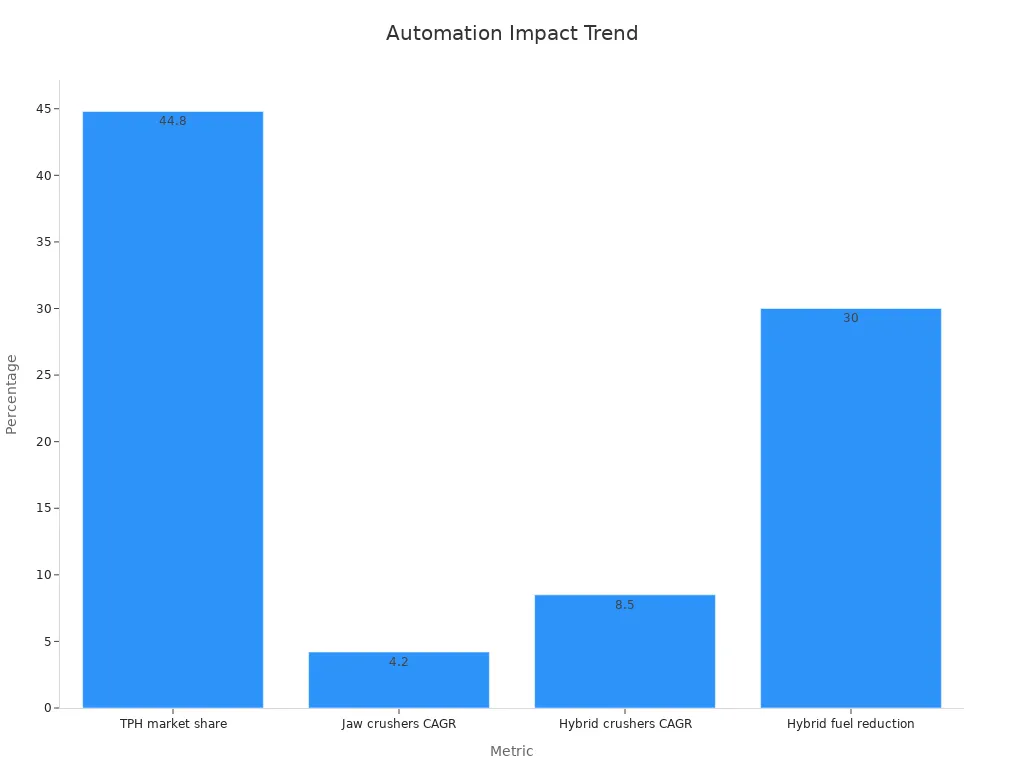

Theknoloji ea likarolo tsa Crusher e tsoela pele ho sutumelletsa meeli ka 2025. Hona joale lik'hamphani li sebelisa li-automation tse bohlale, thepa e sa senyeheng, le meralo e bolokang matla ho matlafatsa ts'ebetso le ho tšoarella. Mohlala, ts'ebeliso ea nako ea 'nete le litsamaiso tse nyalisitsoeng li thusa ho fokotsa nako le ho fokotsa tšebeliso ea matla ka 30%.

| Metric/Trend | Boleng/Palopalo | Kameho ho Ts'ebetso ea Crusher ka 2025 |

|---|---|---|

| Chelete e le 'ngoe ea toggle jaw crushers (2024) | USD 1.8 limilione tse likete | Ho laola 'maraka bakeng sa meralo e tsoetseng pele |

| 100–300 TPH karolo ea karolo ea matla (2024) | 44.8% | Optimised bokgoni ba mafura le automation |

| Li-crusher tsa Hybrid li boletse esale pele CAGR | 8.5% | Lintlafatso tsa matla a matla |

Basebelisi ba bona melemo ea 'nete ka bophelo bo bolelele ba ts'ebeletso bakeng salikarolo tsa li-crusher, litšenyehelo tse tlase bakeng sa mechini e silafatsang mohlahare, le likhetho tse feto-fetohang bakeng salikarolo tsa cone crusher, likarolo tsa crusher, leLikarolo tsa VSI crusher.

Lintlha tsa bohlokoa

- Li-sensor tse bohlale le li-automation li thusa ho bona mathata esale pele,fokotsa nako, le ho boloka chelete ho hlokomela tlhokomelo.

- Lisebelisoa tse tsoetseng pele le liaparoetsa hore likarolo tsa crusher li tšoarelle nako e telele, li sebetse hantle, 'me li theole litšenyehelo tsa ho nchafatsa.

- Meralo e baballang matla le litaolo tse fapaneng tsa lebelo li fokotsa tšebeliso ea matla le ho fokotsa litšenyehelo tsa ts'ebetso.

- Likarolo tsa modular le tsa mobile li lumella ho lokisoa kapele, ho ntlafatsa polokeho, le ho fana ka tharollo e bonolo bakeng sa mesebetsi e fapaneng.

- Lisebelisoa tsa AI le tsa dijithale li bolela esale pele ho hloleha, ho ntlafatsa ts'ebetso, le ho lelefatsa bophelo ba lisebelisoa, ho eketsa tlhahiso le ho fokotsa litšenyehelo.

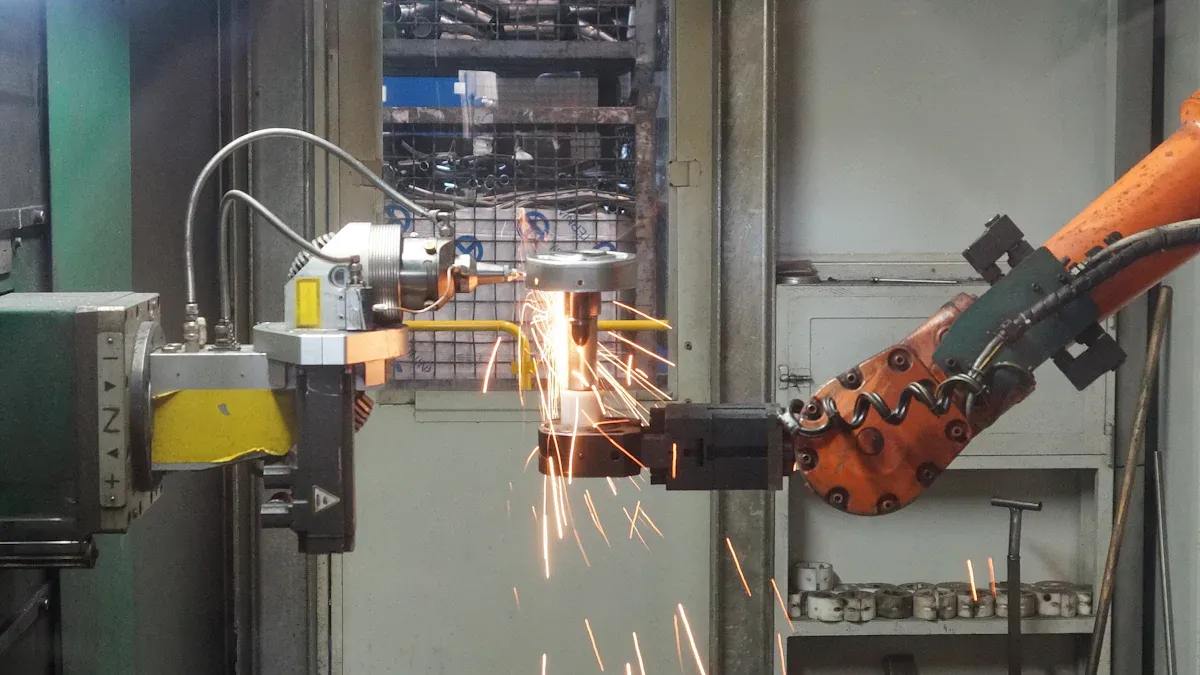

Smart Sensors le Automation likarolong tsa Crusher

Tlhokomelo ea Nako ea 'Nete le Tlhokomelo ea Pele

Li-sensor tse bohlale joale li bapala karolo e kholo ho li bolokalikarolo tse silafetsengho matha hantle. Li-sensor tsena li lekola bophelo ba lisebelisoa ka nako ea nnete. Basebelisi ba fumana lintlha tse mabapi le thempereichara, vibrate le moaparo. Sena se ba thusa ho bona mathata pele ba fetoha liphoso tse kholo. Sistimi ea ho lokisa esale pele e sebelisa li-analytics tsa data ho fumana liphoso esale pele. Sena se bolela hore lihlopha li ka lokisa mathata pele li baka nako.

- Sistimi ea othomathike ea lubrication e hlophisa nako ea ho tlotsa e ipapisitse le data ea nako ea nnete, e thusang ho thibela ho hloleha ho mamella.

- Li-sensor tsa ho lekola maemo li fana ka lintlafatso tsa bophelo, kahoo basebelisi ba ka nka khato kapele.

- Tlhokomelo ea esale pele e fetola tokiso ho tloha ho kemiso e behiloeng ho ea ho mokhoa o ipapisitseng le litlhoko, ho boloka nako le chelete.

- Tlhokomelo ea nako ea 'nete ea ho apara le meralo ea mafahla a dijithale e bolela esale pele ho apara ha lisebelisoa, ho fokotsa ho senyeha ho sa lebelloang.

- Mehlala ea ho ithuta e tebileng e ka bolela esale pele ho roaloa ha lisebelisoa ka ho nepahala ho phahameng, ho etsa hore tlhokomelo e be bohlale.

Lisebelisoa tsena tse bohlale li thusa lik'hamphani ho lelefatsa bophelo ba lisebelisoa le ho fokotsa litšenyehelo tsa tlhokomelo.

Litsamaiso tse Itokisang tsa Likarolo tsa Crusher

Automation ha e emise ho beha leihlo. Li-crushers tse ngata tsa sejoale-joale li sebelisa litsamaiso tse itokisang tsa boiketsetso. Sistimi ena e fetola litlhophiso joalo ka bophara ba lekhalo kapa sekhahla sa phepelo ntle le ho emisa mochini. Basebelisi ba ka etsa liphetoho ho tsoa ho phanele ea taolo kapa ba le hole. Sena se etsa hore sesebelisoa se sebetse hantle 'me se fokotsa tlhoko ea licheke tsa matsoho.

- Mohlala, Powerscreen Pulse, e fana ka leseli la nako ea nnete mabapi le boemo ba mochini, moaparo le litlhoko tsa tlhokomelo.

- Lintho tse kang GPS e phelang, tšebeliso ea mafura a mafura, le melaetsa ea liphoso li thusa basebelisi ho etsa liqeto kapele.

- Ho kena u le hole ho bolela hore lihlopha li khona ho beha leihlo le ho lokisa litlhophiso ho tsoa kae kapa kae.

Thuto-pale: Phokotso ea Nako ea ho Phokotsa ka Likarolo tsa Smart Crusher

Liphetho tsa 'nete tsa lefats'e li bonts'a matla a boiketsetso bo bohlale. Litemoso tse boletsoeng esale pele tsa tlhokomelo ea mochini oa Caterpillar li fokotsa nako ea ho theoha ka 30%. Likhamphani li bone keketseho ea 20% ts'ebetsong ea ts'ebetso mme li boloka ho fihla ho $500,000 selemo se seng le se seng. Li-dashboard tsa nako ea sebele li thusitse ho rera tokiso le ho boloka mechini e sebetsa nako e telele.

Li-sensor tse bohlale le li-automationthusa basebelisi ho qoba ho senyeha ho bitsang chelete e ngata le ho boloka likarolo tsa li-crusher li sebetsa ka thata nako e telele.

Lisebelisuoa tsa Boemo bo Hatetseng Pele tse Hanelang bakeng sa Likarolo tsa Crusher

Li-alloys le Likopano tsa Moloko o latelang

Li-alloys tse ncha le li-composite li ntse li fetoha hore na likarolo tsa crusher li nka nako e kae. Metal Matrix Composites (MMC) e hlahella hobane e ka tšoarella nako e telele ho isa ho makhetlo a mararo ho feta thepa ea khale. Likarolo tse ling, joalo ka Rock Box spider arm liner, joale li fana ka bophelo ba ho apara ka 300%. Sena se bolela ho fokotsa nako le ho fokotsa tse ling.Li-racks tse tsoetseng pele tsa concavee boetse e thusa ka ho khaola nako ea ho kenya ka halofo, e leng se etsang hore tlhokomelo e bolokehe le ho potlaka. Baenjiniere ba sebelisa 3D laser scanning ho latela moaparo le ho ntlafatsa sebopeho sa likamore tsa crusher. Sena se ka habeli bophelo ba ho apara ba likarolo tse ling. Lintlafatso tsena li etsa hore likarolo tsa crusher li be thata, li bolokehe, hape li ts'epahale.

- Teko ea ho apara masimong e beha lisebelisoa maemong a sebele a merafo, e fana ka liphetho tsa sebele tsa lefatše.

- Li-alloys tse fapaneng, joalo ka litšepe tsa k'habone le tšepe e tšoeu, li bonts'a phapang e kholo mabapi le hore na li hana ho apara hantle hakae.

- Thepa e betere e bolela litšenyehelo tse tlase bakeng sa ho nkela sebaka, ho sebetsa le ho lahleheloa ke tlhahiso.

- Ho etsa mohlala oa k'homphieutha ho thusa bo-rasaense ho qapa lisebelisoa tse thata le ho feta ka ho ithuta matla a tsona le hore na li robeha joang.

Liaparo tsa Ceramic le Polymer bakeng sa Likarolo tsa Crusher

Liaparo tsa ceramic le polymer li eketsa karolo e 'ngoe ea tšireletso. Liratsoana tsena li thusa likarolo tsa crusher hore li hanele mengoapo, mocheso le kutu. Liaparo tsa ceramic li thata haholo 'me li ka sebetsana le mesebetsi e thata, ha liphahlo tsa polymer li le bobebe' me li fokotsa likhohlano. Ka kopanelo, li thusa likarolo tsa crusher hore li tšoarelle nako e telele le ho sebetsa hantle. Liaparo tse ling tse ncha li bile li thusa ho boloka matla ka ho fokotsa matla a hlokahalang ho pshatla majoe. Sena se bolela hore mechini e sebelisa matla a fokolang 'me e lula e sebetsa nako e telele.

- Teko e khethehileng ea mofuta oa mohlahare e bonts'a hore moaparo le tšebeliso ea matla li amana haufi-ufi.

- Ho se sebetse hantle ho bolela hore matla a senyehileng a fokotsehile, kahoo li-crusher li sebetsa hantle haholoanyane.

Traditional vs. Advanced Crusher Parts Materials

| Metric | Advanced Crusher Liners (mohlala, Grade 846 manganese steel) | Li-Liner tsa Setso/Boleng bo Tlase |

|---|---|---|

| Apara Bophelo | Hoo e ka bang 2x ho feta | Baseline |

| Tšebetso ea ho Halakanya | 35% e betere | Baseline |

| Ntlafatso ea Phahamiso | Ee | No |

| Phokotso ea Draw ea Matla | Ee | No |

| Thepa ka Katleho | Ee | No |

Lisebelisoa tse tsoetseng pele joalo ka Kereiti ea 846 ea tšepe ea manganese e na le manganese le khabone e ngata. Tekano ena e ba fa boima bo betere le ho ba thata. Lisebelisoa tsa setso ha li tšoarelle nako e telele 'me li hloka ho nkeloa sebaka khafetsa. Likarolo tse ling tse tsoetseng pele, joalo ka polymer e matlafalitsoeng ka carbon fiber, li matla haholo empa li ka senyeha 'me tsa bitsa chelete e ngata. Hajoale, ho kopanya litšepe le li-composite ho fana ka litholoana tse ntle bakeng sa likarolo tsa crusher.

Ho khetha thepa e tsoetseng pele e sa senyeheng ho thusa lik'hamphani ho boloka chelete, ho fokotsa nako ea ho phomola, le ho fumana tse ling ho tsoa likarolong tsa tsona tsa crusher.

Lintlafatso tsa ho Sebelisa Matla ho Likarolo tsa Crusher

Meetso ea likarolo tsa Crusher e bolokang matla

Hona joale baetsi ba moralolikarolo tse silafetsengho boloka matla a mangata hofeta pele. Li-crusher tsa sejoale-joale li sebelisa likarolo tse kang li-drive frequency drive. Li-drive tsena li fetola lebelo ho latela hore na ke lintho tse kae tse hlokang ho hatelloa. Phetoho ena e bohlale e ka boloka hoo e ka bang 20% tšebelisong ea matla. Meetso e meng e mecha e bile e sebelisa li-magnetic levitation bearings. Li-bearings tsena li fokotsa tšebeliso ea matla ho fihla ho 30% mme li thusa likarolo tsa eona ho tšoarella nako e telele. Ha lik'hamphani li khetha mochine o nepahetseng bakeng sa mosebetsi, li qoba ho senya matla. Ho boloka boholo ba lijo bo tsitsitse le ho sebelisa likarolo tsa boleng bo holimo le hona hoa thusa. Ho hlahloba khafetsa li-bar, li-liner le mabanta ho boloka ntho e 'ngoe le e 'ngoe e tsamaea hantle le ka katleho.

Keletso: Ho sebelisa li-crushers tse nyalisitsoeng kapa tsa motlakase tse nang le li-automation tse bohlale ho ka fokotsa litefiso tsa mafura le motlakase le ho feta.

Li-Drives le Litaolo tse feto-fetohang likarolong tsa Crusher

Li-driable speed drives (VSDs) le litsamaiso tsa taolo li etsa phapang e kholo tseleng eo li-crushers li sebetsang ka eona. Li-VSD li lumella basebelisi ho laola lebelo la li-motor ka ho nepahala ho hoholo. Sena se bolela hore sesebelisoa se sebelisa matla a mangata kamoo se hlokang kateng. Ha mochine o qala, li-VSD li theola lebelo la motlakase, le sireletsang motlakase le ho boloka matla. Lisebelisoa tsena li boetse li thusa ho fokotsa ho senyeha ha likarolo le ho fokotsa litšila. Ka ho hokahanya li-VSD le lits'ebetso tse bohlale tsa taolo, lihlopha li ka shebella ts'ebeliso ea matla ka nako ea nnete le ho bona mathata afe kapa afe ka potlako. Sena se etsa hore crusher e sebetse hantle 'me e thusa ho qoba litokiso tse bitsang chelete e ngata.

Tšusumetso ea Litšenyehelo tsa Ts'ebetso ea Likarolo tsa Crusher tse Senyang Matla

Likarolo tsa crusher tse baballang matla li thusa lik'hamphani ho boloka chelete letsatsi le letsatsi. Setsing sa Clarabelle Mill, ho tsamaisa li-crusher ka mokhoa o felletseng oa moralo ho theola tšebeliso ea matla le ho fokotsa litšenyehelo tsa motlakase. Ha lisebelisoa li sebetsa hantle, ho na le likotlo tse fokolang tsa matla. Lik'hamphani tse sebelisang tlhokomelo ea pele li sebelisa 20-30% ka tlase ho litokiso. Ba boetse ba bona keketseho ea 10-20% ea hore na mechini ea bona e fumaneha hangata hakae. Tafole e ka tlase e bontša kamoo mekhoa e fapaneng ea ho boloka litšenyehelo e sebetsang kateng:

| Mokhoa oa ho Hlahloba Litšenyehelo | Tlhaloso |

|---|---|

| Tlhahlobo ea Litšenyehelo tsa Bophelo | E sheba litšenyehelo tsohle tsa bophelo ba lisebelisoa, ho kenyelletsa matla le tokiso. |

| Kakaretso ea Litšenyehelo Tsa Botho | E eketsa litšenyehelo tse tsitsitseng le tse feto-fetohang ho bona lipolokelo tsa nako e telele. |

| Tlhokomelo ea Pele | E fokotsa litšenyehelo tsa ho lokisa ka 30%. |

| Maintenance Optimized | E eketsa tšebeliso ea lisebelisoa le ho boloka chelete e ngata. |

Ho khetha likarolo tsa li-crusher tse baballang matla ho lebisa likolotong tse tlase, nako e tlase le ts'ebetso e ntle.

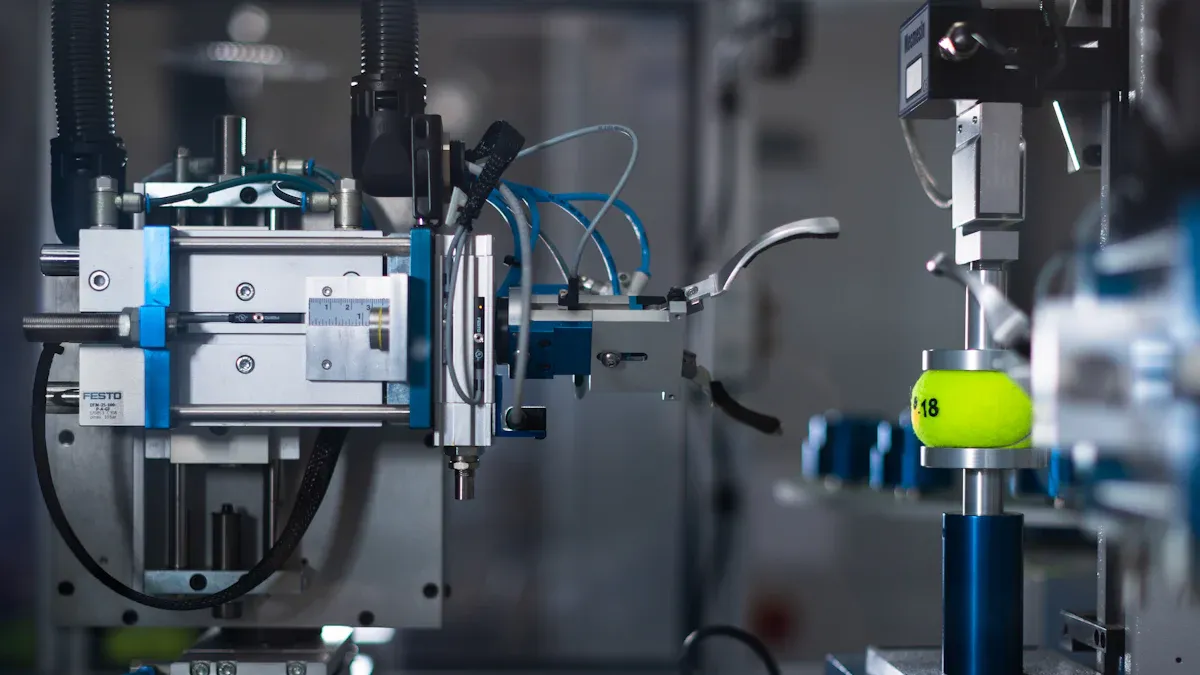

Litharollo tsa likarolo tsa Modular le Mobile Crusher

Likarolo tsa Crusher tse Fetohang ka Potlako

Litsamaiso tse fetohang ka potlako li fetotse tsela eo lihlopha li sebetsang ka eonatlhokomelo ea crusher. Litsamaiso tsena li lumella basebetsi ho fapanyetsana likarolo tse tsofetseng kapele, hangata ntle le lisebelisoa tse khethehileng. Moralo oa modular o bolela hore lihlopha li ka kopanya le ho bapisa li-crusher, li-skrini le li-conveyor ho lekana mosebetsi ka mong. Ho feto-fetoha ha maemo ho thusa lik'hamphani ho sebetsana le lisebelisoa tse fapaneng le litlhoko tsa sebaka habonolo. Likamore tsa ho senya tse nang le bokhoni bo phahameng li eketsa tlhahiso le ho fokotsa litšitiso. Boiketsetso le ho beha leihlo hole, joalo ka Pulse telematics, li boloka metjhini e sebetsa nako e telele ka ho hlokomelisa lihlopha ka mathata pele e ka ba mathata.

- Likarolo tsa modular li fokotsa nako ea ho phomola nakong ea tokiso.

- Lihlopha li ka etsa litlhophiso tsa projeke ka 'ngoe.

- Tšireletseho ea ntlafala hobane basebetsi ba qeta nako e nyane ba tšoara likarolo tse boima.

Keletso: Litsamaiso tsa modular li boetse li ts'ehetsa likarolo tsa motlakase tse baballang matla, tse thusang lik'hamphani ho fihlela litekanyetso tsa ho tsoa le lipheo tsa ts'ebetso.

Mobile Crusher Parts for Flexible Operations

Likarolo tsa mobile crusher li tlisa boemo bo bocha ba ho fetoha habonolo libakeng tsa mesebetsi. Likarolo tsena li hokahantsoe ka chassis e nang le mabili kapa e lateloang, kahoo lihlopha li ka li tsamaisa kapele ho tloha sebakeng se seng ho ea ho se seng. Hangata li-crushers tse tsamaeang li qala ho sebetsa nakong ea metsotso e 30 ho isa lihora tse 'maloa ka mor'a hore li fihle. Ho romelloa hona ka potlako ho boloka nako le chelete. Ho pshatla setšeng ho bolela ho fokotseha ha thepa e tala, e leng ho fokotsang litšenyehelo tsa lipalangoang le tšilafalo. Li-crushers tsa mehala li sebetsana le mefuta e mengata ea lisebelisoa, ho tloha merafong ho ea ho e sebelisoang hape, le ho ikamahanya le maemo a fetohang a sebaka.

| Sebopeho | Mobile Crusher | Crusher e tsitsitseng |

|---|---|---|

| Motsamao | E tsamaea habonolo lipakeng tsa libaka | E tsitsitse sebakeng se le seng |

| Nako ea Phano | Metsotso e 30 ho isa ho lihora | Ho hlokahala ho seta nako e telele |

| Bokhoni | 225-1000 lithane / hora | Ho fihla ho lithane tse 2000+ ka hora |

| Ho tenyetseha | Phahameng | Tlase |

| Litšenyehelo tsa Tlhokomelo | E phahameng | Tlase |

| Tšusumetso ea Tikoloho | Ho hlokahala lipalangoang tse fokolang | E hloka taolo ea lerole |

| Bolele ba bophelo | Khutšoane | Nako e telele |

Li-crushers tsa mobile li sebelisoamodular rotor le lisebelisoa tsa lisebelisoa. Lihlopha li ka fetola tsena bakeng sa lisebelisoa tse fapaneng, tse ntlafatsang ts'ebetso le ho lelefatsa bophelo ba karolo ea bophelo.

Phokotso ea Nako ea Tlhokomelo ka Likarolo tsa Modular Crusher

Likarolo tsa modular crusher li etsa hore tlhokomelo e potlake haholo. Lihlopha ha li sa hloka ho qeta lihora kapa matsatsi li lokisa. Sistimi ea phetoho e potlakileng e lumella basebetsi hore ba nke likarolo tse tsofetseng ka nako e khuts'oane, e leng se etsang hore mechini e sebetse. Mokhoa ona o boetse o fokotsa ts'ebetso ea matsoho, ho etsa hore ts'ebetso e bolokehe ebile e bonolo. Lik'hamphani li bona nako e fokolang le litšenyehelo tse tlaase tsa basebetsi. Lihlopheng tsa li-automation le tsa ho beha leihlo li le hōle li thusa ho rera ho lokisa pele ho senyeha.

- Ho fetola likarolo tse potlakileng ho bolela nako e eketsehileng.

- Mosebetsi o fokolang oa matsoho o ntlafatsa polokeho le ergonomics.

- Ho sebetsa setšeng ho fokotsa tieho ea lipalangoang le ho lokisa.

Likhamphani tse sebelisang litharollo tsa modular le tsa mehala li bona phaello ea 'nete tlhahisong, polokehong le ho boloka litšenyehelo.

Digitalization le Predictive Tlhokomelo bakeng sa likarolo Crusher

Litlhahlobo tsa Lintlha tsa Ts'ebetso ea Likarolo tsa Crusher

Hona joale li-analytics tsa data li thusa lik'hamphani ho rua molemo ka ho fetisisa lisebelisoa tsa tsona. Ka ho sebelisa lisebelisoa tsa dijithale, lihlopha li ka tseba hore na li-crusher li sebetsa joang ka nako ea nnete. Design of Experiments (DoE) e lumella baenjiniere ho leka litlhophiso tse fapaneng le ho bona hore na liphetoho li ama tlhahiso joang. Ba khona ho bona lipaterone tseo mekhoa ea khale e neng e se na tsona. Ka mohlala, ba ka bona kamoo lebelo le boholo ba lekhalo li sebetsang hammoho ho fetola tshebetso. Lihlopha li sebelisa lisampole tse khaotsoeng ka lebanta le tlhahlobo ea ts'ebetso ho bokella lintlha. Sena se ba thusa ho lokisa mechini bakeng sa liphetho tse ntle. Liteko tsa dijithale li etsa hore ho be bonolo ho rera le ho ntlafatsa tlhahiso.

- Baenjiniere ba sebelisa li-equation tsa tatellano ea pele le ea bobeli ho etsa mohlala oa ts'ebetso ea crusher.

- Tlhokomelo e tsoelang pele e thusa lihlopha ho fihlela maemo a lihlahisoa le litlhoko tsa 'maraka.

Li-Platform tsa Tlhokomelo e Lebeletsoeng bakeng sa Likarolo tsa Crusher

Li-platform tsa ho lokisa esale pele li sebelisa data ea nako ea nnete ho boloka mechini e sebetsa nako e telele. Nukon e hahile dashboard bakeng sa Newcrest Mining e bolelang esale pele hore na e tla nka sebaka nengliner. Sesebelisoa sena se sebelisa data e phelang le mehlala ea ho fokotsa maemo ho rera tlhokomelo. Lihlopha ha li sa hakanya nako ea ho lokisa likarolo. Ba fumana litemoso pele mathata a etsahala. Mokhoa ona o nka sebaka sa mekhoa ea khale, ea matsoho le ho etsa hore kemiso e be bonolo. Sephetho ke moralo o betere le li-crusher tse tšepahalang.

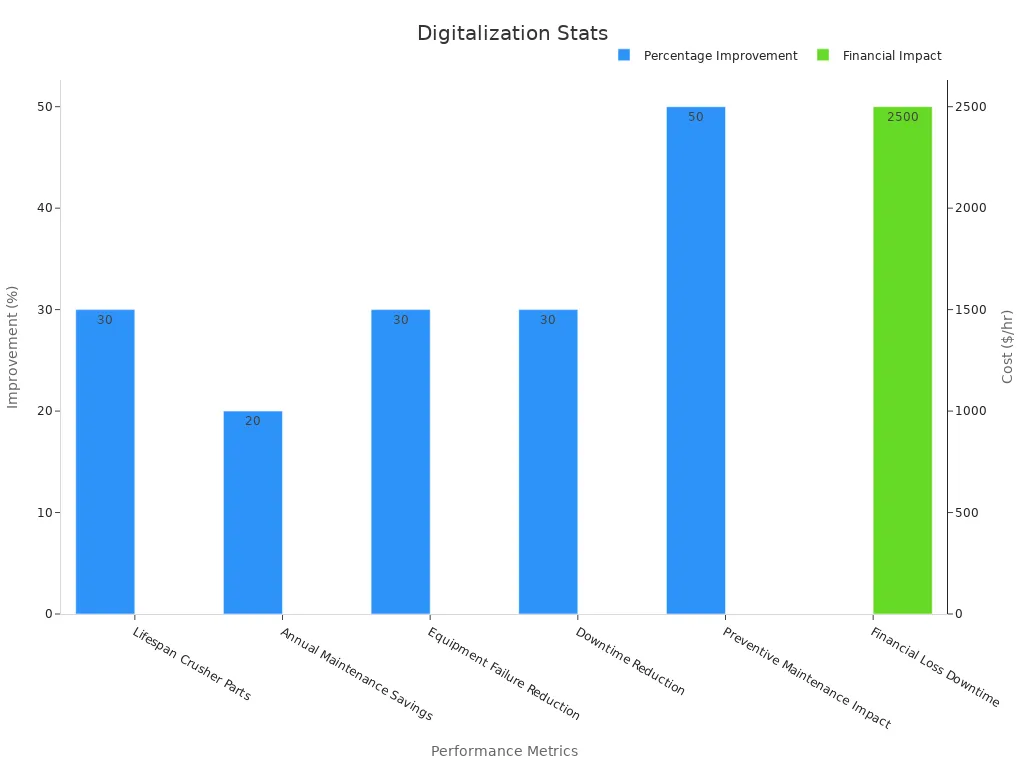

| Metric ea Ts'ebetso | Lipalopalo tsa Ntlafatso | Tlhaloso ea Tšusumetso |

|---|---|---|

| Katoloso ea nako ea bophelo ea likarolo tsa crusher | Ho fihla ho 30% | Ho sebelisa thepa ea boleng bo holimo ho eketsa nako ea bophelo, ho fokotsa makhetlo a mangata. |

| Ho boloka litšenyehelo tsa selemo le selemo | Ho fihla ho 20% | Likarolo tsa Premium le tlhokomelo e ntlafalitsoeng li fokotsa litšenyehelo tsa selemo le selemo tsa tlhokomelo. |

| Ho fokotseha ha monyetla oa ho hloleha ha lisebelisoa | Ho fihla ho 30% | Tlhokomelo e thibelang e fokotsa kotsi ea ho hlōleha, e ntlafatsa ts'ebetso ea ts'ebetso. |

| Phokotso ea nako ea ho phomola | Ho fihla ho 30% | Ho tsetela likarolong tsa premium ho fokotsa nako e sa reroang haholo. |

| Tahlehelo ea lichelete ho tsoa ho nako e sa reroang | Hoo e ka bang. $2,500 ka hora | E totobatsa phello ea litšenyehelo tsa nako ea ho theoha, e totobatsang boleng ba nako e ntlafetseng. |

| Tšusumetso e thibelang ea tlhokomelo ea ho hlōleha | Ho fihlela ho 50% phokotso | Tlhokomelo e reriloeng e fokotsa ho hloleha ha mochini, ho ntlafatsa ts'epo le nako. |

Tlhokomelo ea esale pele e thusa lihlopha ho qoba ho senyeha ha chelete e ngata 'me li boloka li-crusher li sebetsa ka hohle kamoo li ka khonang.

Ho Eketsa Bophelo ba Likarolo tsa Crusher ka Lisebelisoa tsa Dijithale

Lisebelisoa tsa dijithale li thusa ho lelefatsa bophelo ba likarolo tsa crusher. Software ea tlhokomelo e romela likhopotso le lirekoto tsa mabenkele. Sena se boloka litlhahlobo ka nako le ho thusa lihlopha ho lokisa mathata esale pele. Li-sensor tsa vibrate le mocheso li bona liboutu tse hlephileng kapa ho chesa haholo pele ho hloleha ho etsahala. Lits'ebetso tse itirisang tsa lubrication li fana ka mafura a lekaneng, li emisa ho fihla ho 75% ea ho hloleha ho jara. Lisebelisoa tsena li fokotsa nako ea ho theoha ho fihlela ho 30% le ho fokotsa litšenyehelo tsa tlhokomelo ka hoo e ka bang 30%. Ts'ebetso ea ho senya e ka nyoloha ka 15% ha lihlopha li sebelisa lisebelisoa tsa digital bakeng sa ho hlahloba kamehla. Likhamphani li bona bophelo bo bolelele ba lisebelisoa le lintho tse makatsang tse fokolang.

Digitalization e fa basebelisi taolo e eketsehileng, e boloka chelete, 'me e boloka li-crusher li sebetsa nako e telele.

Litloaelo tsa Likarolo tsa Crusher tse Sebeletsang Eco-friendly

Lisebelisuoa tsa likarolo tsa Crusher tse ka sebelisoang hape le tse nang le phello e tlase

Lik'hamphani tse ngata li khetha hona joalelisebelisoa tse tšehetsang melao-motheo ea 3R: Fokotsa, Sebelisa Hape, 'me u Boeletse Tšebeliso. Ba rala likarolo tsa crusher hore li tšoarelle nako e telele le hore li sebelisoe hape qetellong ea bophelo ba bona. Ka indasteri ea tšepe, theknoloji e ncha ea slag crusher e thusa ho fetola litšila hore e be lisebelisoa tsa bohlokoa. Mokhoa ona o fokotsa litšila tsa lithōle 'me o tšehetsa moruo o pota-potileng. Tlhahlobo ea bophelo bo botle e bonts'a hore ho sebelisa lisebelisoa tse tsosolositsoeng, joalo ka konkreite e tsoang litšila tsa kaho, ho theola khabone. Mekhoa ena e boetse e fokotsa tlhokahalo ea lisebelisoa tse ncha tse tala, tse thusang ho sireletsa mehloli ea tlhaho. Lihlopha tse shebaneng le ho sebelisoa hape le bophelo bo bolelele ba lihlahisoa li bona litšila tse fokolang le litšenyehelo tse tlase.

Tlhahiso e Hlollang ea Matla ea Likarolo tsa Crusher

Tlhahiso e baballang matla e ntse e fetola tsela eo likarolo tsa crusher li etsoang ka eona. Likhamphani li sebelisa li-automation le li-control tse bohlale ho fokotsa tšebeliso ea matla nakong ea tlhahiso. Lintlha tsa bohlokoa ke tsena:

- Tšebeliso e khethehileng ea matla bakeng sa ho senya e tloha ho 0.48 ho isa ho 1.32 kWh ka tonne.

- Ntlafatso ea lijo le boiketsetso bo ka fokotsa tšebeliso ea matla ka 10-30%.

- Meralo e mecha le likhoele li thusa ho fokotsa khohlano, ho boloka matla le ho feta.

- Ho ferekana le ho felloa ke matla ho baka tahlehelo e kholo ea matla, empa mahlale a macha a ka fokotsa sena ka 30% lilemong tse 20 tse tlang.

- Liphetoho tsena li ka boloka ho fihla ho 550 TWh ea matla le ho fokotsa lithane tse limilione tse 290 tsa CO2 selemo le selemo.

Ka ho etsa likarolo tsa li-crusher ka matla a fokolang, lik'hamphani li thusa polanete le ho boloka chelete.

Ho Latela Tikoloho ho Likarolo tsa Crusher Technology

Theknoloji ea sejoale-joale ea li-crusher e thusa lik'hamphani ho fihlela melao e thata ea tikoloho. Mokhoa ona ke ona:

- Hona joale li-crusher li fokotsa molumo oa likhahla, li etsa hore ho be bonolo ho li sebelisa hape li be bohlokoa haholoanyane.

- Mechini e tlosa ho fihla ho 98% ea lino tse sa lefelloeng matlapeng, ho khaola litšila tse kotsi.

- Litsamaiso tsa briquetter li fumana metsi a litšila, kahoo lik'hamphani li ka li sebelisa hape.

- Lisebelisoa tsa ho hloekisa metsi li sebelisa metsi hape, li fokotsa litšenyehelo tsa ho lahla le ho thusa ho finyella melao.

- Li-crusher tse tsamaeang ka motlakase le lisebelisoa tse thibelang lerole li fokotsa mesi le ho boloka moea o hloekile.

Lintlafatso tsena li thusa lik'hamphani ho latela melao ea tikoloho, ho fokotsa litšila, le ho tšehetsa bokamoso bo hloekileng.

Khokahano ea AI le ho Ithuta Mochini likarolong tsa Crusher

Polelo ea ho Hlōleha ka AI bakeng sa Likarolo tsa Crusher

Hona joale AI e thusa lihlopha ho bolela esale pele hore nalikarolo tse silafetsenge ka hloleha. Lisebelisoa tse bohlale li shebella matšoao a kang ho thothomela, mocheso, le liphetoho tsa khatello. Ba sebelisa lintlha tsena ho bona mathata pele a baka karohano. Ka mohlala, SBM's Smart Crusher Control System semeleng sa Canada ore ore e entse phapang e kholo. Sistimi e fetotse litlhophiso ka nako ea nnete le tlhokomelo e hlophisitsoeng pele ho hloleha ho etsahala. Sena se lebisitse ho keketseho ea 22% ea tlhahiso, 40% liketsahalo tse fokolang tsa nako, le 15% ea ho boloka matla. Basebelisi ba tšepa lisebelisoa tsena tsa AI ho boloka mechini e sebetsa nako e telele le ho qoba lintho tse makatsang tse bitsang chelete e ngata.

| Metric ea Ts'ebetso | Ntlafatso e Amahanngoa le Khokahano ea AI |

|---|---|

| Keketseho ea Phallo | Keketseho ea 22% (ho tloha ho 550 TPH ho isa ho 670 TPH) |

| Phokotso ea nako ea ho phomola | 40% liketsahalo tse fokolang tsa nako ea phomolo |

| Ho Boloka Matla | Phokotso ea 15% ea tšebeliso ea matla |

| Karolo ea Lifespan Extension | 15-20% nako e telele ea bophelo bakeng sa likarolo tsa ho roala |

| Liner Replacency Frequency | Phokotso ea 35% morafong oa chromite oa Turkey |

Polelo ea ho hloleha e tsamaisoang ke AI e bolela ho hakanya ho fokolang le nako e eketsehileng bakeng sa ts'ebetso e 'ngoe le e' ngoe.

Ntlafatso ea Ts'ebetso e Ikemetseng likarolong tsa Crusher

Ho ithuta ka mochini hona joale ho thusa li-crushers ho sebetsa ka bohlale, eseng ka thata ho feta. Litaolo tse itirisang li lokisa maemo a phepelo le litlhophiso ho boloka ts'ebetso e tsitsitse. Sena se bolela boholo bo tsitsitseng ba sehlahisoa le boleng bo betere. Lihlopha ha li sa hloka ho shebella lintlha tsohle. Sistimi e fumana tsela e molemohali ea ho tsamaisa li-crusher le ho bona litaba esale pele. Lintlha tsa nako ea nnete li thusa basebelisi ho etsa liqeto kapele. Tlhokomelo e fetoha ho tloha ho lokisa mathata ka mor'a hore ho etsahala hore e emise pele e qala.

| Metric e sebetsang hantle | Ntlafatso ea Tlhaloso |

|---|---|

| Tšebeliso ea Matla | Phokotso e fihlang ho 30% ho latela ts'ebeliso |

| Apara Karolo ea Bophelo Bohle | Keketseho e habeli ho isa ho hane ea nako ea bophelo bohle |

| Nako ea ho qetela | Nako e ekelitsoeng ka lebaka la liphetoho tse fokolang le ho emisa |

| Ho lumellana ha Sehlahisoa | Boholo ba sehlahisoa bo tsitsang ka lebaka la ho ikamahanya le maemo |

Ntlafatso e itirisang e thusa lihlopha ho matlafatsa ts'ebetso ntle le ho sebelisa chelete e ngata ho reka lisebelisoa tse ncha.

Bokhoni ba Bokamoso ba AI ho Crusher Parts Technology

Bokamoso bo shebahala bo khanya bakeng sa AI likarolong tsa crusher. Litsebi li lebeletse hore 'maraka oa crusher oa majoe o hōle ho tloha ho $ 5.2 limilione tse likete ka 2024 ho ea ho $ 8.3 limilione tse likete ka 2033. Boiketsetso bo tsamaisoang ke AI, tlhokomelo e boletsoeng esale pele, le ho shebella nako ea sebele ho tla khanna kholo ena. Lisebelisoa tse ncha joalo ka pono ea komporo le liroboto li tla thusa lihlopha ho sebetsa ka potlako le ka mokhoa o sireletsehileng. Ho ithuta ka mochini ho tla lula ho ntlafatsa tsela eo li-crushers li sebetsang ka eona, ho etsa hore li sebetse hantle le ho tšepahala.

- Mmaraka o ikemiselitse ho hola ho 6.2% CAGR ho tloha 2026 ho isa 2033.

- Ho kopanya AI ho tla boloka ho theola litšenyehelo le nako ea ho theoha.

- Likhamphani li tla sebelisa lintlha tse ngata ho etsa liqeto tse bohlale le ho lula pele.

Ha AI e ntse e tsoela pele ho fetoha, likarolo tsa crusher li tla tšoarella le ho feta, li sebetse hantle, 'me ho be bonolo ho li laola.

Theknoloji ea likarolo tsa li-crusher e ntse e tsoela pele. Hona joale lik'hamphani li sebelisa lisebelisoa tse bohlale, lisebelisoa tse betere, le meralo e baballang matla. Liphetoho tsena li thusa lihlopha ho sebetsa kapele le ho boloka chelete. Li boetse li etsa hore likarolo tse silafatsang li tšoarelle nako e telele le ho thusa polanete. Mang kapa mang ea batlang ho tsoela pele tšimong ena o lokela ho shebella mekhoa ena. Mehopolo e mecha likarolong tsa crusher e tla lula e theha indasteri ka lilemo tse tlang.

LBH

Melemo ea mantlha ea ho sebelisa likarolo tse bohlale tsa crusher ke efe?

Bohlalelikarolo tse silafetsengthusa lihlopha ho bona mathata esale pele. Ba fokotsa nako le ho boloka chelete ho lokisoa. Basebelisi ba fumana lintlafatso tsa nako ea nnete, kahoo ba ka lokisa litaba pele e ka ba mathata a maholo. Likarolo tsena li boetse li thusa mechini hore e tšoarelle nako e telele.

Lisebelisoa tse tsoetseng pele li ntlafatsa ts'ebetso ea karolo ea crusher joang?

Lisebelisoa tse tsoetseng pelejoalo ka li-alloys tse khethehileng le likoahelo li etsa hore likarolo tsa crusher li be thata. Ba hanela ho roala le mocheso ho feta lisebelisoa tsa khale. Sena se bolela hore likarolo li nka nako e telele 'me li hloka tse ling tse fokolang. Lihlopha li sebelisa nako le chelete e nyane ho hlokomela.

Na ho bonolo ho kenya likarolo tsa modular crusher?

Ee, likarolo tsa modular crusher li sebelisa sistimi e fetohang kapele. Basebetsi ba ka li fetola kapele, hangata ntle le lisebelisoa tse khethehileng. Sena se etsa hore ho kenngoe ho bolokehe le ho be bonolo. Lihlopha li qeta nako e nyane li lokisa le ho fumana mechini e sebetsang hape kapele.

Na likarolo tsa crusher tse bolokang tikoloho li bitsa ho feta?

Likarolo tsa li-crusher tse sebetsang hantle ka linako tse ling li bitsa chelete e ngata qalong. Ha nako e ntse e ea, ba boloka chelete ka ho tšoarella nako e telele le ho fokotsa litšila. Lik'hamphani tse ngata li fumana melemo ea nako e telele ea polokelo le ea tikoloho e lekanang le matsete.

Nako ea poso: Jun-14-2025