Tšireletseho e tla pele ha batho ba nka sebakalikarolo tsa li-crusher. Basebetsi ba sebelisa lisebelisoa tse nepahetseng le lisebelisoa tsa ho itšireletsa. Ba latela litataiso tsa moetsi bakeng saLikarolo tsa Cone Crusher, Mohlahare oa Mohlahare oa Mohlahare oa Manganese Steel, leLikarolo tsa Bronze. Lihlopha li hlahlobapitman ea mohlaharepele o qala mosebetsi. Liphoso li ka baka likotsi.

Lintlha tsa bohlokoa

- Kamehla u koale 'me u koale mochini o silafatsang pele o kenya likarolo tse tsofetseng ho thibela likotsi le ho netefatsa polokeho ea basebetsi.

- Sebelisa lisebelisoa tse nepahetseng, lisebelisoa tsa ts'ireletso ea botho, 'me u latele mehato ea mohato ka mohato ho tlosa le ho kenya mekhoa ea hosireletsa basebetsi le lisebelisoa.

- Boloka puisano e hlakileng le koetliso ea kamehla har'a litho tsa sehlopha ho ntlafatsa polokeho, ho fokotsa nako ea ho phomola, lelelefatsa bophelo ba likarolo tsa crusher.

Boitokisetso bakeng sa Sireletsehile Crusher Wear Replacement

Ho Koala Mochini le ho Ikhetha

Pele motho leha e le ofe a ama crusher, o lokela ho etsa bonnete ba hore mochine o tima ka ho feletseng. Lihlopha li koala lisebelisoa ebe li li arola mohloling ofe kapa ofe oa matla. Mohato ona o boloka bohle ba bolokehile hore ba se ke ba qala ka phoso. Basebetsi ba bokella lisebelisoa tsohle le likarolo tse ncha tseo ba li hlokang. Ba boetse ba hlahloba sebaka seo bakeng sa tšenyo leha e le efe e ka bakang mathata hamorao.

Keletso:Kamehla u roale thepa e nepahetseng ea ho itšireletsa (PPE) pele u qala. Sena se kenyelletsa likatiba tse thata, likhalase tsa tšireletso, liatlana, lieta tse entsoeng ka tšepe, le li-vest tse bonahalang haholo. Tšireletso ea kutlo e boetse e bohlokoa libakeng tse lerata.

Mekhoa ea ho koala / ea Tagout

Ts'ebetso ea Lockout/tagout (LOTO) e sireletsa basebetsi khahlanong le tokollo ea matla e neng e sa lebelloa. Lihlopha li sebelisa linotlolo le li-tag ho sireletsa li-switches le li-valve. Ba etsa bonnete ba hore ha ho motho ea ka bulelang crusher ka phoso. Mosebeletsi e mong le e mong o beha senotlolo sa hae le tag mohloling oa matla. Ka tsela ena, bohle ba tseba hore na ke mang ea sebetsang mochineng.

- Mehato ea LOTO hangata e kenyelletsa:

- Koala sekontiri.

- Arola mehloli eohle ea matla.

- Notlela 'me u tšoaee mohloli o mong le o mong.

- Teko ea ho netefatsa hore mochini ha e khone ho qala.

Ho Hloekisa le ho Hlophisa Sebaka sa Mosebetsi

Sebaka sa ho sebetsa se hloekileng le se hlophisitsoeng se thusa ho thibela likotsi. Basebetsi ba tlosa lithōle, lisebelisoa le thepa e setseng sebakeng seo. Ba beha mabone a nepahetseng 'me ba etsa bonnete ba hore litsela tsa maoto li hlakile. Lihlopha li sebelisa lisebelisoa tse nepahetseng tsa ho phahamisa, joalo ka li-hoists kapa li-slings, bakeng sa boimaLikarolo tsa li-crusher. Tlhophiso e ntle e thusa bohle ho sebetsa ka potlako le ka mokhoa o sireletsehileng.

Ho Khetholla Likarolo Tse Senyehileng Tsa Crusher

Mekhoa ea ho Hlahloba ka Pono

Lihlopha li sebelisa tlhahlobo ea pono e le mohato oa pele oa ho bona mathata kaLikarolo tsa li-crusher. Ba hloekisa likarolo ka borashe, li-compressor tsa moea kapa lijete tsa metsi. Sena se ba thusa ho bona mapetsong, li-chips kapa libaka tse sa tšoaneng. Basebetsi ba batla matheba a benyang, li-grooves kapa likotoana tse sieo. Ba lekanya botebo le boholo ba libaka tse tsofetseng ka li-caliper kapa li-gauge. Ho lekola ho lekana le ho tsamaisana ha karolo ka 'ngoe ho thusa ho rarolla mathata esale pele. Ho hloekisa kamehla le ho hlahloba ho etsa hore ho be bonolo ho fumana mathata pele a mpefala.

Keletso:Ho boloka tlaleho e qaqileng ea tlhokomelo ho thusa lihlopha ho latela tlhahlobo le tse ling. Rekoto ena e etsa hore ho be bonolo ho rera 'me e thusa ho bona mekhoa ea ho apara.

Ho Lemoha Matšoao a ho Khapeha le Tšenyo

Basebetsi ba batla matšoao a tloaelehileng a bontšang hore likarolo tsa Crusher li hloka tlhokomelo. Matshwao ana a kenyeletsa tshepe e tshesane, mengwapo e tebileng, le mathoko a robehileng. Ka linako tse ling, likarolo li bontša ho apara ho sa tšoaneng kapa lerata le sa tloaelehang nakong ea ts'ebetso. Lihlopha li hlahloba liboutu tse hlephileng kapa likotoana tse sa lumellaneng. Ba boetse ba shebella ho sisinyeha kapa liphetoho ts'ebetsong. Likarolo tse atileng haholo tse hlokang ho nkeloa sebaka li kenyelletsa lipoleiti tsa tšepe tsa manganese, lithapo tsa tšepe tsa chromium, le likarolo tsa tšepe ea alloy.

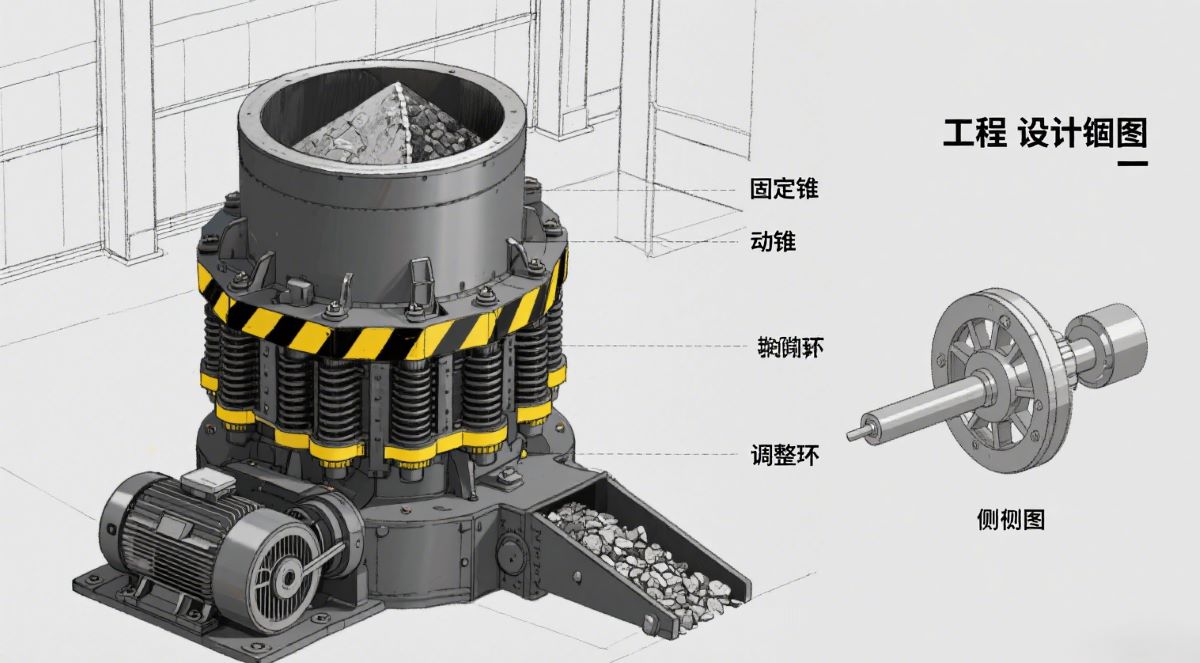

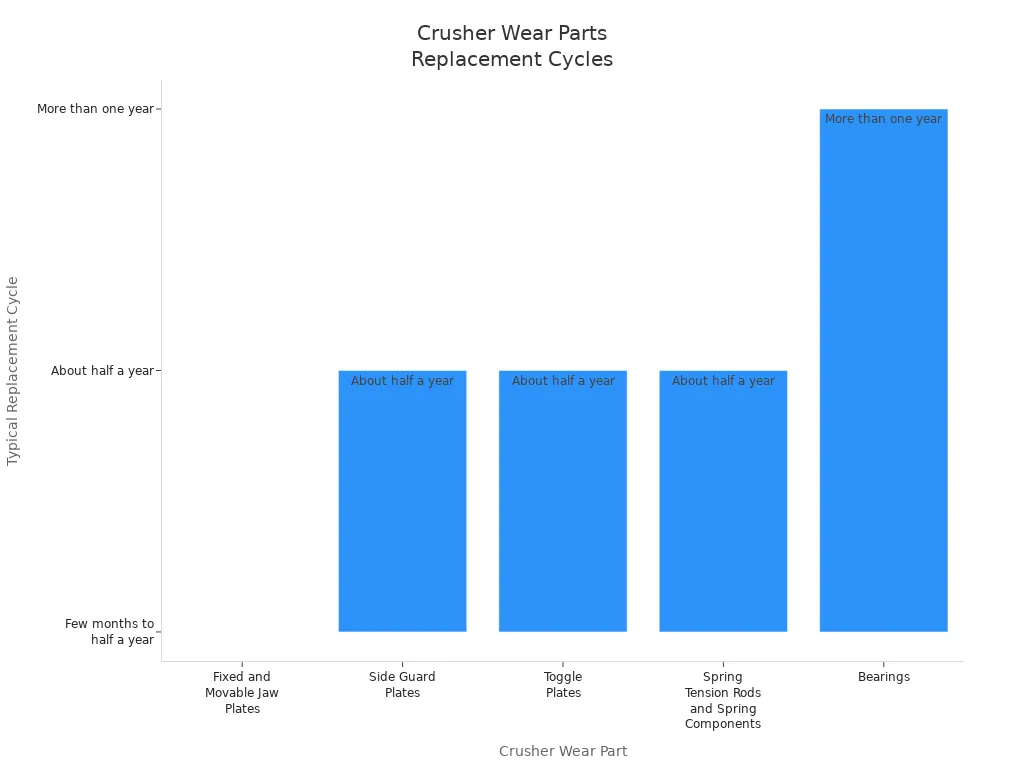

| Karolo ea ho roala li-crusher | Mosebetsi / Karolo | Apara Litšobotsi le Sesosa | Tloaelehileng Replacement Cycle |

|---|---|---|---|

| E Tsitsitseng ebile ea SuthehaMehlahare | Likarolo tse ka sehloohong tse sebetsang tse nang le tšusumetso e kholo nakong ea ho sila | Ho apara ka ho teba haholo-holo likarolong tse bohareng le tse tlaase ka lebaka la tšusumetso e pheta-phetoang le likhohlano | Likhoeli tse 'maloa ho isa ho halofo ea selemo ho itšetlehile ka tšebeliso le boima ba lintho tse bonahalang |

| Lipoleiti tsa Side Guard | Sireletsa 'mele oa crusher ho tsoa linthong tse bonahalang | Apara ho tloha tšusumetsong ea lintho tse bonahalang | Hoo e ka bang halofo ea selemo, e fapana ka matla a tšebeliso |

| Fetolela Lipoleiti | Hokela lipoleiti tsa mohlahare tse tsamaeang le tse tsitsitseng; sebetsa joalo ka likarolo tsa inshorense ho thibela tšenyo | Ho robeha ka tlas'a moroalo ho sireletsa crusher; ho thella hoa kgohlang e nyane | Hoo e ka bang halofo ea selemo |

| Melamu ea Khahlano ea Selemo le Likarolo tsa Selemo | Hokela setulo sa ho lokisa le poleiti ea tšehetso ea morao; boloka botsitso le monya thothomelo | Ho thothomela ha buffer le tšusumetso; ho roala kapa ho senyeha ho hloka phetoho e nakong | Hoo e ka bang halofo ea selemo |

| Bearings | Jara meroalo ea radial nakong ea ts'ebetso | Apara tlas'a mojaro o phahameng oa nako e telele; hloka ho hlahlojoa le ho nkeloa sebaka | Ka kakaretso ho feta selemo se le seng |

Ho Ikhethela Nako ea ho Fetola Nako

Lihlopha li sebetsa le bafani ba thepa ho utloisisa mekhoa ea ho apara le ho theha linako tsa tlhokomelo. Hangata li nka sebaka sa mantle le li-cone liners ka nako e le 'ngoe ho boloka likarolo tse tšoanang le ho fokotsa kotsi ea ho hlōleha. Ho beha leihlo litekanyetso tsa ho apara le ho lokisa litlhophiso ho thusa ho ntlafatsa bophelo ba karolo le ho fokotsa nako ea ho theoha. Ho hlahlojoa khafetsa, ho hloekisa, le tlhokomelo e thibelang likokoana-hloko-joaloka li-lubrication le licheke tsa ho tsamaisana-ho boloka li-crushers li sebetsa ka mokhoa o sireletsehileng. Licheke khafetsa li thusa lihlopha ho tšoara mathata kapele le ho qoba ho li lokisa tse bitsang chelete e ngata.

Ho tlosoa ho Sireletsehile le ho Kenyetsoa ha Likarolo tsa Crusher Wear

Ho Sebelisa Lisebelisoa le Lisebelisoa tse Nepahetseng

Ho khetha lisebelisoa tse nepahetseng ho etsa phapang e kholo polokehong le ts'ebetsong. Lihlopha li sebelisa li-wrenches, li-wrenches tsa torque, le lisebelisoa tsa ho hokahanya ho tlosa le ho kenya likarolo tsa liaparo tsa Crusher. Lisebelisoa tsa ho phahamisa joalo ka li-cranes kapa li-hoists li thusa ho tsamaisa lipoleiti tse boima tsa mohlahare ntle le ho beha kotsi. Liwebsaete tse ngata hona joale li sebelisa lisebelisoa tse khethehileng tsa ho phahamisa tse kang LockLift™ le Safe-T Lift™. Lisebelisoa tsena li latela litekanyetso tse thata tsa Australia 'me li thusa basebetsi ho qoba litšepe tse phahamisang litšepe, tse ka bang kotsi. LockLift ™ e sebelisa selikalikoe sa toche se nang le tokelo ea molao, e etsa hore ts'ebetso e potlake hape e bolokehe. Safe-T Lift™ e lumella basebetsi hore ba tlose li-liner ntle le ho kena ka phaposing e pshatlehang, e leng ho thibelang motho e mong le e mong kotsing.

Keletso:Kamehla hlahloba lisebelisoa le lisebelisoa tsa ho itšireletsa pele u qala. Likatiba tse thata, likhalase tsa tšireletso, liatlana, libutsi tsa menoana ea tšepe, le limaske tsa lerōle li sireletsa matlakala le lerōle le oelang.

Mokhoa oa ho Tlosa Mohato ka Mohato

Mokhoa o hlakileng oa ho tlosa o boloka bohle ba sireletsehile mme o thibela tšenyo ea thepa. Baetsi ba ka sehloohong ba khothaletsa mehato ena:

- Tlosa motlakase 'me u sebelise lisebelisoa tsa ho koala/tagout. Sena se etsa hore mochini o silafatsang o se ke oa qala ka tsietsi.

- Leka ho qala mochini ho etsa bonnete ba hore o tima le likarolo tsohle tse tsamaeang li emisitse.

- Tlosa likoahelo tsa tšireletso kapa liphanele ka lisebelisoa tse nepahetseng.

- Lokolla liboutu ka mokhoa oa crisscross. Sena se thibela khatello ea kelello likarolong.

- Sebelisa lisebelisoa tsa ho phahamisa ho tlosa ka hloko li-liner tsa khale kapa lipoleiti tsa mohlahare.

- Lekola likarolo tse tlositsoeng bakeng sa mapetsong kapa tšenyo. Ngola ntho leha e le efe e sa tloaelehang.

- Hloekisa libaka tse ntseng li hola ho tlosa mafome, mafura kapa litšila.

Ho latela mehato ena ho thusa lihlopha ho qoba liphoso le ho bolokaLikarolo tsa li-crushere maemong a matle bakeng sa ho instola tse latelang.

Ho kenya Likarolo tse Ncha tsa Wear ka Tsela e Sireletsehileng

Ho kenya ka nepo ho bohlokoa joalo ka ha ho tlosoa ho bolokehile. Lihlopha li theha likarolo tse ncha tsa Crusher li sebelisa lisebelisoa tsa ho ikamahanya. Ba tiisa liboutu ho torque e khothaletsoang ke moetsi. Sena se thibela ho se tsamaisane hantle, ho ka bakang ho apara ho sa tšoaneng kapa esita le ho hlōleha ha thepa. Ho sebelisa lisebelisoa tse nepahetseng le ho latela litaelo ho thusa ho qoba ho chesa haholo, ho thothomela le ho thibela. Lihlopha li boetse li hlahloba hore na ho na le lubrication e nepahetseng le ho etsa bonnete ba hore li-sensor le litsamaiso tsohle tsa taolo lia sebetsa. Ho tlōla mehato ena ho ka lebisa litšenyehelong tse phahameng tsa tlhokomelo le ho fokotsa nako e ngata.

Hlokomela:Likarolo tse sa kenngoeng hampe kapa tse kentsoeng hantle li felloa ke matla ka potlako 'me li ka senya sekontiri. Kamehla hlahloba ho baloa ha boliti habeli.

Khokahano ea Sehlopha le Puisano

Tšebelisano e ntle e boloka mosebetsi o bolokehile ebile o sebetsa hantle. Mananeo a ho ntlafatsa ho koala a bontša hore moralo, koetliso le puisano e hlakileng li thusa lihlopha ho qeta kapele le liphoso tse fokolang. Motho e mong le e mong o tseba karolo ea hae, 'me bohle ba latela mehato e tšoanang ea polokeho. Lihlopha li tlosa mesebetsi eo e seng ea bohlokoa 'me li tsepamise maikutlo ho tse bohlokoa haholo. Meepong e meng, khokahanyo e betere e fokolitse linako tsa ho koala hoo e ka bang halofo. Litlhahlobo tsa kamehla le linako tsa tlhokomelo li sebetsa feela ha bohle ba lula ba lumellana. Basebelisi, basebetsi ba lokisang, le litsebi ba tlameha ho sebetsa 'moho ho khutlisa likarolo tsa Crusher ka mokhoa o sireletsehileng le ka nako.

Ha motho e mong le e mong a buisana 'me a sebetsa e le sehlopha, kotsi ea likotsi ea theoha 'me mochini o senyang o sebetsa betere.

Litlhahlobo ka mor'a ho fetola likarolo tsa Crusher Wear

Teko le Ts'ebetso ea Pele

Kamora ho kenya likarolo tse ncha tsa Crusher, sehlopha se lokela ho qala ka tlhahlobo e hlokolosi. Ba boloka "crusher" e emisitsoe 'me e koaletsoe ka ntle ha ba ntse ba hlahloba boima ba karolo ka' ngoe le ho etsa bonnete ba hore thepa ea ho phahamisa e ka sebetsana le eona. Basebetsi ba sebelisa lisebelisoa tse khethehileng ho sireletsa likarolo le ho hlahloba masoba a phahamisanglipoleiti tsa marameng. Ha mochine o silafatsang o qala, ba mamela melumo e sa tloaelehang 'me ba shebeletse ho reketla leha e le hofe. Ba hlahloba boholo ba sehlahisoa le boleng. Haeba ho bonahala eka ho na le ho hong, ba emisa mochini ebe ba sheba mathata. Lihlopha li boetse li hlahloba tsamaiso ea lubrication ho etsa bonnete ba hore maemo a oli le khatello li nepahetse. Tlhahlobo ena ea pele e thusa ho tšoara mathata pele e fetoha mathata a maholo.

Tlhahlobo ea ho Qetela le Litokiso

Tlhahlobo ea ho qetela e etsa bonnete ba hore ntho e 'ngoe le e' ngoe e sebetsa kamoo e lokelang. Basebeletsi ba sheba likarolo tsohle tsa bohlokoa, tse kang li-rotor, li-liner, li-bearings le li-cheek plates. Ba batla matšoao a ho senyeha kapa ho senyeha. Sehlopha se hlahloba hore na liboutu le li-fasteners li tiile le hore na likarolo li kopane hantle. Ba boetse ba sheba liphetoho tsa tšebeliso ea matla kapa li-blockages. Haeba ba fumana ho hong ho phoso, ba etsa liphetoho kapele. Ho hlahlojoa khafetsa le ho ba le likarolo tse setseng ho thusa ho boloka crusher e sebetsa hantle.

Keletso:Rotate mohlahare o shoa ka mor'a lihora tse 50-200, ebe lihora tse ling le tse ling tse 400-500, ho lelefatsa bophelo ba bona le ho boloka ts'ebetso e phahame.

Litokomane le ho Boloka Rekoto

Lirekoto tse ntle li thusa lihlopha ho lekola bophelo ba likarolo tsa liaparo tsa Crusher. Basebetsi ba nka lifoto tsa khoeli le khoeli ho shebella mekhoa ea ho apara. Ba ngola lintlha tse kang mochini oa crusher, mohlala, nomoro ea serial le sebaka. Ba boetse ba tlaleha matsatsi a tlhahlobo, hore na ke mang ea entseng mosebetsi, le hore na crusher e sebelitse lihora tse kae ho tloha cheke ea ho qetela. Lihlopha li sebelisa lisebelisoa tsa digital ho boloka tlhahisoleseding ena le ho e bapisa ha nako e ntse e ea. Lirekoto tsena li thusa ho bona mekhoa, ho rala tlhokomelo ea nako e tlang, le ho fihlela melao ea polokeho.

Koetliso le Tlhokomelo ea Likarolo tsa Crusher Wear

Bohlokoa ba Koetliso ea Kamehla

Koetliso ea kamehla e boloka motho e mong le e mong a sireletsehile a bile a itšepa ha o sebetsa le likarolo tsa liaparo tsa Crusher. Lenaneo le matla la koetliso le akaretsa lihlooho tse ngata:

- Lihlopha li ithuta mokhoa oa ho fepa li-crusher ka tsela e nepahetseng ea ho qoba ho jara.

- Motho e mong le e mong o tlameha ho sebelisa lisebelisoa tsa ts'ireletso joalo ka likatiba tse thata, likhalase tsa tšireletso le limaske tsa lerole.

- Basebeletsi ba utloisisa melao ea polokeho ea sebaka, joalo ka ho se be libakeng tse qheletsoeng ka thoko le matšoao a latelang.

- Koetliso e kenyelletsa tlhahlobo ea letsatsi le letsatsi,apara licheke tsa likarolo, le mokhoa oa ho sebelisa mehato ea lockout/tagout.

- Basebelisi ba qala ho sebelisa lisebelisoa tse ncha, joalo ka li-remote control le sisteme ea ho koala e ikemetseng.

- Ho tsoela pele ho ithuta le ho fana ka setifikeiti ho thusa basebetsi ho boloka lisebelisoa tse ncha le melao ea polokeho.

- Lihlopha tse koetlisitsoeng hantle li na le likotsi tse fokolang 'me li boloka mechine e sebetsa nako e telele.

Koetliso e nepahetseng e boetse e ruta tsela e nepahetseng ea ho tšoara le ho kenya likarolo, e thusang ho thibela tšenyo le ho boloka bohle ba sireletsehile.

Mekhoa ea Tlhokomelo e Reriloeng

Tlhokomelo e hlophisitsoenge thusa ho roala likarolo tsa Crusher hore li tšoarelle nako e telele le ho boloka crusher e sebetsa hantle. Lihlopha li latela moralo o kenyeletsang:

- Ho hlahloba mekhoa ea ho apara le ho hlahloba hore na ha ho na mapetsong kapa liboutu tse hlephileng.

- Li-bearings tsa ho tlotsa le ho hlahloba li-liner beke le khoeli kapa khoeli.

- Ho sebelisa lisebelisoa tse khethehileng ho metha ho senyeha le ho bona mathata esale pele.

- Ho lokisa litlhophiso tsa crusher le ho etsa bonnete ba hore fepa e lekana.

- Ho kenya likarolo ka nepo le ho hlahloba ho tsamaisana.

- Koetlisa motho e mong le e mong ka ts'ebetso e sireletsehileng le ho tsebahala ka ho apara.

- Ho sebelisa likarolo tsa boleng ho tsoa ho barekisi ba tšepahalang.

- Ho boloka likarolo tse ling setokong le ho li sala morao ka software.

Kemiso e ntle ea tlhokomelo e boetse e kenyelletsa ho hloekisa, ho hlahloba ho sisinyeha, le ho sireletsa likarolo lerōleng le mongobo.

Tsoelo-pele ea Ntlafatso le Tšireletseho Setso

Ntlafatso e tsoelang pele e bolela ho lula u batla litsela tse betere tsa ho sebetsa. Lihlopha li sebelisa lisebelisoa tse ncha le mekhoa e sireletsehileng ho fetola likarolo ka potlako le ka kotsi e fokolang. Ba khetha lisebelisoa tse fokotsang lerata le ho thothomela, ho etsa hore mosebetsi o bolokehe. Ho beha leihlo kamehla ho thusa lihlopha hore li nkele likarolo tse tsofetseng pele li baka mathata. Tloaelo e matla ea polokeho e tlisa melemo ea 'nete:

- Likotsi le likotsi tse fokolang

- Litšenyehelo tse tlase tsa tlhokomelo

- Nako e fokolang ea ho phomola

- Boitšoaro bo botle ba basebetsi

Chelete e 'ngoe le e' ngoe e sebelisoang ho lokisoa ka mokhoa o thibelang e ka boloka ho fihlela ho lidolara tse leshome ho lokisoa. Sebaka sa mosebetsi se sireletsehileng se thusa bohle ho etsa mosebetsi oa bona o motle.

Tšireletseho e bohlokoa mohatong o mong le o mong ha o nkela likarolo tsa liaparo tsa Crusher. Lihlopha li lokisetsa, li hlahloba le ho latela mekhoa e sireletsehileng. Ba hlahloba likarolo ka mor'a ho kenya le ho tsoela pele ho ithuta tsebo e ncha. Ho latela ka tieo litataiso tsa moetsi ho thusa ho thibela likotsi le ho boloka lisebelisoa li sebetsa nako e telele.

Mekhoa e metle e boloka chelete le ho sireletsa basebetsi.

- Lokisetsa pele u qala

- Hlahloba likarolo khafetsa

- Sebelisa mehato e sireletsehileng ea ho tlosa le ho kenya

- Sheba tsohle ka mor'a ho fetola

- Koetlisa lihlopha kamehla

LBH

Ke hangata hakae lihlopha li lokelang ho hlahloba likarolo tsa li-crusher?

Lihlopha li hlahloba likarolo tsa liaparo beke le beke. Ho hlahloba khafetsa ho thusa ho bona tšenyo e sa le pele le ho boloka crusher e sebetsa ka mokhoa o sireletsehileng.

Ke thepa efe ea tšireletso eo bohle ba e hlokang?

Basebetsi ba roala likatiba tse thata, likhalase tsa tšireletso, liatlana, libutsi tse menoana ea tšepe le li- vest tse bonahalang haholo. Tšireletso ea ho utloa e thusa libakeng tse lerata.

A na ho na le motho ea ka sebelisang likarolo tsa khale tsa li-crusher?

Che, lihlopha ha lia lokela ho sebelisa likarolo tse tsofetseng hape. Likarolo tsa khale li robeha habonolo 'me li baka likotsi tsa polokeho. Kamehla sebelisa tse ncha, tse lumelletsoeng ke moetsi.

Nako ea poso: Aug-13-2025