A cone crushere itšetlehile ka thepa ea boemo bo phahameng ho sebetsana le mesebetsi e boima, haholo-holo ea eonalikarolo tsa cone crusher. Tšepe ea manganese, haholo-holo tšepe ea Hadfield, e laola kaho ea eona. Sesebediswa sena se fana ka matla a makatsang le khanyetso ea ho roala, ka manganese e fetang 12% e thatafalang nakong ea ts'ebeliso. Li-composite tsa tšepe le tsa ceramic li boetse li matlafatsa ho tšoarella ha "cone crusher" e netefatsang hore e mamella khatello e matla le maemo a mahlaba.

Lintlha tsa bohlokoa

- Manganese tšepeke thepa ea mantlha ea li-cone crushers. E matla haholo 'me e hanela ho khathala.

- Lisebelisoa tse matla joalo ka metsoako ea ceramic li etsa hore likarolo li tšoarelle nako e telele. Li boetse li thusa sehatsetsing sa conesebetsa hantle mme o hloka ho lokisoa hanyane.

- Ho khetha lisebelisoa tse nepahetseng le ho lokisa maemo ho ka thusa haholo. E etsa hore crusher e sebetse hantle mme e tšoarelle nako e telele.

Likarolo tsa Cone Crusher le Lisebelisoa tsa tsona

Mantle le Concaves

Themantle le concaveske likarolo tsa bohlokoa tsa li-cone crusher tse sebetsanang ka kotloloho le thepa e pshatlehang. Likarolo tsena hangata li entsoe ka tšepe ea manganese, e thatafatsang tlas'a khatello le ho hana ho roala. Mantle a lutse ka holim'a moqomo o moholo, ha li-concaves li etsa sekotlolo se emeng ho e potoloha. Hammoho, ba theha kamore e pshatlehang moo mafika a hatelloang le ho robeha.

Litlaleho tsa ts'ebetso li bonts'a hore litefiso tsa ts'ebetso ea likarolo tsena li ipapisitse le lintlha tse kang thepa ea tšepe le metrics ea ts'ebetso. Likarolo tse phahameng tsa ho roala holim'a li-concave liners hangata li hlaha ka har'a mela e bohareng le e ka tlaase, ha mantle a ntse a apara ka ho lekana. Sena se totobatsa bohlokoa ba ho khetha lisebelisoa tse tšoarellang le ho ntlafatsa litlhophiso tsa crusher ho lelefatsa bophelo ba likarolo tsena.

Main Shaft le Eccentric Bushing

Themolamu o ka sehloohong'me eccentric bushing ke mokokotlo oa ts'ebetso ea cone crusher. Mokotla o ka sehloohong o tšehetsa seaparo sa ka holimo 'me o fetisetsa matla a ho senya, ha sehlahla sa eccentric se lumella seaparo hore se tsamaee ka mokhoa oa gyratory. Likarolo tsena hangata li entsoe ka tšepe e matla le lialloys tsa boronse ho mamella khatello e matla le matla a ho potoloha a amehang.

- Litaba tse tloaelehileng ka eccentric bushing li kenyelletsa:

- Ho chesa ho feteletseng ha oli e tlotsang

- Lifaele tsa boronse skrineng sa hydraulic unit

- Ho koaleha ka botlalo ha crusher

- Lintho tse tlatsetsang ho felloa ke matla ha bushing:

- Lubrication e fosahetseng

- Li-liner tse fosahetseng kapa litlhophiso tse fosahetseng

- Litefiso tse feteletseng ka thepa ea phepelo

Ha motho a khathala ka ho feteletseng, litsebi li lokela ho tseba sesosa sa motso, li hloekise le ho bentša moqomo o moholo, ebe li lekanya likarolo tse senyehileng bakeng sa ho nkeloa sebaka. Tlhokomelo e nepahetseng e tiisa hore likarolo tsena tsa cone crusher li sebetsa hantle ebile li tšoarella nako e telele.

Frame le Tramp Release Mechanism

Foreimi e fana ka tšehetso ea sebopeho bakeng sa likarolo tsohle tsa cone crusher. Hangata e entsoe ka tšepe e entsoeng ka tšepe kapa tšepe ho netefatsa botsitso le ho mamella meroalo e boima. Ka lehlakoreng le leng, mochine oa ho lokolla tramp o sireletsa sekontiri ho tloha tšenyo e bakoang ke lisebelisoa tse ke keng tsa senyeha joaloka lithōle tsa tšepe.

Mochine ona o sebelisa lisebelisoa tsa hydraulic ho lokolla khatello le ho lumella thepa e sa tsitsang hore e fete ka mokhoa o sireletsehileng. Hangata bahlahisi ba sebelisa metsoako ea ceramic le tšepe ea boemo bo phahameng bakeng sa likarolo tsena ho netefatsa hore li tšoarella le ho tšepahala. Foreimi e entsoeng hantle le mokhoa oa ho lokolla tramp o kenya letsoho ho sebetsa hantle le polokeho ea crusher nakong ea ts'ebetso.

Lebaka Leo ka Lona Lisebelisoa Tsena

Durability le Wear Resistance

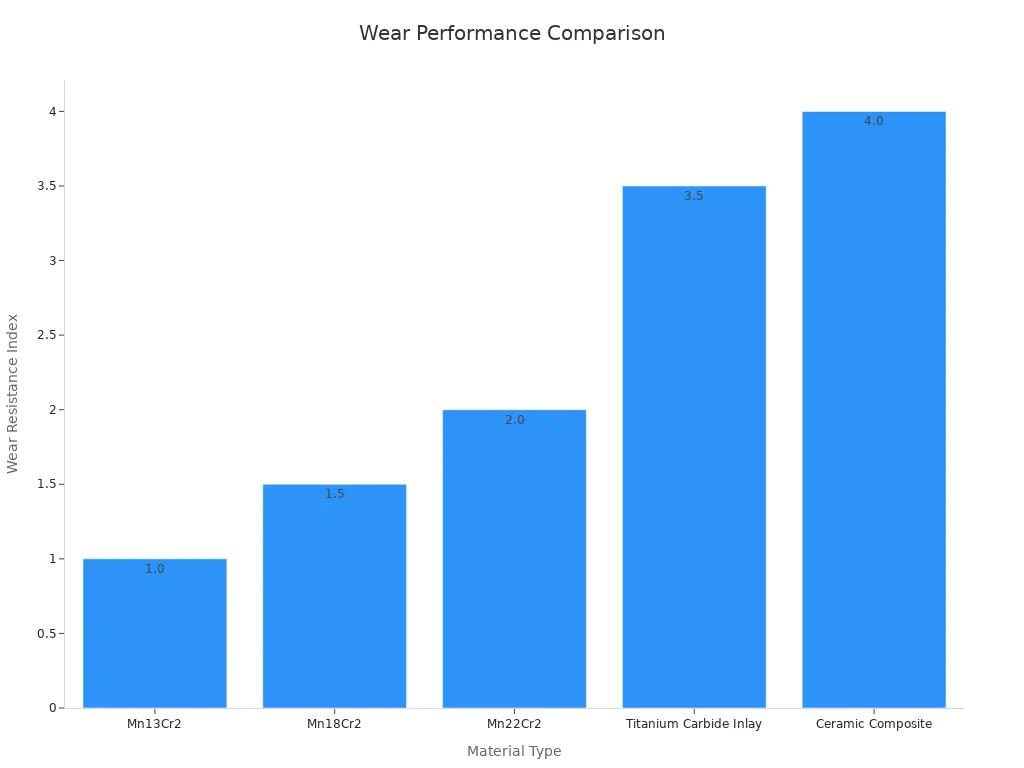

Likarolo tsa li-cone crusher li tobana le ho khathala ho feteletseng le ho taboha nakong ea ts'ebetso. Ho loantša sena, bahlahisi ba sebelisa lisebelisoa tse kangtšepe ea manganese le metsoako ea ceramic. Tšepe ea manganese, haholo-holo limaraka tse joalo ka Mn13Cr2 le Mn18Cr2, e thatafala ha e le tlas'a khatello ea maikutlo, e etsa hore e be e loketseng bakeng sa ho pshatla lintho tse hohlang. Ka lehlakoreng le leng, li-composites tsa Ceramic li fana ka boima bo phahameng haholo 'me li boloka boemo ba tsona bo bohale bo sithabetsang esita le maemong a boima.

| Mofuta oa Boitsebiso | Ho thatafala (HRC) | Apara Resistance Index | Impact Resistance | Ho Lebeletsoe Nako ea Bophelo (lihora) |

|---|---|---|---|---|

| Mn13Cr2 | 18-22 | 1.0 | ★★★★★ | 800-1200 |

| Mn18Cr2 | 22-25 | 1.5 | ★★★★☆ | 1200-1800 |

| Motsoako oa Ceramic | 60-65 | 4.0 | ★☆☆☆☆ | 3000-4000 |

Lisebelisoa tsena li netefatsa hore crusher e khona ho sebetsana le ts'ebeliso ea nako e telele ntle le ho nkeloa sebaka khafetsa, e fokotsa litšenyehelo tsa nako le tlhokomelo.

Matla bakeng sa Likopo tsa Khatello e Phahameng

Li-crusher tsa li-cone li sebetsa tlas'a khatello e matla, haholo-holo ha li sebetsana le lisebelisoa tse thata tse kang quartz kapa granite.Matla a phahameng a tšepe le titanium carbideli-inlays li sebelisoa hangata bakeng sa likarolo tse kang shaft e kholo le mantle. Ka mohlala, li-inlay tsa Titanium carbide, li ntlafatsa ho hanyetsa ho apara ka makhetlo a 1.8 le ho ba le tšusumetso e matla ka makhetlo a 8.8 ha ho bapisoa le lisebelisoa tsa setso. Matla ana a tiisa hore crusher e khona ho sebetsana le lits'ebetso tsa khatello e phahameng ntle le ho sekisetsa ts'ebetso.

Ho ikamahanya le maemo ho Litlhoko tse fapaneng tsa ho hatakela

Mesebetsi e fapaneng ea ho senya e hloka lisebelisoa tse ka ikamahanyang le maemo a fapaneng. Mohlala, Mn18Cr2 e sebetsa hantle ka ho sebetsana le thepa e sa tsitsang e nang le litšila ka lebaka la ts'ebetso ea eona e matla ea ho hanyetsa. Li-composites tsa ceramic li loketse hantle bakeng sa ho pshatla ha thepa e thata haholo. Liteko tsa ts'ebetso tse sebelisang lipapiso tsa lipalo, joalo ka mokhoa oa discrete element (DEM), li bonts'itse hore ho ntlafatsa liparamente joalo ka lebelo la ho potoloha le li-angles tsa cone ho ka ntlafatsa ho ikamahanya le maemo. Mohlala, mochini o silafatsang oa likhoune oa Y51, o fihletse tlhahiso e phahameng ka ho fetesisa ka sekhahla sa 1.5° le lebelo la ho potoloha la 450 rad/min.

Ka ho khetha lisebelisoa le litlhophiso tse nepahetseng, likarolo tsa cone crusher li ka fihlela litlhoko tse fapaneng tsa ts'ebetso ha li ntse li sebetsa hantle.

Kamoo Lisebelisoa li Amang Tšebetso ea Crusher

Sebetsa se Ntlafetseng le Bophelo bo Bolelele

Lisebelisoa tse sebelisoang likarolong tsa cone crusher li bapala karolo e kholo ho ntlafatseng ts'ebetso le ho lelefatsa bophelo ba mochini. Lisebelisoa tsa boleng bo holimo joalo ka tšepe ea manganese le metsoako ea ceramic e netefatsa hore likarolo li khona ho sebetsana le ts'ebeliso e boima ntle le ho khathala kapele. Ka mohlala, lisebelisoa tse sa tsoeng li ka nka nako e telele ka makhetlo a mabeli ho isa ho a mane ho feta tsa setso, ho fokotsa tlhokahalo ea ho nkeloa sebaka khafetsa.

| Bopaki | Tlhaloso |

|---|---|

| Lisebelisoa tsa boleng bo phahameng | E sebelisetsoa ho etsa likarolo tse tšoarellang. |

| Lisebelisoa tse sa tl'o roala | Ntlafatsa ho tšoarella, ho tšoarella makhetlo a 2 ho isa ho a 4 nako e telele. |

Lisebelisoa tse tšoarellang li boetse li fokotsa tahlehelo ea matla nakong ea ts'ebetso. Liphuputso li bonts'itse hore li-crushers tse hahiloeng ka thepa e matla ha li na ho senyeha ho fokolang le ho taboha, ho bolelang hore li boloka ts'ebetso ea tsona ha nako e ntse e ea. Ho tšoarella hona ho etsa bonnete ba hore crusher e sebetsa hantle, le tlas'a maemo a thata.

| Bopaki | Tlhaloso |

|---|---|

| Li-crushers tsa boleng bo holimo | E entsoe hore e tšoarelle ka lisebelisoa tse hananang le abrasion. |

| Lisebelisoa tse matla | E lebisa ho fokotseng ho senyeha, ho ntlafatsa ts'ebetso. |

Tlhokomelo e Fokotsoeng le Nako ea ho Pholoha

Ho hlokomeloa khafetsa ho ka sitisa ts'ebetso le ho eketsa litšenyehelo. Ka ho sebelisa thepa e matla le e sa senyeheng, bahlahisi ba fokotsa tlhokahalo ea ho lokisoa. Ka mohlala, tšepe ea manganese e thatafala tlas'a khatello ea kelello, e etsa hore e be e loketseng bakeng sa likarolo tse kang mantle le li-concave. Thepa ena e fokotsa sekhahla sa ho roala, e lumellang crusher hore e sebetse nako e telele ntle le tšitiso.

Boithuto bo boholo ka 1982 bo ile ba lekanya matla a ho robeha le litšobotsi tsa ho robeha ha tšepe ea li-crusher tsa tlhahiso. Liphello li bontšitse hore ho sebelisa thepa ea boleng bo phahameng ho fokolitse haholo litšitiso tsa ts'ebetso. Lipapiso tse tsoang thutong li ile tsa lekoa ka mekhoa e matla ea pendulum, e tiisang bokhoni ba thepa ea ho mamella maemo a feteletseng.

Ho feta moo, khetho ea thepa e ama tsela eo crusher e sebetsanang hantle le maemo a fapaneng a cavity. Li-crusher tse sebetsang ka likheo tse felletseng le lisebelisoa tsa rock tse thata li bonts'a katleho ea tlhahiso. Ka lehlakoreng le leng, ts'ebetso ea "low-cavity" e nang le lisebelisoa tsa majoe a bonolo hangata e lebisa ts'ebetsong e fapaneng, e hlokang hore ho etsoe liphetoho khafetsa.

| Boemo ba Cavity | Mofuta oa Boitsebiso | Liphello Tse Shebiloeng |

|---|---|---|

| Mokoti o tlase | Lefika le bonolo | Tšebeliso e eketsehileng ea matla. |

| Mokoti o phahameng | Lefika le thata | Thepa e ntlafalitsoeng ea phokotso. |

Ntlafetseng Crushing Precision

Lisebelisoa tse nepahetseng li boetse li ntlafatsa ho nepahala ha mokhoa oa ho senya. Mohlala, li-composite tsa ceramic li boloka boemo ba tsona bo bohale bo sithabetsang, le kamora ts'ebeliso ea nako e telele. Ho tsitsana hona ho etsa bonnete ba hore crusher e hlahisa thepa ea boholo bo lekanang, e leng ea bohlokoa bakeng sa liindasteri tse kang tsa kaho le tsa merafo.

Sistimi ea taolo ea ho fokotsa boholo ka boiketsetso e ntlafatsa ho nepahala. Li-crusher tse nang le lisebelisoa tsena li na le phapang e fokolang ea 38-46% ho metrics ea ts'ebetso. Tlhahiso e tsitsitseng e boetse e matlafatsa ts'ebetso ea potoloho ka 12-16%, e leng ho etsang hore crusher e tšepahale haholoanyane.

| Liphuputso tsa Bohlokoa | Tšusumetso ho Ts'ebetso |

|---|---|

| Taolo ea ho fokotsa boholo bo itekanetseng | 38-46% phapano e tlase ho metrics ea ts'ebetso. |

| Ho lumellana ha tlhahiso | 12-16% keketseho ea ts'ebetso ea potoloho. |

Ka ho kopanya lisebelisoa tse tsoetseng pele le boenjiniere bo nepahetseng, likarolo tsa cone crusher li fana ka ts'ebetso e ikhethang. Motsoako ona ha o ntlafatse ho nepahala ha ho sila feela empa hape o netefatsa hore mochini o kopana le litlhoko tsa lits'ebetso tse fapaneng.

Lisebelisoa tse sebelisoang ho li-cone crushers li bohlokoa bakeng sa ho tšoarella le ho sebetsa hantle ha tsona. Tšepe ea manganese, tšepe ea khabone, metsoako ea ceramic, le tšepe e entsoeng ka tšepe li netefatsa hore mechini ena e khona ho sebetsana le lits'ebetso tse thata le ho hana ho khathala ha nako e ntse e ea.

- Li-crushers tsa li-cone li ntlafatsa matla a matla ka 10-30%, li fokotsa litšenyehelo tsa ts'ebetso.

- Li-crusher li boloka tlhahiso e tsitsitseng bakeng sa boholo bo lekanang ba thepa, esita le ka mefuta e fapaneng ea moralo oa kamore.

- Litsebi tsa indasteri li totobatsa ho ntlafatsa likarolo tsa moaparo le litlhophiso tsa kamore bakeng sa ts'ebetso e ntle le bophelo bo bolelele.

Khetho e nepahetseng ea thepa ha e phahamise ts'epahalo feela empa hape e ts'ehetsa tlhokahalo ea indasteri ea merafo ea ho lokisa lithane tse fetang limilione tse 1.3 tsa majoe ka selemo. Ka ho leka-lekanya moralo le mefuta e fapaneng ea ts'ebetso, li-cone crusher li fana ka sephetho se ts'oanang lits'ebetsong tse fapaneng.

LBH

Likarolo tsa bohlokoa tsa cone crusher ke life?

Mantle, concave, main shaft, eccentric bushing, le foreimi ke likarolo tsa bohlokoa. Karolo ka 'ngoe e phetha karolo ea bohlokoa ts'ebetsong ea ho senya.

Lisebelisoa li ama ts'ebetso ea likarolo tsa cone crusher joang?

Lisebelisoa tsa boleng bo holimo li ntlafatsa ho tšoarella,fokotsa matla, le ho ntlafatsa ts'ebetso. Ba netefatsa hore crusher e sebetsa hantle, leha maemo a le thata.

Ke hobane'ng ha tšepe ea manganese e atisa ho sebelisoa likarolong tsa cone crusher?

Litšepe tsa manganese lia thatafala ha li le tlas'a khatello ea maikutlo, 'me li etsa hore e be sebaka se loketseng bakeng sa ho pshatla lintho tse chehang. Ho tšoarella ha eona ho eketsa nako ea bophelo ea likarolo tsa bohlokoa joalo ka mantle le li-concave.

Nako ea poso: Jun-03-2025