona hore na li senyehile kapele le ho boloka li-crushers li sebetsa hantle nako e telele.

Lintho tsa Bohlokoa tsa Fepa le Mochini oa ho Crusher oa Jaw

Ho thatafala ha Lintho tse Fepang

Ho thatafala ho hlahella e le e 'ngoe ea lintho tsa bohlokoa ka ho fetisisa tse amang ho roala ha li-crusher tsa mohlahare. Majoe a thata, a kang granite kapa basalt, a hloka matla a mangata ho pshatla. Matla ana a eketsehileng a eketsa khatello ea maikutlo holim'a lipoleiti tsa mohlahare le li-liner. Ha basebetsi ba fepa lisebelisoa tse thata ka har'a mochini o silafatsang mohlahare, lipoleiti li ba le ho seha le ho seha ho eketsehileng. Liphuputso li bontša hore majoe a nang le matla a phahameng a ho hatella le ho robeha ho thata a baka lebelo la ho apara ka potlako. Hangata li-operators li hlokomela hore karolo ea ho lokolloa ha mehlahare e fela pele ha e sebetsana le likaroloana tse nyenyane, tse thata. Ho fetola litlhophiso tsa crusher ho ipapisitse le boima ba sejo ho ka thusa ho fokotsa ho khathala le ho lelefatsa bophelo ba karolo.

Abrasiveness le Mineral Composition

Abrasiveness le sebopeho sa diminerale le tsona li phetha karolo e kholo mekhoeng ea ho apara. Liminerale tse kang quartzite le granite li senya haholo. Liminerale tsena li sila khahlanong le lipoleiti tsa mohlahare, e leng ho bakang ho senyeha ha holimo ka potlako. Haeba phepo e na le karolo e phahameng ea liminerale tse senyang, tse tloaelehilenglisebelisoa tsa tšepe tsa manganesee ka tsofala kapele. Ho khetha thepa e nepahetseng ea liner, tse kang tšepe e phahameng ea chrome kapa li-alloys tse kopantsoeng, li ka thusa ho hanela mofuta ona oa ho apara. Basebelisi ba boetse ba lokela ho shebella tšilafalo ka har'a phepelo, kaha tšepe ea tramp kapa majoe a maholohali a ka baka ho putlama le ho peperana.

Keletso: Ho bapisa thepa ea liner le motsoako oa liminerale tsa phepelo ho ka lelefatsa nako ea ho sebetsa ka makhetlo a mahlano le ho fokotsa litšenyehelo tsa tlhokomelo.

Kabo ea boholo ba karolo le boholo

Boholo ba likaroloana le kabo ea eona li ama ka ho toba hore na lipoleiti tsa mohlahare li hloka ho nkeloa sebaka hangata hakae. Ha phepelo e na le majoe a mangata a maholo, libaka tse ling tsa lipoleiti tsa mohlahare li fumana liphello tse pheta-phetoang. Sena se lebisa ho apara ho sa lekaneng le ho nkeloa sebaka khafetsa. Litefiso tse feteletseng lijong li ka baka li-blockages, tse fokotsang nako ea bophelo ea lipoleiti. Kabo ea boholo ba phepo e laoloang hantle e khothalletsa esita le ho apara le ts'ebetso e tsitsitseng. Basebelisi ba behang leihlo le ho lokisa boholo ba phepelo ba ka fokotsa litšenyehelo tsa ts'ebetso mme ba boloka mochini oa crusher oa mohlahare o sebetsa hantle.

Mongobo le ho Khomarela

Mongobo oa lintho tse feptjoang o bapala karolo e kholo ts'ebetsong ea "blaw crusher". Ha thepa ea lijo e e-na le mongobo o phahameng, haholo-holo ha e kopantsoe le lichelete kapa letsopa, hangata e lebisa mathateng a ts'ebetso. Lisebelisoa tse khomarelang li atisa ho khomarela bokaholimo bo ka har'a crusher. Ho khomarela hona ho ka baka li-blockages, tse tsejoang hape e le ho koala, tse sitisang mokhoa oa ho senya.

Hangata baetsi ba thepa ba hlokomela hore thepa e ntle e mongobo, e kang letsopa, ha e arohane habonolo. Ho e-na le hoo, lisebelisoa tsena li kopana ho ba boima bo teteaneng ka har'a kamore e pshatlehang. Ts'ebetso ena, e bitsoang "pancaking," e eketsa moroalo mochining oa crusher. Haeba e sa hlokomeloe, ho panka ho ka emisa mochine ka ho feletseng. Le ha mongobo o sa phahamise ka kotloloho sekhahla sa ho roala ha lipoleiti tsa mohlahare kapa li-liner, ho koaloa ho bakoang ke ho koala le moroalo oa enjene ho ka fokotsa ts'ebetso mme ho ka lebisa ho aparoa ka potlako ha nako.

Mehato e 'maloa e sebetsang e thusa ho laola mongobo le ho khomarela lijong:

- Ho omisa phepelo esale pele ho fokotsa mongobo o ka tlase ho 5% ho thusa ho thibela thepa ho khomarela.

- Ho hlahlobisisa likotlo pele u fepa mochini o senyang ho fokotsa kotsi ea ho koala.

- Ho kenya li-anti-stick liner, tse kang libaka tse koahetsoeng ke Teflon ka har'a li-chute tsa phepelo, ho fokotsa ho khomarela lintho tse bonahalang.

- Ho sebelisa mabota a baffle ho tsamaisa phallo ea thepa, haholo-holo ka li-feeders tse sisinyehang, ho ka fokotsa ho koala.

Tlhokomeliso: Basebelisi ba hlokomelang maemo a mongobo le ho fetola lits'ebetso tsa bona ba ka boloka ts'ebetso ea crusher e bonolo le ho lelefatsa bophelo ba likarolo tsa ts'ebetso.

Ho laola mongobo le ho khomarela linthong tsa phepelo ha ho ntlafatse ts'epahalo ea crusher feela empa hape ho theola litšenyehelo tsa tlhokomelo. Ka ho nka mehato ena, basebetsi ba etsa bonnete ba hore metjhini e pshatlang mohlahareng e sebetsa hantle, leha e lokisa lisebelisoa tse thata.

Kameho ea Thepa ea Feed ho Likarolo tsa Mochini oa Jaw Crusher

Liphello tse thata ho Jaw Plate le Liner Wear

Ho thatafala ha thepa ea lijo ho ama ka ho toba lebelo la ho roala ha lipoleiti tsa mohlahare le li-liner. Majoe a thata, joalo ka granite kapa quartzite, a hloka matla a mangata ho robeha. Matla ana a ntseng a eketseha a lebisa khatellong e phahameng holim'a libaka tsa ho kopana tsa sefate sa mohlahare. Ha nako e ntse e ea, litlamorao tse pheta-phetoang tse tsoang ho lisebelisoa tse thata li etsa hore ho be le ho seha lichesele, tse hlahang e le mengoapo e tebileng, li-grooves le likoti holim'a lipoleiti tsa mohlahare. Hangata li-operators li hlokomela hore libaka tse pshatlehang li na le ts'ebetso e matla ka ho fetisisa, haholo-holo ha ho etsoa li-ores tse thata haholo.

Ho felloa ke mokhathala ho boetse ho hlaha ha lipoleiti tsa mohlahare li tobane le khatello e pheta-phetoang le meroalo ea tšusumetso. Mapetso a theha le ho ata, 'me qetellong a baka ho robeha ha brittle. Sebaka sa ho fepa, moo majoe a qalang ho kena ka har'a mochine o senyang, haholo-holo a kotsing ea mofuta ona oa tšenyo.Lipoleiti tsa mohlahare tse phahameng tsa manganesee ka hanela tse ling tsa liaparo tsena hobane li sebetsa ka thata nakong ea ts'ebetso, empa le lisebelisoa tsena li na le meeli ha li pepesetsoa lijo tse thata haholo.

Keletso: Ho lekola khafetsa ho thatafala ha thepa e kenang ho thusa basebelisi ho fetola litlhophiso tsa crusher le ho khetha lisebelisoa tse nepahetseng tsa liner, ho fokotsa nako e sa lebelloang ea ho theoha.

Liminerale tsa Abrasive le Ho Senya ha Bokahohle

Liminerale tse senyang lijong, joalo ka quartz kapa silika, li potlakisa ho senyeha ha bokaholimo ba metsi.dikarolo tsa mohlahare. Liteko tsa laboratori tsa abrasion, ho kenyeletsoa le liteko tsa gouging abrasion, li bonts'a kamano e matla le lipaterone tsa 'nete tsa lefatše. Liteko tsena li senola hore liminerale tse chefo li baka microploughing, microcutting le microcracking holim'a lipoleiti tsa mohlahare le liner. Ha likaroloana tsa abrasive li thella le ho hatella tšepe, li tlosa likaroloana tse nyenyane, tse lebisang ho lahleheloa ke molumo le libaka tse thata.

Liphuputso tsa masimong li tiisa hore boteng ba liminerale tse senyang bo eketsa sekhahla sa ho roaloa ha bokaholimo. Mekhoa e meholo ea ho apara e kenyelletsa:

- Abrasion e nang le khatello e tlase ea khatello ea maikutlo:E etsahala ha likaroloana li thella holim'a metsi ntle le khatello e ngata.

- Abrasion ea ho sila ka khatello e phahameng:E etsahala ha likaroloana tse nyane li sila khahlano le bokaholimo tlasa khatello.

- Gouging abrasion:Liphetho ho tsoa ho likaroloana tse kholo, tse thata tse amang le ho hatella lipoleiti tsa mohlahare.

Tafole e ka tlase e akaretsa mekhoa e tloaelehileng ea ho apara le lisosa tsa eona:

| Mofuta oa Paterone ea Apara | Tlhaloso | Sesosa/ Mabaka a susumetsang | Sebaka sa Jaw Plate | Litšobotsi tsa Matla |

|---|---|---|---|---|

| Seaparo sa ho Seha Chisel | Mekhoro e tebileng, li-grooves le mekoti | Tšusumetso e pheta-phetoang le extrusion ka ores | Libaka tsa ho pshatla (M, ML, L) | Tangential e phahameng, e itekanetseng |

| Fatigue Wear | Mapetso le brittle fracture | Tšusumetso e phetoang nako e telele | Sebaka sa ho fepa (H) | E phahameng e tloaelehileng, tangential e tlase |

| Abrasive Wear | Ho ngoapa, ho sila, ho khoapha | Boholo ba likaroloana, ho thatafala, ho hatella / ho kuta | Libaka tsa ho pshatla (M, ML, L) | Phahameng e tloaelehileng le tangential |

| Corrosion Wear | Oxidation ka lebaka la mongobo | Mongobo ka hara phepelo | Libaka tsohle | Ho roala lik'hemik'hale |

Lintho tse bonahalang tse kang ho thatafala, ho tiea, le microstructure le tsona li susumetsa tsela eo likarolo tsa mohlahare li hananang le ho rohakana. Liphetoho tsa geometry ea liner ho tloha moaparong li ka ama ts'ebetso ea crusher, ho etsa hore tlhahlobo e tloaelehileng e be ea bohlokoa.

Tšusumetso e Fetileng ea Liphepelo le Lichelete

Kabo ea boholo ba lijo e bapala karolo e kholo ho li-jaw plate le liner wear. Majoe a maholohali a etsa libaka tse nang le tšusumetso e matla holim'a lipoleiti tsa mohlahare. Litšusumetso tsena li baka ho senyeha ho sa lekanang, 'me libaka tse ling li senyeha ka potlako ho feta tse ling. Ha likaroloana tse kholo li kena ka har'a crusher, li ka boela tsa baka ho senya, ho lebisang ho li-grooves tse tebileng le likoting.

Litefiso tse fetelletseng lijong li hlahisa phephetso e fapaneng. Likaroloana tse ntle li ka tlatsa likheo pakeng tsa mafika a maholo, ho eketsa kotsi ea ho thibela. Li-blockages tsena li qobella mochini o silafatsang ho sebetsa ka thata, ho phahamisa mocheso le khatello ea maikutlo likarolong tse senyehileng. Ha nako e ntse e ea, sena se ka potlakisa ho roala le ho khathala, haholo-holo haeba likotlo li na le liminerale tse senyang.

Basebelisi ba ka laola likotsi tsena ka:

- Ho hlahloba lisebelisoa tsa ho fepa ho tlosa likotlo tse feteletseng pele li kena ka har'a crusher.

- Ho fetola maemo a koetsoeng (CSS) ho laola boholo ba thepa e fetang.

- Ho beha leihlo karolo ea majoe a maholohali le ho lokisa tlhophiso ea phepelo.

Tlhokomeliso: Liphepelo tse sa fetoheng le likahare tsa likotlo tse laoloang li thusa ho boloka esita le ho roala lipoleiti tsa mohlahareng, ho ntlafatsa ts'ebetso le nako ea bophelo ea mochini o pshatlang mohlahareng.

Mekhoa ea ho Apara e Amanang le Mongobo

Mongobo o ka har'a lisebelisoa tsa phepelo o ka fetola tsela eo likarolo tsa "crusher" li aparang ka eona nakong ea ts'ebetso. Metsi a sebetsa joalo ka setlolo le sets'oants'o sa ho roala, ho ipapisitse le maemo a ka har'a sesebelisoa. Hangata ba sebetsang ba bona mekhoa e fapaneng ea ho apara ha ba sebetsana le lisebelisoa tse metsi kapa tse khomarelang ha li bapisoa le majoe a omileng, a sa lefelloeng.

Liphello Tse Otlolohileng tsa Mongobo ho Wear:

- Metsi a ka etsa filimi e tšesaane pakeng tsa lejoe le letlapa la mohlahare. Ka linako tse ling filimi ena e fokotsa likhohlano, e leng se fokotsang ho roala ha letlalo.

- Maemong a mangata, mongobo o kopana le likaroloana tse ntle le letsopa. Motsoako ona o etsa sekhomaretsi se khomarelang se khomarelang lipoleiti tsa mohlahare le liner.

- Lintho tse khomarelang li baka "pancaking," moo likotlo tse metsi li bokellanang holim'a holim'a li-crusher. Likarolo tsena li tšoasa likaroloana tsa abrasive le ho eketsa ts'ebetso ea ho sila khahlano le tšepe.

Liphello tse sa Tobang le Tšenyo ea Bobeli:

- Mongobo o khothalletsa ho bola, haholo ha o kopantsoe le liminerale tse arabelang ka metsi. Corrosion e fokolisa bokaholimo ba lipoleiti tsa mehlahare le li-liner, e leng ho etsang hore li be kotsing ea ho roaloa ke mechine.

- Lijo tse nang le metsi hangata li lebisa ho blockages. Ha crusher e jara, mochini o tlameha ho sebetsa ka thata ho tlosa tšitiso. Matla ana a eketsehileng a eketsa khatello ea kelello likarolong tse apereng.

- Mongobo o phahameng o ka baka ho se lekane. Libaka tse ling tsa poleiti ea mohlahare li ka 'na tsa lula li koahetsoe ke lintho tse metsi, ha tse ling li lula li pepesitsoe. Phapang ena e lebisa mekhoeng ea ho roala li-patchy le ho fokotsa nako eohle ea bophelo ea likarolo.

Hlokomela:Basebelisi ba lokela ho beha leihlo boemo ba mongobo le mofuta oa likotlo phepelong. Lisebelisoa tse nang le letsopa tse nang le metsi a mangata li baka ho senyeha ho matla ho feta lehlabathe le hloekileng, le metsi.

Mekhoa e Tloaelehileng e Amanang le Mongobo:

| Mokhoa | Tlhaloso | Sephetho se Tloaelehileng |

|---|---|---|

| Phello ea Lubrication | Filimi ea metsi e fokotsa likhohlano | Ho roala butle butle |

| Pancaking/ Ho haha | Likotlo tse khomarelang li khomarela bokaholimo | Keketseho ea ho sila le ho senyeha |

| Seaparo se Senyang | Metsi le liminerale li baka liphetoho tsa lik'hemik'hale | Rust, pitting, tahlehelo ea bokaholimo |

| Khatello e Bakiloeng ke Thibelo | Lintho tse metsi li koala crusher, li phahamisa mojaro | Mokhathala o potlakileng le ho khathala |

| E sa Lekaneng Apara Mekhoa | Mongobo o sireletsa libaka tse ling, o pepesa tse ling | Moaparo o mobe, o sa lebelloang |

Mehato e Sebetsang ea ho Laola Liaparo Tse Amanang le Mongobo:

- Basebelisi ba ka sebelisa lisebelisoa tsa pele ho skrine ho tlosa likotlo tse feteletseng le letsopa pele ba li sila.

- Ho kenya li-sensor tsa mongobo ho thusa ho latela liphetoho maemong a fepa.

- Ho sebelisa li-anti-stick kapa lirafshoa holim'a li-chute le holim'a li-crusher ho fokotsa ho bokellana ha thepa.

- Ho hloekisa kamehla le ho hlahloba ho thibela tšenyo ea nako e telele ho senya le ho thibela.

Keletso:Basebelisi ba laolang mongobo le likotlo lijong ba ka lelefatsa bophelo ba likarolo tsa seroala sa mohlahare le ho fokotsa nako e sa reroang.

Mekhoa ea ho apara e amanang le mongobo e fana ka mathata a ikhethang ho pshatlang ha indasteri. Ka ho utloisisa litlamorao tsena, basebelisi ba ka etsa liqeto tse betere mabapi le phepelo ea phepelo, litlhophiso tsa li-crusher, le linako tsa tlhokomelo. Tsebo ena e lebisa ho nako e telele ea bophelo le ts'ebetso e tšepahalang ea crusher.

Lithuto tsa Litaba tsa Indasteri: Ts'ebetso ea Mochini oa Jaw Crusher

Ts'ebetso ea Ore e thata haholo

Hangata mesebetsi ea merafo e sebetsana le li-ores tse thata haholo, tse kang granite kapa quartzite. Lisebelisoa tsena li beha khatello e feteletseng likarolong tsa sefate sa mohlahare. Basebelisi ba hlokomela hore lipoleiti tsa mohlahare le li-liner li tsofala kapele ha li pshatla majoe ana a thata. Lipoleiti tse phahameng tsa tšepe tsa manganese li thusa ho hanela ho apara hona hobane li ba thata le ho feta nakong ea tšebeliso. Sebakeng se seng sa merafo, basebetsi ba ile ba fetohela ho lipoleiti tsa mohlahare tse tloaelehileng tse nang le boemo bo khethehileng ba leino. Phetoho ena e ntlafalitse bophelo ba ho apara le ho fokotsa palo ea li- shutdown bakeng sa tlhokomelo. Ho hlahlojoa khafetsa le ho nkeloa sebaka ka nako ea likarolo tse senyehileng li ile tsa boloka tšilafalo e sebetsa hantle. Basebelisi le bona ba ile ba lokisa tlhophiso ea phepelo ho qoba ho tlatsa mochini.

Tlhahiso ea Abrasive Aggregate

Tlhahiso ea abrasive aggregate, joalo ka ho pshatla basalt kapa lehlohlojane le nang le quartz e ngata, e etsa hore ho be le tikoloho e thata bakeng sa likarolo tsa mohlahare. Basebelisi ba bona matla a phahameng a abrasion le tšusumetso maemong ana. Ba sebelisa lisebelisoa tsa boleng bo holimo joalo ka tšepe ea manganese bakeng sa lipoleiti tsa mohlahare ka lebaka la thepa ea eona e thatafatsang mosebetsi. Sebopeho le boemo ba meno ba lipoleiti li phetha karolo ea bohlokoa ho laola ho apara. Ho etsa likarolo tsa moaparo bakeng sa kakaretso e ikhethileng ho thusa ho tsamaisa liaparo ka mokhoa o ts'oanang le ho eketsa ts'ebetso. Basebelisi libakeng tsena ba latela kemiso e tiileng ea tlhokomelo. Ba fetola likarolo ka nako e nepahetseng ho thibela ho hlōleha ho sa lebelloang.

- Likarolo tsa li-crusher tsa mohlahare li tobane le ho hohla ho hoholo le matla a matla tlhahisong e kopaneng ea abrasive.

- Lisebelisoa tsa boleng bo holimo le meralo e tloahelehileng li thusa ho hana ho khathala le ho ntlafatsa ts'ebetso.

- Nako ea tlhokomelo e bohlokoa bakeng sa ho ntlafatsa bophelo ba ho apara.

Tafole e ka tlase e akaretsa liphapang lipakeng tsa li-abrasive le tse fokolang haholo:

| Mofuta oa Kopo | Reka ea ho Apara | Boitsebiso bo Sebelisitsoeng | Litlhoko tsa Tlhokomelo |

|---|---|---|---|

| Abrasive Aggregate | Phahameng | Tšepe ea Manganese | Khafetsa, Tse Reriloeng |

| Hase Abrasive | Tlase | Lisebelisoa tse tloaelehileng | Hanyane Khafetsa |

Feed Feed Size ho Lits'ebetso tsa ho Recycle

Mesebetsi ea ho tsosolosa hangata e sebetsana le thepa ea phepelo e fapaneng ka boholo le sebopeho. Phapang ena e ama ts'ebetso ea mochini oa crusher le karolo ea bophelo bo bolelele. Ka linako tse ling basebelisi ba bona ho thijoa kapa ho emisoa ha mochini ha fepa e na le likotoana tse kholo kapa tse sa tloaelehang. Ho falla ha mohlahare oa crusher ho fetoha le bophahamo ba phepo, e leng se amang ts'ebetso e ntle. Pele o khetha mochini o silafatsang mohlahare bakeng sa ho sebelisoa hape, basebelisi ba sekaseka litšobotsi tsa thepa le boholo bo lebelletsoeng ba fepa. Tšebeliso ea matla e boetse e itšetlehile ka matla a thepa le boholo ba lesoba la crusher. Ho sila konkreite e matla haholo ho sebelisa matla a mangata ho feta lisebelisoa tse bonolo. Mekhabiso e menyenyane ea lesoba le eona e eketsa tšebeliso ea matla. Lintlha tsena li bonts'a hore boholo bo fapaneng ba phepelo le thepa ea thepa e bapala karolo e kholo ts'ebetsong ea crusher le bophelo ba karolo ea bophelo.

Basebelisi ba hlokomelang boholo ba phepelo le ho lokisa litlhophiso tsa crusher ba ka fokotsa ho khathala le ho ntlafatsa ts'ebetso ea ts'ebeliso ea lisebelisoa.

Ho lekola le ho Fokotsa ho Apare ha Mochini oa Jaw Crusher

Ho khetha Jaw Plate le Liner Materials

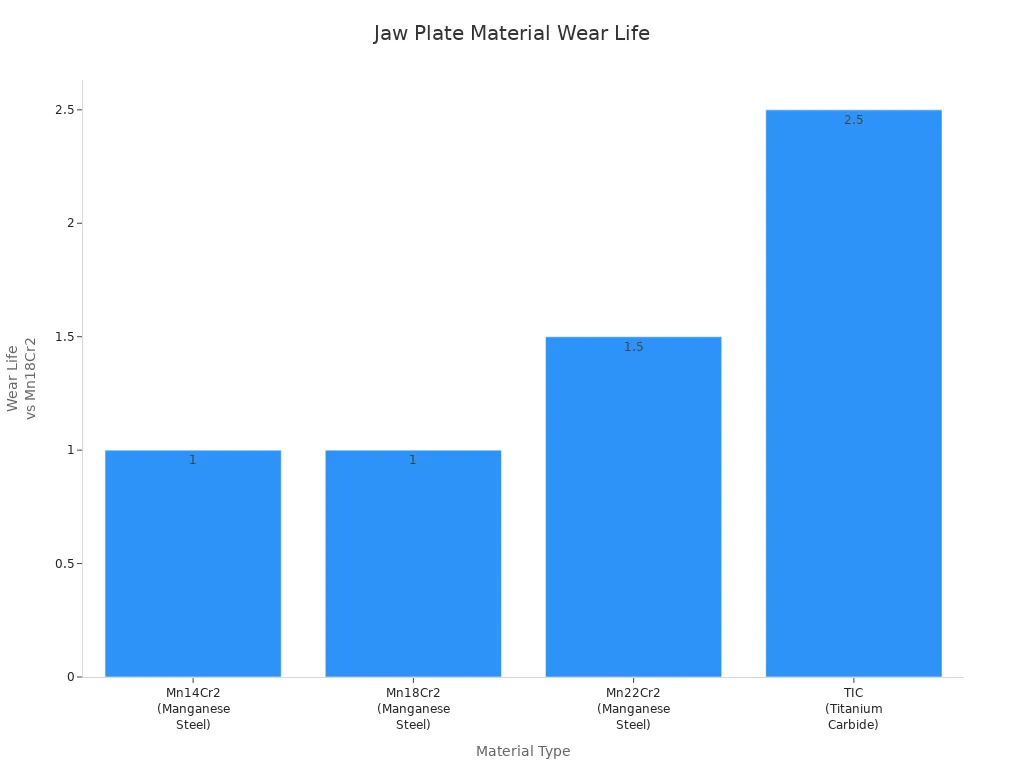

Ho khetha se nepahetsengpoleiti ea mohlahare le lisebelisoa tsa linere bohlokoa bakeng sa ho fokotsa ts'ebetso ea li-crusher tsa indasteri. Hangata li-operators li khetha limaraka tsa tšepe tsa manganese tse ipapisitseng le ho thatafala le ho hlaba ha lijo. Tafole e ka tlase e bapisa lisebelisoa tse tloaelehileng le ts'ebetso ea tsona:

| Mofuta oa Boitsebiso | Thepa ea Bohlokoa | Ho Lokeloa Bakeng sa Lisebelisoa tse Thata / Abrasive | Life Life Ha li Bapisoa le Mn18Cr2 |

|---|---|---|---|

| Mn14Cr2 | Matla a matla a phahameng, ho hanyetsa abrasion | Majoe a bonolo kapa a sa koaeheng | Baseline |

| Mn18Cr2 | Ho sebetsa ka thata-thata, ho hanyetsa abrasion | Majoe a mahareng ho isa ho a thata, a sa qhekellang | Baseline |

| Mn22Cr2 | Khanyetso e phahameng ea abrasion, nako e telele ea ho apara | Majoe a thata le a hlabang | Nako e telele ho feta Mn18Cr2 |

| Lisebelisoa tsa TIC | Bongata bo phahameng haholo, ha bo na tšusumetso | Lisebelisoa tse thata haholo le tse senyang | 1.5 ho isa ho 2.5 linako tse telele ho feta Mn18Cr2 |

Basebelisi ba sebetsanang le thepa ea phepelo e thata kapa ea abrasive hangata ba khetha Mn22Cr2 kapa lipoleiti tse kenyang TIC bakeng sa bophelo bo bolelele le nako e fokotsehileng.

Ho fetola Litlhophiso tsa Crusher le Litokisetso tsa Feed

Litlhophiso tse nepahetseng tsa crusher le litokisetso tsa phepo li thusa ho lelefatsa bophelo ba lipoleiti tsa mohlahare le li-liner. Basebelisi ba sebelisa mekhoa e mengata:

- Ho fepa ka har'a mohala ho tsamaisana le sekheo sa ho senya, ho fokotsa ho koala le ho apara ka tsela e sa tšoaneng.

- Ho fepa ka choke ho boloka phaposi bonyane e tletse 80%, e khothalletsa ho apara junifomo le ho silakanya hantle.

- Ho hlahloba esale pele ho tlosa likotlo le thepa e ngata ho feta tekano, ho thibela ho thibela le ho apara ka tsela e sa tšoaneng.

- Lijo tse hlophisitsoeng hantle li etsa bonnete ba hore li sebetsa ka mokhoa o tsitsitseng 'me li fokotsa ho apara sebakeng sa heno.

- Ho fokotsa lintho tsa tšepe ka har'a phepelo ho sireletsa likaroloana hore li se ke tsa senyeha.

Ho lokisa boemo ba lehlakore le koalehileng ho boetse ho laola sekhahla sa nip le katleho ea ho senya. Ho fepa ka mokhoa o tsitsitseng le litlhophiso tse nepahetseng li boloka litekanyetso tsa ho apara tse tšoanang le ho ntlafatsa bophelo bo bolelele ba Jaw Crusher Machine.

Maano a Tlhokomelo le Tlhokomelo ea Liaparo

Mekhoa e metle ea tlhokomelo e fokotsa ho roala le ho thibela ho hlōleha ho sa lebelloang. Basebelisi ba itšetlehile ka:

- Tlhokomelo e thibelang, e kenyelletsang litlhahlobo tse reriloeng le tse ling tse ncha pele ho hloleha ho etsahala.

- Tlhokomelo ea esale pele, ho sebelisa li-sensor le lisebelisoa tsa ho beha leihlo ho bona maemo a sa tloaelehang kapele le ho rera tokiso ka nako.

- Sistimi e tsoetseng pele ea ho beha leihlo, joalo ka li-sensor tsa ultrasonic le telematics, e fana ka data ea nako ea nnete mabapi le maemo a phepelo le boemo ba lisebelisoa.

Basebelisi ba sebelisa mekhoa ena ho lekola tsoelo-pele ea moaparo le ho fetola ts'ebetso ha ho hlokahala. Tlhokomelo ea nako ea 'nete le li-automation li thusa ho boloka phallo ea thepa e tsitsitseng, ho fokotsa ho tsofala, le ho ntlafatsa ts'ebetso ea li-crusher.

Keletso: Ho kopanya tokiso ea thibelo le e lebelloang le tekhenoloji ea morao-rao ea ho beha leihlo ho lebisa bophelong bo bolelele le ho koala ho sa reroang ho fokolang.

Mekhoa ea ho Predictive bakeng sa Karolo e Atolositsoeng ea Bophelo

Ts'ebetso ea sejoale-joale ea indasteri e ts'epahalla tlhokomelong e boletsoeng esale pele ho boloka metjhini e pshatlang mehlahare e sebetsa hantle. Mekhoa ea ho bolela esale pele e sebelisa theknoloji le ho beha leihlo khafetsa ho bona mathata pele a baka tšenyo. Li-operators li ka lelefatsa bophelo ba likarolo tsa sefate sa mohlahare ka ho latela mekhoa ena e bohlale:

- Kenya li-sensor ho lekola mocheso oa oli e tlotsang le boemo ba filthara. Ho lemoha liphetoho kapele ho bontša mathata a ka bang teng.

- Rulahanya litlhahlobo tsa letsatsi le letsatsi, beke le khoeli le khoeli u sebelisa manane a hlakileng. Ho hlahloba khafetsa ho thusa ho ts'oara pele ho matla.

- Khetha lipoleiti tsa mohlahare tse nang le lintho tse ngata tsa manganese, joalo ka ZGMn13. Lisebelisoa tsena li tšoarella nako e telele tlas'a maemo a thata.

- Tiisa liboutu le linate, 'me u bapise litlhōrō tsa meno le likhohlo. Kopano e nepahetseng e thibela ho apara ho sa tšoaneng le ho hlōleha ha karolo ea pele.

- Kenya lisebelisoa tse fokotsang ho thothomela 'me u laole sekhahla sa phepelo. Mehato ena e fokotsa khatello ea maikutlo holim'a crusher le ho liehisa ho apara.

Basebelisi ba sebelisang tlhokomelo e lekanyelitsoeng ba bona likotsi tse fokolang tse neng li sa lebelloa le bophelo ba nako e telele.

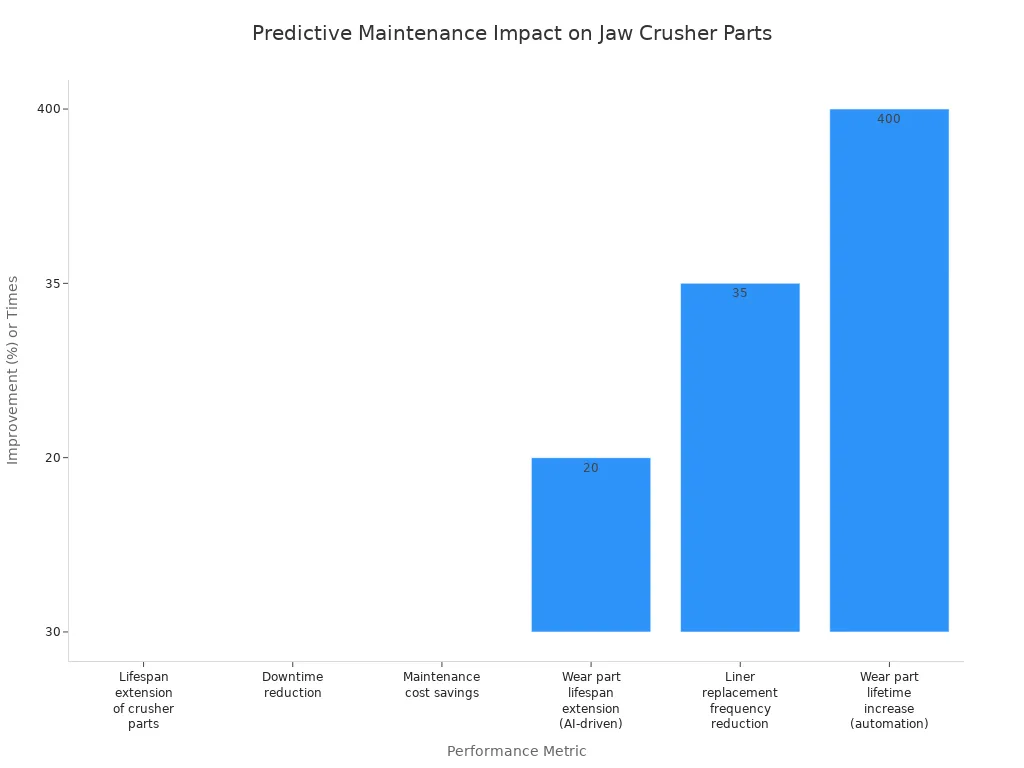

Lintlha tsa 'nete tsa lefats'e li bonts'a phello ea maano ana. Tafole e ka tlase e totobatsa lintlafatso tsa mantlha ho tsoa ho tokiso e boletsoeng esale pele:

| Metric ea Ts'ebetso | Lipalopalo tsa Ntlafatso | Tlhaloso ea Tšusumetso |

|---|---|---|

| Katoloso ea nako ea bophelo ea likarolo tsa crusher | Ho fihla ho 30% | Lisebelisoa tsa boleng bo holimo le tlhokomelo e boletsoeng esale pele li fokotsa ho nkeloa sebaka. |

| Phokotso ea nako ea ho phomola | Ho fihla ho 30% | Li-sensor tse bohlale le ho lemoha kapele li khaola libaka tse sa reroang. |

| Ho boloka litšenyehelo tsa tlhokomelo | Ho fihla ho 30% | Tlhokomelo e thehiloeng ho litlhoko e theola litšenyehelo. |

| Wear part lifespan extension (e tsamaisoa ke AI) | 15-20% | AI le automation li eketsa nako e telele. |

| Phokotso ea maqhubu a liner replacement | 35% | Lisebelisoa tsa ho bolela esale pele li bolela liphetoho tse fokolang tsa liner. |

| Keketseho ea nako ea bophelo bohle (automation) | 2 ho isa ho makhetlo a 4 | Ntlafatso ea othomathike e eketsa bophelo ba karolo e itseng haholo. |

Lits'ebetso tsa taolo ea li-crusher tse bohlale, joalo ka tse sebelisoang lits'ebetsong tse etelletseng pele, li ekelitse nako ea bophelo ka 15-20%. Liketsahalo tsa nako ea ho phomola li theohile ka 40%, 'me maqhubu a ho fetola liner a theohile ka 35%. Li-sensor tse latellang mocheso, ho thothomela, le ho roala li thusa basebelisi ho sebetsa pele ho hloleha ho etsahala. Phetoho ena ea ho tloha ho ts'ebetso ea ts'ebetso ho ea ho ts'ebetso e boletsoeng esale pele e boloka mechine e sebetsa nako e telele 'me e boloka chelete. Mekhoa e reriloeng esale pele e fa basebelisi taolo e eketsehileng le kholiseho ts'ebetsong ea bona ea setlolo sa mohlahare.

Mekhoa e Molemo ka ho Fetisisa ea ho Ntlafatsa Mochini oa Jaw Crusher Karolo ea Bophelo

Ho Matching Jaw Plate Material ho Fepa Litšobotsi

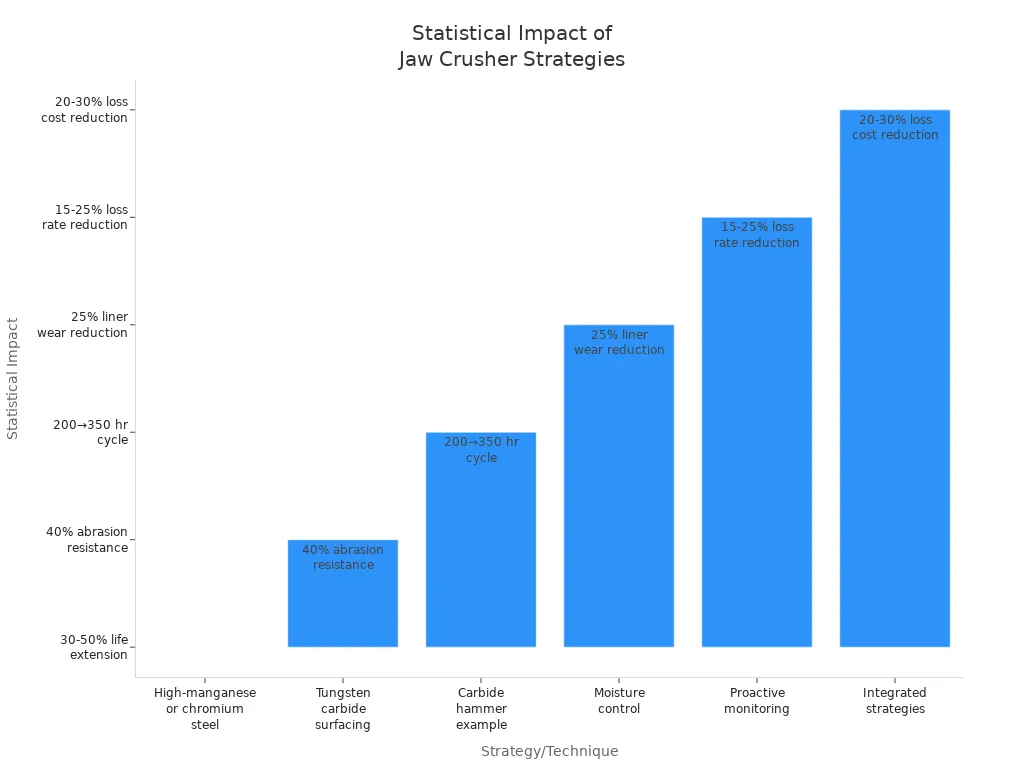

Ho bohlokoa ho khetha thepa e nepahetseng ea poleiti ea mohlahare le moralo bakeng sa ho holisa bophelo ba karolo ea crusher. Basebelisi ba tlameha ho:

- Khetha li-alloys tsa poleiti ea mohlahare tse thehiloeng holim'a lintho tse senyang. M1 alloy e sebetsa hantle bakeng sa lisebelisoa tse tlase tsa abrasion joalo ka lejoe la mokoetla. Li-alloys tsa pele tse kang M2, M7, M8, kapa M9 li molemo bakeng sa lisebelisoa tse hohlang haholo tse kang granite kapa tšepe ea tšepe.

- Bapisa mekhoa ea meno le fepa. Wide Teeth (WT) thusa ka lijo tse phahameng ka likotlo ka ho thibela ho paka. Meno a Sharp (ST) a ts'oara a boreleli kapa a likhutlo li fokotsa ho thella. Corrugated Corrugated (CC), Heavy Duty (HD), kapa Ultra-Thick (UT) plates e mamella lijo tse hlabosang.

- Latela likhothaletso tsa mohlala oa crusher. Mohlala, li-crushers tsa CJ615 hangata li sebelisa lipoleiti tsa Coarse Corrugated kapa Heavy Duty tse nang le alloy ea M8 bakeng sa fepa ea abrasive.

- Fetola lipoleiti tsa mohlahare nakong ea bophelo ba bona ho etsa bonnete ba hore li ntlafetse le ho boloka sebaka se setle ka ho fetisisa sa nip angle.

- Fetola litlhophiso tsa crusher, joalo ka litlhophiso tsa lehlakore tse koetsoeng le nip angle, ho tsamaisana le thepa ea phepelo.

Ho kopanya lisebelisoa tsa poleiti ea mohlahare le moralo ho fepa libopeho ho thusa ho ntlafatsa ts'ebetso le ho lelefatsa bophelo ba karolo.

Ho Hlahlobisisa Kamehla le ho Nchafatsoa ka Nako

Tlhahlobo ea kamehla le ho khutlisa likarolo tse tsofetseng ka potlako li boloka li-crushers li sebetsa hantle. Basebelisi ba rua molemo ho:

- Ho lemoha kapele ho senyeha ha nako ka ho hlahloba lipoleiti tsa mohlahare, li-bearings le likarolo tse ling.

- Ho nkeloa sebaka ka nako ea likarolo tse tsofetseng, tse thibelang tšenyo e eketsehileng le ho boloka katleho ea ho senya.

- Lubrication e nepahetseng ea likarolo tse tsamaeang, ho fokotsa likhohlano le ho lelefatsa bophelo ba mochini.

- Mekhoa ea ho beha leihlo e hlokomelisang basebetsi ka mathata, e tšehetsang tlhokomelo ea pele le ho fokotsa litšenyehelo tsa tokiso.

Kemiso e tsitsitseng ea tlhokomelo, ho kenyelletsa le tlhahlobo le ho nchafatsa karolo ka nako, e eketsa nako ea lisebelisoa le ho fokotsa litšenyehelo tsa ts'ebetso.

Koetliso ea Opereishene le Ntlafatso ea Ts'ebetso

Basebetsi ba koetlisitsoeng hantle le mekhoa e ntlafalitsoeng ba phetha karolo ea bohlokoa ho fokotsa ho apara. Basebelisi ba tlameha ho:

- Sebelisa maemo a nepahetseng a phepo le ho laola sekhahla sa phepelo ho matlafatsa bokhoni le ho fokotsa ho khathala.

- Fetola litlhophiso tsa crusher, joalo ka litlhophiso tse koetsoeng ka mahlakoreng, u sebelisa li-shim le bolelele ba toggle ho lefa bakeng sa ho khathala.

- Lekanya lekhalo lipakeng tsa mehlahare ho netefatsa litlhophiso tse nepahetseng.

- Etsa litokiso ha feela crusher e se na letho 'me e emisoa ho qoba ho roala pele ho nako.

- Itšetlehe ka litsamaiso tse itirisang tsa lubrication bakeng sa ho bea lubrication ka mokhoa o tsitsitseng.

- Utloisisa mekhoa ea ho fepa le mekhoa ea tlhokomelo ho fokotsa ho khathala le ho lelefatsa bophelo ba mochini.

Koetliso ea opereishene le ts'ebetso ea ts'ebetso e netefatsa ts'ebetso e tšepahalang le ho eketsa nako ea bophelo ea likarolo tsa crusher.

Fepa thepa ea thepa khanna litekanyetso tsa ho apara le bophelo ba tšebeletso bakeng salikarolo tse silafetsengmaemong a indasteri. Basebelisi ba sebelisang ts'ebetso ea ho beha leihlo, ba khethang lisebelisoa tse sa senyeheng, le ho lokisa ts'ebetso ba ka lelefatsa bophelo ba karolo ea 50% le ho fokotsa litšenyehelo tsa tlhokomelo. Litekanyetso tsa indasteri li bonts'a hore mekhoa e metle e theola litšenyehelo tsa ts'ebetso ka 10% -20% mme e eketsa nako ea bophelo ea lisebelisoa ka 15%. Lintlafatso tsena li lebisa tlhahisong e phahameng le poelo e matla matseteng.

LBH

Ke thepa efe ea phepelo e etsang hore poleiti ea mohlahare e apare ka potlako?

Ho thatafala le abrasiveness etsa hore ho apara ka potlako ka ho fetisisa. Majoe a thata joalo ka granite kapa liminerale tse nang le quartz li sila khahlano le lipoleiti tsa mohlahare. Basebelisi ba bona tse ling khafetsa ha ba sebetsana le lisebelisoa tsena.

Mongobo o ka har'a lisebelisoa tsa phepelo o ama likarolo tsa sehlahla sa mohlahare joang?

Mongobo o ka etsa hore motho a koalehe le ho apara ka tsela e sa tšoaneng. Lisebelisoa tse khomarelang, haholo-holo ka letsopa, li bokellana ka har'a sesilara. Kaho ena e eketsa khatello ea maikutlo likarolong 'me e ka baka ho apara ka potlako.

Na basebelisi ba ka fokotsa ho khathala ka ho fetola boholo ba fepelo?

Ee. Basebelisi ba laolang boholo ba lijo le ho tlosa majoe a maholo kapa likotlo li thusa ho tsamaisa liaparo ka ho lekana. Tloaelo ena e lelefatsa bophelo ba li-plate tsa mohlahare mme e ntlafatsa ts'ebetso ea li-crusher.

Ke lisebelisoa life tsa jaw plate tse sebetsang hantle bakeng sa phepelo ea mahlaba?

Manganese tšepee nang le chromium e phahameng kapa e kenngoeng ka TIC e hanela ho roala ho hoholo ka ho fetisisa. Lisebelisoa tsena li sebetsana le majoe a thata le a hlabang, a fanang ka bophelo bo bolelele ba tšebeletso.

Ke hangata hakae basebetsi ba lokelang ho hlahloba likarolo tsa seaparo sa crusher?

Basebelisi ba lokelahlahloba likarolo tsa moaparobeke le beke. Ho hlahloba khafetsa ho thusa ho bona matšoao a pele a tšenyo. Ho nkela sebaka ka nako ho thibela ho senyeha ho sa lebelloang mme ho boloka crusher e sebetsa hantle.

Nako ea poso: Jul-17-2025