Sesepa sa mohlahare se sebetsa karolo ea bohlokoa phokotsong ea lintho tse bonahalang, ho pshatla mafika a maholo ka boholo bo bonyenyane, bo laolehang bakeng sa lits'ebetso tsa indasteri. E sebetsa ka ho sebelisa matla a khatello ho pshatla thepa pakeng tsa lipoleiti tse peli-e le 'ngoe e tsitsitseng le e tsamaeang-e tsamaisoang ke asefate sa mohlahare sa mohlahare. Mochine ona o netefatsa ts'ebetso e nepahetseng ea lisebelisoa tse tala, ho etsa hore li-crushers tsa mehlahare e be tsa bohlokoa indastering ea merafo, ea kaho le ea ho e sebelisa hape.

Litloaelo tsa bohlokoa li totobatsa bohlokoa ba tsona bo ntseng bo eketseha:

- Tlhokahalo e potlakileng ea liindasteri le kholo ea litoropo bakeng sa limela tsa li-jaw crusher.

- Li-crusher tsa mohlahare li nka sebaka sa mefuta ea setso bakeng sa tharollo ea setšeng.

- Liketso tse ntseng li eketseha tsa kaho linaheng tse ntseng li hōla moruong ntlafatso ea mekhoa ea motheo ea mafura.

Li-crushers tsa mehlahare le tsona li kenya letsoho ho tšoarella. Ba thusa ho tsosolosa konkreite le majoe, ho fokotsa litšila le ho sebelisa thepa hape mererong e mecha. Merafong, ba sebetsana le phokotso ea boholo ba mantlha kajaw plate for crusher, ho etsa bonnete ba hore ts'ebetso e theoha hantle. Ho feto-fetoha ha tsona le ho tšepahala, hammoho le tsa bohlokoadikarolo tsa mohlahare, li etse hore e be motheo oa tšebetso ea liindasteri, haholo-holo ka moralo o mocha oa polase ea mohlahare o matlafatsang tšebetso ea tsona.

Lintlha tsa bohlokoa

- Li-crushers tsa mehlahare li pshatla majoe a maholo hore e be a manyenyane. Li bohlokoa merafong, kahong, le ho e sebelisa hape.

- Sebaka sa ho pshatla se bōpehileng joaloka V se thusa ho pshatla majoe hantle le ka potlako.

- Ho hlahloba lipoleiti tsa mohlahare hangatae boloka mochini o sebetsang hantle mme o qoba ho lokisoa ho hoholo.

- Theknoloji e ncha e bohlalee tla etsa hore li-crushers tsa mohlahare li sebetse hantle le ho bitsa chelete e tlase.

- Meetso e bonolo ea tikoloho, joalo ka mehlala ea motlakase, e thusa ho sireletsa tikoloho.

Jaw Crusher ke eng?

Tlhaloso le Morero

Mohlahare oa mohlahare ke sesebelisoa sa mochini se etselitsoeng ho pshatla majoe a maholo le lisebelisoa ho etsa likotoana tse nyane, tse laolehang. E finyella sena ka ho sebelisa mehlahare e ’meli—o le mong o tsitsitseng le o mong o sisinyehang—a sebetsang hammoho ho pshatla thepa ka matla a ho hatella. Mohlahare o suthisoang o ntse o ea pele le morao, o etsisa ho sisinyeha ha nutcracker, ha mohlahare o tsitsitseng o ntse o eme. Ketso ena e pshatlehang e etsa hore li-crushers tsa mehlahare e be tse loketseng bakeng sa ho sebetsana le lisebelisoa tse thata le tse boreleli, tse kang ores le lithako tsa kaho.

Li-crushers tsa mehlahare hangata li sebelisoa e le li-crushers tsa mantlha indastering ea merafo, ea kaho le ea ho e sebelisa hape. Ho tšepahala ha bona le bokhoni ba bona ba ho sebetsana le lisebelisoa tse thata li etsa hore e be tsa bohlokoa haholo bakeng sa ho fokotsa thepa e tala hore e be boholo bo loketseng bakeng sa ts'ebetso e tsoelang pele.

Hlokomela:Li-crushers tsa mehlahare li bapala karolo ea bohlokoa lits'ebetsong tse tšoarellang ka ho thusa ho sebelisoa bocha ha thepa ea kaho, ho kenya letsoho moruong o potolohang.

Kakaretso ea Likaroloana tsa Bohlokoa

Li-crushers tsa mohlahare li na le tse 'maloalikarolo tsa bohlokoa tse sebetsang hammoho ho netefatsa ts'ebetso e sebetsang hantle. Likarolo tsena li kenyelletsa:

- Mehlahare:Mohlahare o tsitsitseng o lula o eme, ha mohlahare o suthang o silakanya thepa khahlanong le oona.

- Kamore ea ho Hlōla:Moralo o nang le sebopeho sa V o lumella lisebelisoa ho kena ka bophara holimo le ho tsoa li le moqotetsane ka tlase.

- Flywheel:E boloka matla ho boloka motsamao o bonolo le o tsoelang pele oa lipoleiti tsa mohlahare.

- Letlapa la Elbow:E monya meroalo le ho boloka lipoleiti tsa mohlahare li le maemong.

- Eccentric Shaft:E fetolela matla a motlakase motsamaong o fananang oa mohlahare o suthang.

| Sebopeho | Tlhaloso |

|---|---|

| Mehlahare | Mehlahare e tsitsitseng le e sisinyehang; mehlahare e tsitsitseng e eme ha mehlahare e suthang e pshatla lisebelisoa. |

| Mohaho oa ho pshatla | Moralo o nang le sebopeho sa V o lumellang thepa ho kena ka bophara le ho pshatleha pele e tsoa e patisane. |

| Flywheel | E boloka matla bakeng sa motsamao o boreleli le o tsoelang pele oa poleiti ea mohlahare. |

| Letlapa la Elbow | E boloka boemo ba poleiti ea mohlahare mme e monya meroalo ea tšusumetso. |

| Eccentric Shaft | E fetola matla a motlakase hore e be motsamao o fananang oa poleiti ea mohlahare e suthehang. |

| Bokhoni bo Phahameng | E fihlella bokhoni ba ho sebetsa ba lithane tse makholo ka hora ka molao-motheo oa extrusion crushing. |

| Ho feto-fetoha ha maemo | E khona ho sebetsana le ores e thata ho fihla ho 7 ka tekanyo ea boima ba Mohs ka lisebelisoa tse khethehileng tsa poleiti ea mohlahare. |

| Sebopeho se Bonolo | E entsoe ka likarolo tse 'ne tsa mantlha: foreimi, kopano ea mohlahare e suthehang, eccentric shaft, le poleiti ea setsoe. |

| Litsenyehelo tse Phahameng ka ho Fetisisa | Litsenyehelo tsa ho reka li tlase ho 20% -30% ho feta tsa li-crushers tlas'a maemo a tšoanang a bokhoni. |

| Boholo bo Fetohang | Saese ea ho bula e ka beoa habonolo lipakeng tsa 10-150mm ho sebelisa lisebelisoa tsa ho lokisa. |

Likarolo tsena li sebetsa ka kutloano ho fanatshebetso e phahameng, ho feto-fetoha ha maemo, le ho boloka litšenyehelo, ho etsa li-crushers tsa mohlahare e le khetho e ratoang bakeng sa lisebelisoa tsa indasteri.

Karolo ea ho Hatella Lintho

Li-crushers tsa mohlahare li ipabola tabeng ea ho senya thepa ka ho sebelisa mokhoa oa extrusion. Mohlahare o suthang o hatella lisebelisoa khahlanong le mohlahare o tsitsitseng, o sebelisa matla a hatellang ho li pshatla likotoana tse nyane. Ts'ebetso ena e sebetsa haholo bakeng sa ho fokotsa litšepe tse thata, majoe le litšila tsa kaho.

Moqapi oa kamore e sithabetsang o nang le sebopeho sa V o tiisa hore lisebelisoa li kena ka bophara holimo 'me li tsoa li le moqotetsane ka tlase, li thusa ho fokotsa boholo bo sebetsang hantle. Ho buloa ho ka feto-fetohang ho lumella basebelisi ho laola boholo ba tlhahiso, ho tloha ho likhechana tse mahoashe ho isa ho granularity e ntle.

Lipalopalo tsa ts'ebetso li totobatsa bohlokoa ba li-crushers tsa mohlahare ho silakanya lintho tse bonahalang:

- Sephetho:Li lekanngoa ka lithane ka hora (TPH), li-crushers tsa mohlahare li ka sebetsana le lithane tse makholo tsa thepa ho latela boholo ba tsona le maemo a tsona.

- Katleho:Lintlha tse kang lebelo la ho potoloha, geometry ea crusher, le litekanyetso tsa matla li ama ka kotloloho tlhahiso ea TPH.

- Litšobotsi tsa lintho tse bonahalang:Ho thatafala le mongobo li susumetsa katleho ea ho senya, ka lisebelisoa tse thata tse hlokang boiteko bo eketsehileng.

Li-crushers tsa mehlahare le tsona li kenya letsoho ho ts'ebetsong ka mokhoa o tsitsitseng ka ho nolofalletsa ho sebelisoa hape ha thepa ea kaho. Bokhoni ba bona ba ho sebetsana le lisebelisoa tse fapaneng tsa phepelo, ho kenyeletsoa lirafshoa tse thata le maloanlahla a ho heletsoa, ho totobatsa ho feto-fetoha ha bona le bohlokoa ba liindasteri tsa sejoale-joale.

Jaw Crusher Plate Bohareng le Molao-motheo oa ho sebetsa

Mokhoa oa ho pshatla

Mochine o silakanyang oa sefate sa mohlahare o itšetlehile ka ho sebelisana pakeng tsa lipoleiti tsa mohlahare tse tsitsitseng le tse tsamaeang. Letlapa la mohlahare le tsamaeang le tsamaea ka mokhoa o fananang, le tsamaisoang ke eccentric shaft. Motsamao ona o hatella lisebelisoa khahlanong le poleiti e tsitsitseng ea mohlahare, e sebelisa matla a khatello ho li pshatla likotoana tse nyane. The “Mehlahare Crusher Plate Bohareng” e bapala karolo ea bohlokoa ts'ebetsong ena, kaha e tiisa ho ajoa ha matla ho pholletsa le kamore e sithabetsang.

Sebopeho se bōpehileng joaloka V sa kamore ea ho senya se matlafatsa bokhoni ka ho tataisa lisebelisoa ho ea tlase e moqotetsane, moo ho senya ho qetela ho etsahalang. Moralo ona o fokotsa tahlehelo ea matla mme o netefatsa boholo ba thepa bo sa fetoheng. Basebelisi ba ka fetola phallo ea phallo ho laola boholo ba tlhahiso, ba etsa hore crusher ea mohlahare e ikamahanye le lits'ebetso tse fapaneng.

Keletso:Ho hlahloba khafetsa lipoleiti tsa mohlahare ho ka thibela ho apara ho sa tšoaneng, ho ka fokotsang ts'ebetso ea ho senya ka nako.

Ho fepa le ho lahla lintho tse bonahalang

Phepelo e nepahetseng ea lintho tse bonahalang le ho qhala li ama haholo ts'ebetso ea sebolaea sa mohlahare. Lisebelisoa tsa ho fepa ka mokhoa o laoloang li tiisa ts'ebetso e bonolo le ho thibela ho koala. "Jaw Crusher Plate Middle" e thusa ho phalla hantle ha thepa ka ho boloka kamore ea ho senya e leka-lekaneng.

Tafole e latelang e totobatsa mekhoa e metle ea ho fepa le ho ntša metsi le litlamorao tsa eona ho sebetsa hantle:

| Itloaetse | Tšusumetso ho Katleho |

|---|---|

| Ho fepa ka moleng | E fokotsa menyetla ea hore thepa e koale Jaw Crusher, e matlafatsa phallo le ho fokotsa nako. |

| Khama Ho fepa | E boloka kamore e sithabetsang e bonyane 80% e tletse, e ntlafatsa sebopeho sa thepa le katleho ka kakaretso. |

| Ho Tlosoa ha Lintho Tse Feteletseng | E thibela ho koaleha le ho thiba ha ho buloa ha crusher, ho netefatsa litekanyetso tse tsitsitseng tsa tlhahiso. |

| Lichelete tsa Scalping | E fokotsa ho koala ka kamoreng, e lelefatsa bophelo ba likarolo, 'me e boloka sebopeho se tsitsitseng sa sehlahisoa. |

Phallo e sebetsang e bohlokoa ka ho lekana. Ho buloa ho ka feto-fetohang ho lumella basebelisi ho laola boholo ba thepa e sithabetseng. Ho feto-fetoha ha maemo ho etsa bonnete ba hore sesebelisoa sa mohlahare se finyella litlhoko tse khethehileng tsa merero e fapaneng, ho tloha ho lihlopha tse mahoashe ho ea ho lisebelisoa tse ntle.

Bohlokoa ba Toggle Plate

Toggle plate e sebetsa e le karolo ea bohlokoa ts'ebetsong ea mochini o senyang mohlahare. E sebetsa e le mokhoa oa ts'ireletso, ho thibela tšenyo ea mochine o senyang haeba ho na le lintho tse ke keng tsa senyeha tse kenang ka kamoreng. The toggle plate e boetse e fetisetsa matla ho tloha ho eccentric shaft ho ea mohlahareng o sisinyehang, e leng se nolofalletsang ho senya.

Lintlafatso tsa morao-rao li ntlafalitse ts'ebetso ea toggle plate. Lipoleiti tse feto-fetohang tse nang le lisebelisoa tsa hydraulic li lumella basebelisi ho etsa liphetoho tse potlakileng, ho ntlafatsa maemo a ts'ebetso. Tafole e ka tlase e bonts'a bohlokoa ba ho fetola lipoleiti ts'ebetsong ea crusher ea mohlahare:

| Mofuta oa Bopaki | Tlhaloso |

|---|---|

| Ntlafatso ea Bokhoni | Ho iketsetsa lipoleiti tsa toggle ho ka ntlafatsa haholo ts'ebetso ea ts'ebetso ho ipapisitse le litšobotsi tsa thepa. |

| Tšireletseho Compliance | Li-toggle plate tsa boleng bo holimo tse tsoang ho bahlahisi ba hlomphehang li netefatsa ho khomarela litekanyetso tsa tšireletso, ho fokotsa likotsi tse amanang le mechine. |

| Tsoelo-pele ea Theknoloji | Litlhahiso tse kang lipoleiti tse feto-fetohang tse nang le lisebelisoa tsa hydraulic li lumella litokiso tse potlakileng ho fihlela litlhoko tse fetohang tsa ts'ebetso. |

The “Mehlahare Crusher Plate Bohareng” e sebetsa mmoho le toggle plate ho etsa bonnete ba ho silakanya ha bonolo le ho sebetsa hantle.Ka kopanelo, dikarolo tsena di kenya letsoho ho tshwarelleng le ho tshepeheng ha sesithari sa mohlahare, e leng se etsang hore e be kgetho e kgethehileng diindastering tse fapaneng.

Mefuta ea Mehatla Crushers

Li-Crushers tsa Mohlahare o le Mong

Li-crushers tsa mohlahare o le mong li na le moralo o otlolohileng o li etsange bobebe ebile e bonolo ho hlokomela. Li-crusher tsena li sebelisa ntlha e le 'ngoe ea pivot, e lumellang mohlahare o sisinyehang ho sisinyeha ka mokhoa o kang oa arc. Moralo ona o fokotsa palo ea likarolo tse tsamaeang, o matlafatsa ho ts'epahala le ho nolofatsa mesebetsi ea tlhokomelo.

- Melemo:

- Bokhoni bo phahameng ba ho senya le bokhoni.

- Boima bo tlase ha bo bapisoa le mehlala e meng.

- E loketseng bakeng sa likopo tsa merafo le kaho.

Ho nolofatsa ha li-crusher tsa mohlahare tse le 'ngoe ho li etsa hore li tuma libakeng tse nang le mesebetsi e mengata ea merafo. Bokhoni ba bona ba ho sebetsana le thepa e thata ka katleho bo netefatsa ts'ebetso e tsitsitseng maemong a hlokang.

Keletso: Ho tlotsa nako le nako ha ntlha ea pivot ho ka lelefatsa nako ea bophelo ea li-crushers tsa mohlahare o le mong le ho boloka ts'ebetso ea tsona.

Habeli-Toggle Jaw Crushers

Habeli-toggle mohlahare oa li-crushers lie etselitsoeng ho tšoarella le lits'ebetso tse boima. Li sebelisa li-toggle plates tse peli, tse etsang hore ho be le motsamao o rarahaneng haholoanyane bakeng sa mohlahare o sisinyehang. Moralo ona o ntlafatsa matla a ho pshatla, ho etsa hore li-crusher tsena li tšoanelehe bakeng sa ho sebetsana le lisebelisoa tse thata le tse hlabang.

| Sehlooho sa Thuto | Tsepamisa maikutlo | Liphuputso tsa Bohlokoa |

|---|---|---|

| Tlhahlobo e Matla ea Habeli Toggle Jaw Crusher U Sebelisa Pro | Moralo le bokhabane ba li-crusher tsa mohlahare tse habeli | E totobatsa ho fokotsa boima ba 'mele le ho boloka matla ho moralo oa swing plate, ka ho boloka boima ba 10-25%. |

| Moralo le Finite Element Analysis ea Swing Jaw Plate ea Jaw Crusher e nang le Stiffener | Papiso ea toggle e le 'ngoe le li-crusher tsa mohlahare tse kopaneng | E totobatsa papiso ea deformation le khatello ea maikutlo, e bonts'a melemo ea lisebelisoa tse kopaneng ho feta tšepe ea khale ea manganese. |

Li-crusher tsa mohlahare tse habeli li boima ebile li rarahane ho feta mefuta e le 'ngoe ea toggle, empa moralo oa tsona o tiileng o netefatsa ts'ebetso e tšepahalang liindastering tse hlokang matla a phahameng a ho silakanya.

Overhead Eccentric Jaw Crushers

Li-crusher tsa mohlahare tse ka holimo li sebelisa lesela la eccentric ho etsa motsamao o chitja bakeng sa mohlahare o suthang. Moralo ona o ntlafatsa ts'ebetso ea ho fepa le ho ntlafatsa ts'ebetso ea ts'ebetso ea ho senya.

- Melemo ea Moralo:

- Boima bo bobebe bakeng sa tshebediso e nkehang.

- Theko e tlase ha e bapisoa le mefuta e meng.

- Ho silakanya hantle ka baka la motsamao wa elliptical wiping.

| Melemo ea Moralo | Lisebelisoa |

|---|---|

| Boima bo bobebe | Tšebeliso e nkehang |

| Theko e tlase | Mokhoa o sebetsang oa ho senya |

| Ketso e ntle ea ho fepa | E loketse mefuta e fapaneng ea rock |

Overhead eccentric jaw crushers li loketse lits'ebetso tse hlokang ho tsamaea le ho feto-fetoha ha maemo. Leha ho le joalo, ts'ebetso e ntseng e eketseha e ka potlakisa ho roala lipoleiti tsa mohlahare, tse hlokang ho hlahlojoa khafetsa le ho nkeloa sebaka.

Hlokomela: Meralo e holimo-limo ha e tloaelehe haholo empa e fana ka melemo e ikhethang bakeng sa litlhoko tse ikhethang tsa indasteri.

Likarolo tsa Mohlahare oa Mohlahare

Mehlahare e Tsitsitseng le e Tsamaeang

E tsitsitseng le e tsamaeanglipoleiti tsa mohlahareke likarolo tsa bohlokoa tsa crusher ea mohlahare. Letlapa le tsitsitseng la mohlahare le lula le eme, ha karolo ea mohlahare e sisinyeha ho pshatla lisebelisoa. Hammoho, ba theha kamore e sithabetsang, moo thepa e fokotsoang ka boholo. "Jaw Crusher Plate Middle" e tiisa hore esita le ho ajoa ka matla ho pholletsa le kamore, ho ntlafatsa ts'ebetso le ho fokotsa ho apara.

Lithuto tsa papiso li totobatsa bohlokoa ba moralo oa poleiti ea mohlahare. Mohlala:

| Sehlooho sa Thuto | Liphuputso tsa Bohlokoa |

|---|---|

| Tlhahlobo ka Thuto ea Mehlahare ea Jaw Crusher | Ho boloka boima ba 'mele ho 10-25% ka ntlafatso ea moralo. |

| Tšebeliso ea The New Shape Crushing Plate | Lekola ho nepahala ha li-profiles tse ncha bakeng sa ts'ebetso e ntle. |

Ke habohlokoa ho hlahloba le ho hlokomela lipoleiti tsa mohlahare kamehla. Ho apara ka tsela e sa tšoaneng ho ka fokotsa katleho ea ho senya le ho eketsa litšenyehelo tsa ts'ebetso.

Keletso:Ho fetola lipoleiti tse tsofetseng hang-hang ho netefatsa ts'ebetso e tsitsitseng le ho thibela tšenyo ea likarolo tse ling.

Toggle Plate le Pitman

The toggle plate le pitman li bapala karolo ea bohlokoa ts'ebetsong ea mochini oa mohlahare. Toggle plate e sebetsa e le mokhoa oa polokeho, o etselitsoeng ho robeha haeba thepa e sa senyeheng e kena ka phaposing. Sena se thibela tšenyo e matla ho pitman le likarolo tse ling. Ho feta moo, toggle plate e fetisetsa matla ho tloha ho eccentric shaft ho ea mohlahareng o tsamaeang, e leng se nolofalletsang ho senya.

Thepitmane tshehetsa mohlahare o tsamayang mme e hlalosa setorouku sa crusher. Moralo oa eona o matla o tiisa ho tšoarella le katleho ea ts'ebetso. Mesebetsi ea bohlokoa e kenyelletsa:

- Tšireletseho:Toggle plate e sireletsa pitman le foreimi hore li se ke tsa senyeha.

- Tšehetso:E fana ka setulo bakeng sa pitman mme e thusa ho hlalosa motsamao oa crusher.

- Katleho:Hammoho, toggle plate le pitman li netefatsa ts'ebetso e bonolo le ts'ebetso e tsitsitseng ea ho senya.

| Karolo | Mosebetsi | Bohlokoa |

|---|---|---|

| Toggle Plate | E sebetsa e le sehokelo sa sehlabelo ho sireletsa pitman le foreimi hore e se ke ea senyeha. | Bohlokoa bakeng sa polokeho; e thibela ho senyeha ho matla ho likarolo tse ling. |

| Pitman | E fana ka tšehetso le ho hlalosa stroke ea crusher. | E bohlokoa bakeng sa ts'ebetso ea ts'ebetso ea "crusher" ea mohlahare. |

Flywheel le Eccentric Shaft

The flywheel le eccentric shaft li bohlokoa bakeng sa ho sebetsa hantle ha sefate sa mohlahare. Flywheel e boloka matla le ho leka-lekanya shaft ea eccentric, e netefatsa hore ho tsamaea ha bonolo le ho tsoelang pele. Sena se fokotsa tahlehelo ea likhohlano le ho ntlafatsa ts'ebetso ea crusher ka kakaretso.

The eccentric shaft e etsa motsamao o hlokahalang bakeng sa mohlahare o tsamaeang. E fetola matla a motlakase hore e be motsamao o iphetang o hlokahalang bakeng sa ho silakanya. Ka kopanelo, likarolo tsena li thusa ho boloka matla le ho sebetsa hantle.

| Karolo | Seabo ho Sebetsa |

|---|---|

| Flywheel | E loantšana le eccentric shaft, e nolofalletsang ho sisinyeha ha 'nete le ho fokotsa tahlehelo ea likhohlano. |

| Eccentric Shaft | E etsa motsamao o hlokahalang skrineng, e thusa ho boloka matla le ho sebetsa hantle ka kakaretso. |

Hlokomela:Ho tlotsa khafetsa ha shaft ea eccentric le tlhahlobo ea flywheel ho ka thibela ho hloleha ha mochini le ho netefatsa ts'ebetso e nepahetseng.

Lisebelisoa le Melemo

Liindasteri tse Sebelisang Li-Jaw Crushers

Li-crushers tsa mehlahare li fumana lits'ebetso liindastering tse 'maloa ka lebaka la bokhoni ba tsona ba ho sebetsana le lisebelisoa tse fapaneng hantle. Li-crusher tsena li sebelisoa haholo ho:

- Morafo: Ba pshatla majoe a maholo le li-ores ka boholo bo nyane bakeng sa ts'ebetso e tsoelang pele.

- Kaho: Li-crushers tsa mohlahare li sebelisa lisebelisoa tse kang konkreite le asphalt, li fokotsa litšila le ho nolofalletsa ho sebelisoa hape mererong e mecha.

- Recycling: Ba fetola lisebelisoa tsa litšila hore e be lihlahisoa tse ka sebelisoang, ho kenya letsoho mekhoeng e tsitsitseng.

Litlaleho tsa mebaraka li totobatsa tlhoko ea bona e ntseng e hola lekaleng la kaho, e susumetsoang ke kholo ea litoropo le nts'etsopele ea meaho. Likhamphani tse kang Epiroc le McCloskey li lokisa li-crusher tsa mohlahare bakeng sa litlhoko tse ikhethileng, joalo ka kaho ea litoropong kapa meepo e meholo. Ntle le moo, melaoana e thata ea tikoloho mebarakeng e tsoetseng pele e khothaletsa ho amoheloa ha li-crushers tse sebetsang hantle ka tikolohong, ho theha menyetla bakeng sa bahlahisi ba hloahloa.

| Indasteri | Kopo |

|---|---|

| Morafo | Ho pshatla ores le majoe bakeng sa ts'ebetso e tsoelang pele. |

| Kaho | Ho sebelisoa hape konkreite le asphalt bakeng sa ho sebelisoa hape mererong e mecha. |

| Recycling | Ho fetolela litšila hore e be lihlahisoa tse ka sebelisoang. |

Melemo Ho Feta Li-Crushers Tse Ling

Li-crushers tsa mohlahare li fana ka melemo e mengata ha li bapisoa le litharollo tse ling tse senyang. Ba sebetsana le mefuta e fapaneng ea lisebelisoa, ho kenyelletsa le granite e thata le sebaka sa sekontiri se tsosolositsoeng, kaho apara hanyaneho feta li-crushers tsa mofuta oa mantlha. Boholo ba bona bo kopaneng bo ba etsa hore ba tšoanelehe bakeng sa libaka tse thata, joalo ka merafo e ka tlas'a lefatše le lisebelisoa tsa mehala.

Melemo ea bohlokoa e kenyelletsa:

- Lisebelisoa tse Nyenyane tse Ntle: Li-crushers tsa mohlahare li hlahisa lerōle le lenyenyane le likaroloana tse ntle, tse netefatsang ts'ebetso e hloekileng.

- Tšebeliso ea Litšenyehelo: Theko e tlaase ea thepa le litšenyehelo tsa tlhokomelo li etsa hore bakhetho e hlokang chelete e ngata.

- Ho feto-fetoha ha maemo: Li ikamahanya le lisebelisoa le lits'ebetso tse fapaneng, ho tloha merafong ho isa ho recycle.

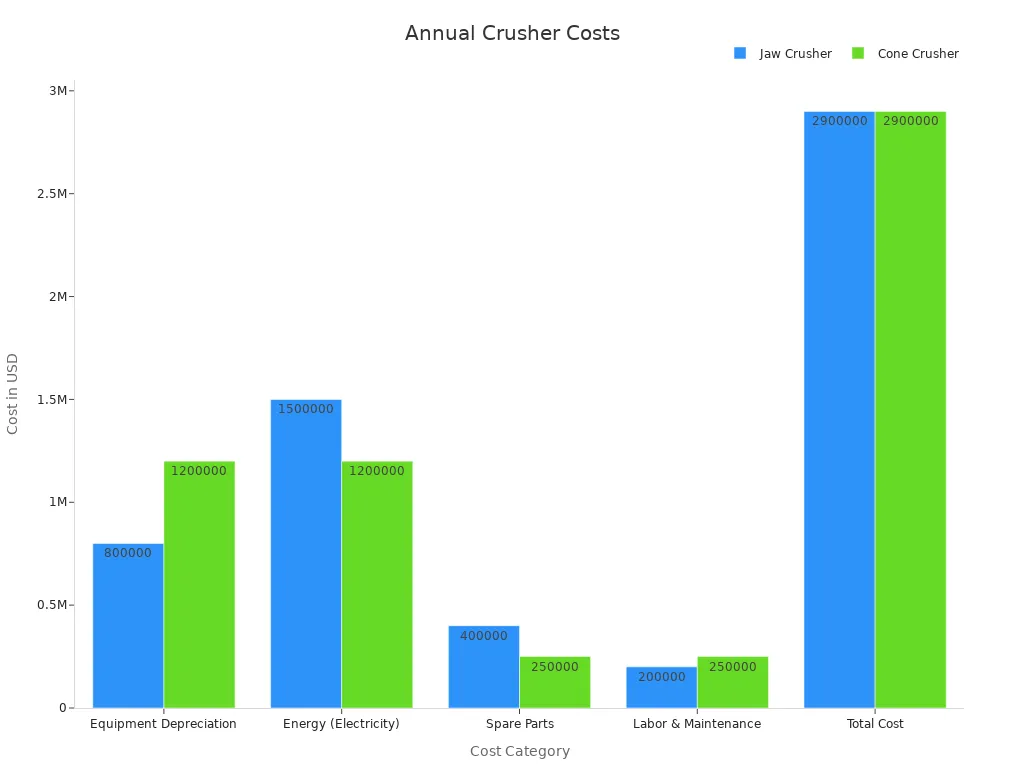

| Sehlopha | Jaw Crusher (Selemo le selemo) | Cone Crusher (Selemo le selemo) |

|---|---|---|

| Thepa ea Thepa | $800,000 | $1,200,000 |

| Matla (Motlakase) | $1,500,000 | $1,200,000 |

| Likarolo tsa tlatsetso | $400,000 | $250,000 |

| Mosebetsi le Tlhokomelo | $200,000 | $250,000 |

| Kakaretso ea Litšenyehelo | $2,900,000 | $2,900,000 |

Ho feto-fetoha ha maemo le ho sebetsa ka katleho

Li-crusher tsa mehlahare li ipabola ka ho feto-fetoha ha maemo le ho sebetsa hantle, li etsa hore e be tsa bohlokoa haholo liindastering tse fapaneng. Litlhophiso tsa bona tse feto-fetohang li lumella basebelisi ho fetola boholo ba likaroloana tsa ho qetela ka ho fetola lekhalo pakeng tsa lipoleiti tse silakanyang. Ho ikamahanya le maemo ho etsa bonnete ba ho tšoaneleha bakeng sa ho sithabela ha bobeli kapa ba thuto e phahameng.

Litlhahlobo tsa katleho li netefatsa bokhoni ba bona ba ho sebetsa ka mokhoa o tsoelang pele ka nako e fokolang, ho ntlafatsa tlhahiso. Li-crushers tsa mohlahare li boetse li sebetsana le mefuta e mengata ea lisebelisoa, ho kenyeletsoa li-ores, litšila tsa kaho, le li-aggregates, tse bontšang ho sebetsa ha tsona ka bophara.

| Metric | Tlhaloso |

|---|---|

| Katleho | Bokhoni bo phahameng ba ho senya thepa, e loketseng bakeng sa ho silakanya ha bobeli kapa ba thuto e phahameng. |

| Litlhophiso tse Fetohang | Bokhoni ba ho fetola boholo ba karolo ea ho qetela ka ho fetola lekhalo pakeng tsa lipoleiti tse silakanyang. |

| Tlhahiso | E khona ho sebetsa ka mokhoa o tsoelang pele ka nako e fokolang, ho ntlafatsa tlhahiso ka kakaretso. |

| Ho feto-fetoha ha maemo | E ikamahanya le lisebelisoa tse fapaneng, ho kenyeletsoa ores, litšila tsa kaho, le li-aggregates. |

| Lisebelisoa tsa indasteri | E sebelisoa merafong, kahong, le ho e sebelisa hape, ho bontša hore e sebetsa ka bophara. |

Li-crushers tsa mohlahare li kopanya ts'ebetso, ho ikamahanya le maemo, le ho boloka litšenyehelo, ho li etsa khetho e ratoang bakeng sa lisebelisoa tsa indasteri.

Mekhoa ea Bokamoso ho Li-Jaw Crushers (2025)

Automation le Smart Technology

Li-crusher tsa mehlahare ka 2025 li tla amohela li-automation tse tsoetseng pele le theknoloji e bohlale ho ntlafatsa ts'ebetso le ho fokotsa litšenyehelo tsa ts'ebetso. Artificial Intelligence (AI) e tla thusa ho lekola ts'ebetso ea crusher ka nako ea nnete, ho tseba mathata a ka bang teng pele a eketseha. Sistimi ea ho lokisa esale pele e tla fokotsa nako ea ho theoha ka ho hlophisa litokiso tse ipapisitseng le ts'ebeliso ea mochini le lipaterone tsa moaparo. Li-algorithms tsa ho ithuta ka mochini li tla ntlafatsa ts'ebetso, li netefatse ho nepahala le ho fokotsa liphoso tsa batho.

Baetsi ba tla kopanya mafahla a dijithale le li-analytics tse thehiloeng marung ho ntlafatsa phallo ea mosebetsi. Lisebelisoa tsena li tla lumella basebelisi ho etsisa ts'ebetso ea crusher le ho etsa liqeto tse tsamaisoang ke data. Li-platform tse thehiloeng ho lisebelisoa tsa mohala li tla fa basebelisi phihlello ea hole ea tlhahlobo ea mochini, ho ntlafatsa litšebeletso tsa bareki le taolo ea bophelo. Merero ea meralo ea modular e tla nolofatsa ho kopanya le ho e etsa, ho sebetsana le litlhoko tse fapaneng tsa indasteri.

Moshoelella le Matla a Matla

Matšoenyeho a tikoloho a tla etsa hore ho amoheloe litloaelo tse tšoarellang molemong oa moralo oa ho senya mehlahare. Mefuta ea motlakase le ea lebasetere e tla nkela li-crushers tsa setso tse tsamaisoang ka diesel, ho fokotsa khabone le ho kopana le melao e thata ea tikoloho. Likarolo tse baballang matla, joalo ka lienjineri tse tsoetseng pele le likamore tse pshatlehang tse ntlafalitsoeng, li tla theola tšebeliso ea matla ntle le ho senya ts'ebetso.

Bokhoni ba ho sebelisa hape bo tla ntlafala. Li-crushers tsa mohlahare li tla sebetsana le maloanlahla a kaho ka mokhoa o atlehileng haholoanyane, ho kenya letsoho moruong o chitja. "Jaw Crusher Plate Middle" e tla bapala karolo ea bohlokoa ho ntlafatseng phallo ea thepa, ho netefatsa ts'ebetso e nepahetseng ea ho e sebelisa hape. Likhatelo-pele tsena li tla ikamahanya le lipheo tsa ts'ebetso ea lefats'e, ho etsa hore li-crushers e be khetho e bonolo bakeng sa liindasteri.

Matla le Tlhokomelo e Matlafalitsoeng

Li-crusher tsa mehlahare tsa nako e tlang li tla ba le matla a ho tšoarella ho mamella lits'ebetso tse boima. Lisebelisoa tse matla le meralo e ncha li tla lelefatsa nako ea bophelo ea likarolo tsa bohlokoa, joalo ka lipoleiti tsa mohlahare le li-toggle plate. Ntlafatso ea khanyetso ea ho apara e tla fokotsa khafetsa ea ho nkela sebaka, ho fokotsa litšenyehelo tsa tlhokomelo.

Mekhoa ea tlhokomelo e tla ba bonolo haholoanyane ho basebelisi. Sistimi ea Hydraulic e tla nolofatsa litokiso, athe litemoso tse ikemetseng li tla tsebisa basebelisi ka tokiso e hlokahalang. Litlhahiso tsena li tla netefatsa ts'ebetso e tsitsitseng le ho fokotsa nako, ho etsa hore li-crushers tsa mohlahare li tšepahale ho feta leha e le neng pele.

Li-crusher tsa mehlahare e ntse e le lisebelisoa tsa bohlokoa liindastering tse kang tsa merafo, kaho le ho li sebelisa hape. Bokhoni ba bona ba ho sebetsana le lisebelisoa tse fapaneng ka katleho bo tsoa holikarolo tsa bohlokoa joalo ka lipoleiti tsa mohlahare, toggle plates, le flywheels. Moetso o mong le o mong oa crusher o na le litlhoko tse ikhethang, ho kenyelletsa le meralo e ikhethileng ea lipoleiti tsa mohlahare le mekhoa ea ho homa, e etselitsoeng ts'ebeliso ea eona e reriloeng. Lisebelisoa tse phahameng tsa ho hanyetsa li etsa bonnete ba hore li tšoarella, haholo-holo ha li sebetsana le lisebelisoa tsa abrasive.

Li-crusher tsa mehleng ea kajeno li etelletsa pelematla a matla, botsitso, le ho latela maemo a tikoloho. Litlhahiso tse kang li-automation le lisebelisoa tse tsoetseng pele li ntlafatsa ts'ebetso ha li ntse li fokotsa litlhoko tsa tlhokomelo. Tsoelo-pele ena e beha li-crushers tsa mohlahare e le tsa bohlokoa ho finyella litlhoko tsa indasteri le ho finyella mekhoa e tsitsitseng.

Hlokomela: Ho khetha crusher e nepahetseng ho kenyelletsa ho leka-lekanya bokhoni, tekanyetso, le litlhoko tsa tekheniki ho netefatsa ts'ebetso e nepahetseng.

LBH

Ke lisebelisoa life tse ka etsang ts'ebetso ea crusher ea mohlahare?

Li-crushers tsa mehlahare li sebetsana le mefuta e mengata ea lisebelisoa, ho kenyeletsoa majoe a thata, li-ores, konkreite le litšila tsa kaho. Li loketse bakeng sa ho pshatla thepa ea abrasive joalo ka granite le basalt, hammoho le lisebelisoa tse bonolo joalo ka mokoetla. Ho feto-fetoha ha tsona ho etsa hore li tšoanelehe bakeng sa indasteri ea merafo, ea kaho le ea ho e sebelisa hape.

Lipoleiti tsa mohlahare li lokela ho nkeloa sebaka hangata hakae?

Khafetsa eajaw plate replacemente ipapisitse le boima ba lintho tse bonahalang le tšebeliso ea crusher. Basebelisi ba lokela ho hlahloba lipoleiti khafetsa hore na li senyehile. Ho nkeloa sebaka hoa hlokahala ha lipoleiti li bontša ho apara ho hoholo kapa libaka tse sa tšoaneng, kaha sena se tiisa ts'ebetso e tsitsitseng le ho thibela tšenyo ea likarolo tse ling.

Karolo ea toggle plate ka har'a tšila ea mohlahare ke efe?

Toggle plate e sebetsa joalo ka mokhoa oa polokeho le mochini o fetisang matla. E sireletsa sekontiri hore se senyehe ka ho pshatla haeba thepa e sa senyeheng e kena ka kamoreng. Ho phaella moo, e fetisetsa matla ho tloha ho eccentric shaft ho ea mohlahareng o sisinyehang, e leng ho nolofalletsang ketso ea ho senya.

Boiketsetso bo ntlafatsa ts'ebetso ea "crusher" joang?

Automation e ntlafatsa ts'ebetso ka ho nolofalletsa ho beha leihlo ka nako ea 'nete le ho hlokomela esale pele. Litsamaiso tse bohlale li supa mathata a ka bang teng esale pele, li fokotsa nako ea ho theoha. Liphetoho tse ikemetseng li ntlafatsa ts'ebetso, li netefatsa tlhahiso e tsitsitseng le ts'ebetso e nepahetseng. Likhatelo-pele tsena li etsa hore li-crushers li tšepahale le ho boloka chelete e ngata.

Na li-crushers tsa mohlahare li ka kenya letsoho ho tšoarella?

Li-crusher tsa mehlahare li tšehetsa botsitso ka ho sebelisa lisebelisoa tsa kaho tse kang konkreite le asphalt. Li fokotsa litšila 'me li nolofalletsa tšebeliso ea thepa hape mererong e mecha. Mehlala e baballang matla le li-crusher tse tsamaeang ka motlakase li fokotsa ts'usumetso ea tikoloho, li ikamahanya le lipheo tsa ts'ebetso ea lefats'e.

Nako ea poso: Jun-05-2025